-

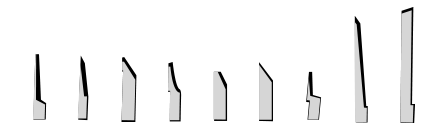

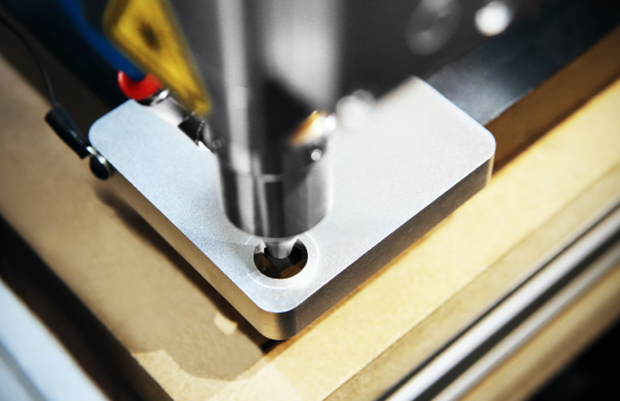

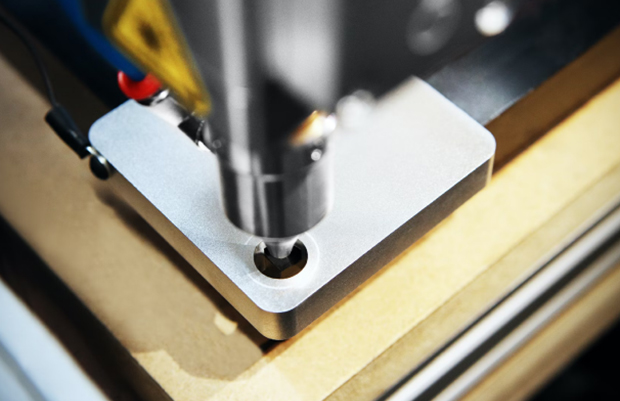

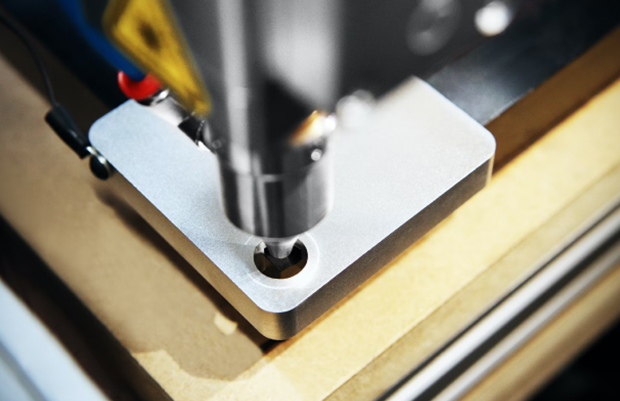

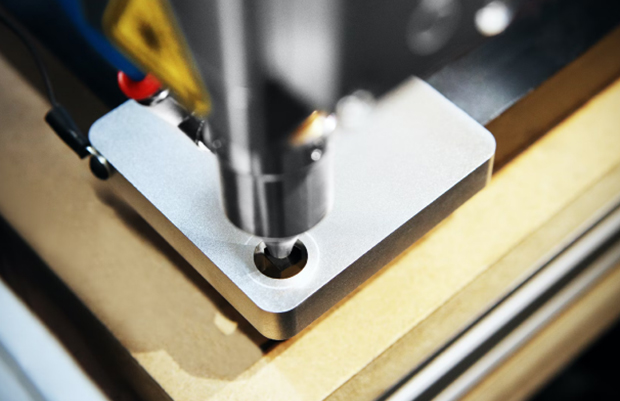

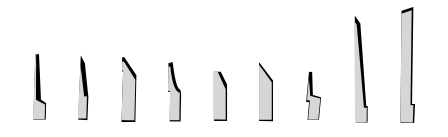

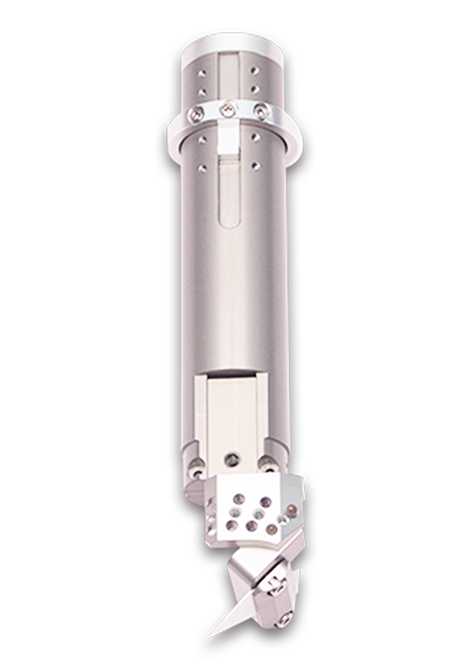

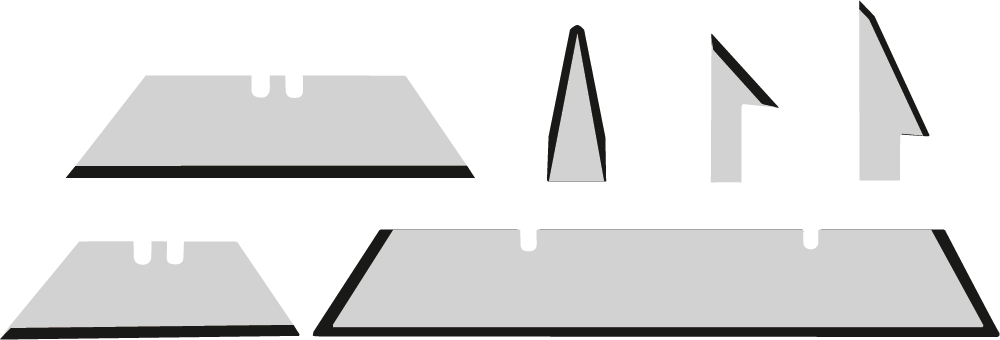

The Electrical Oscillating Tool is super suitable for cutting the material of medium density.Coordinated with various kinds of blades, applied for cutting different materials

-

