-

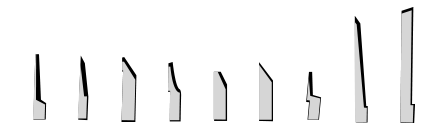

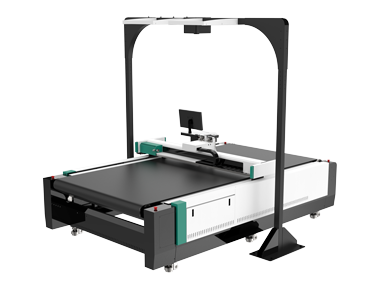

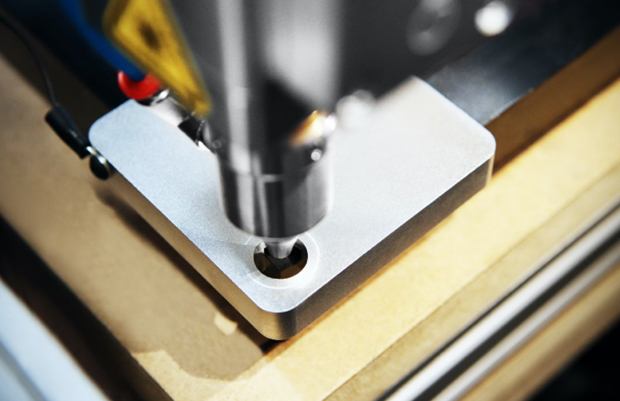

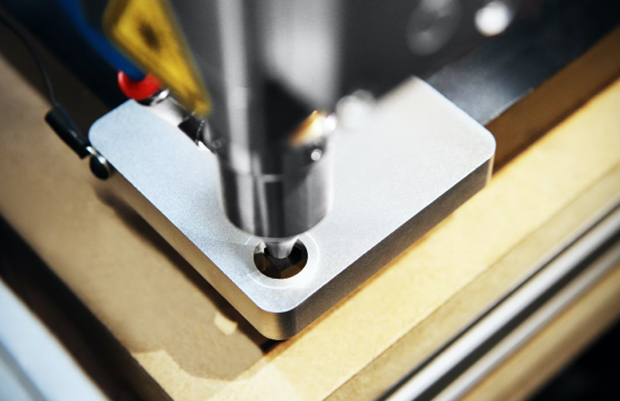

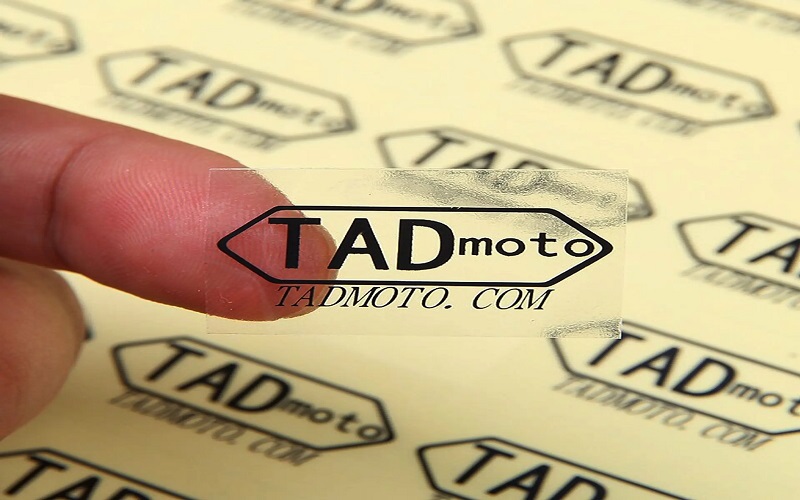

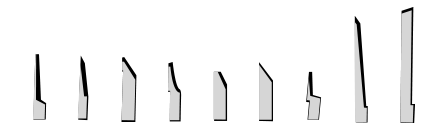

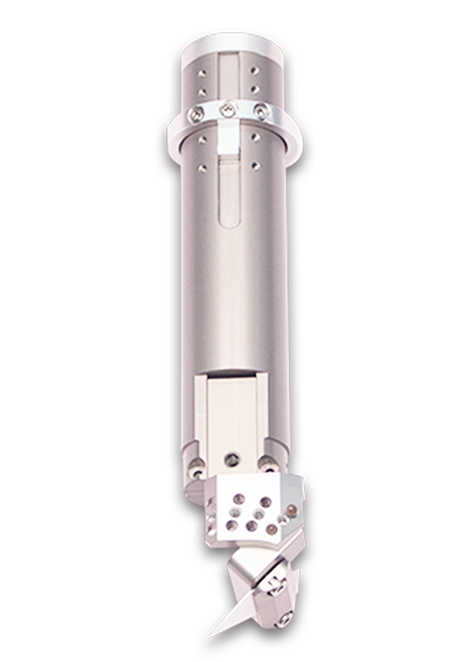

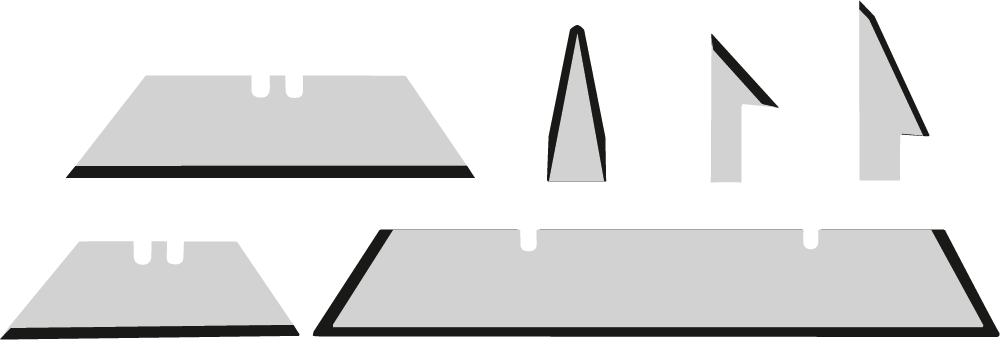

The Electrical Oscillating Tool is super suitable for cutting the material of medium density.Coordinated with various kinds of blades, applied for cutting different materials

-

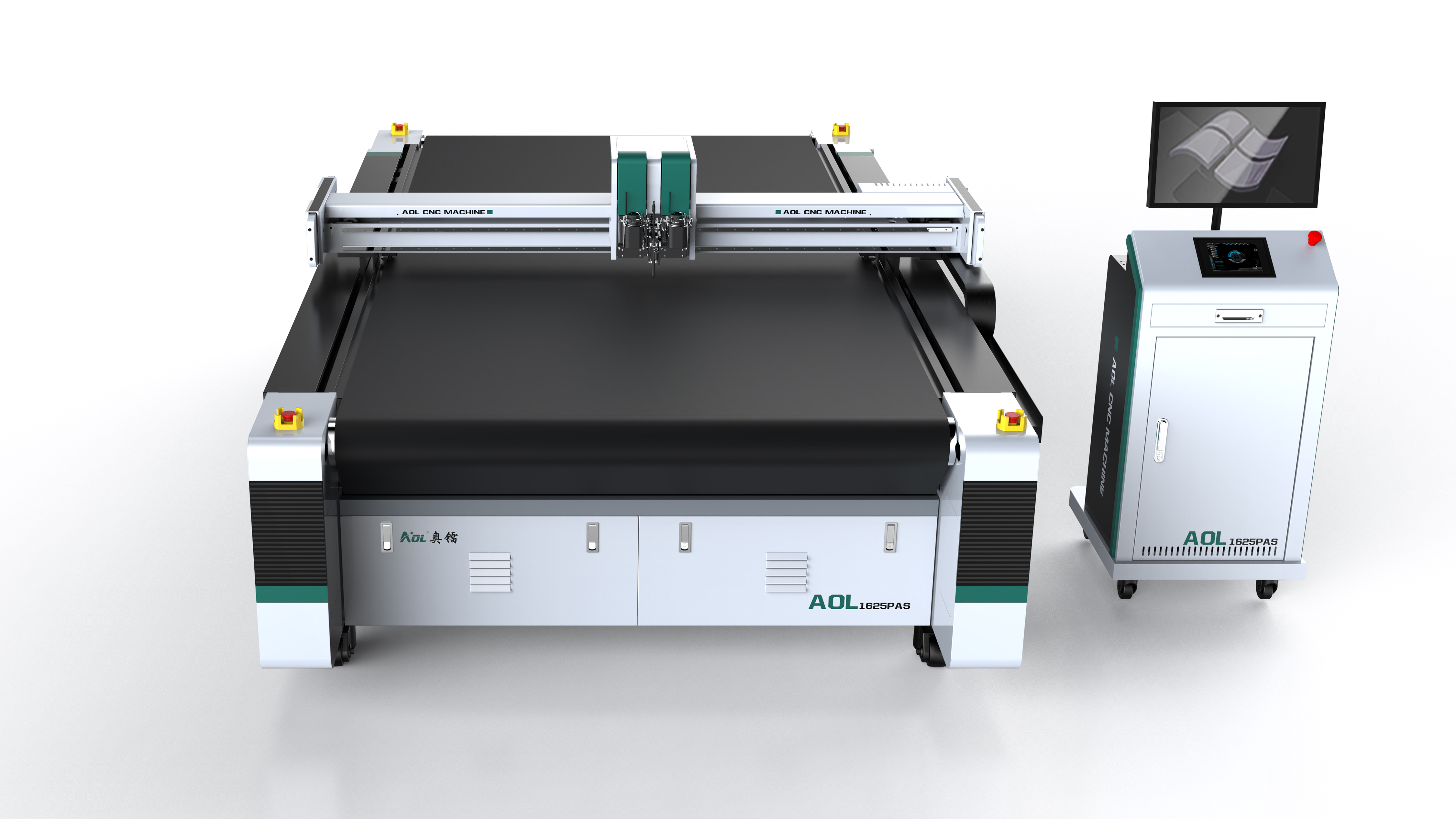

Applicable to composite materials, clothing, leather, carpet, advertising packaging, etc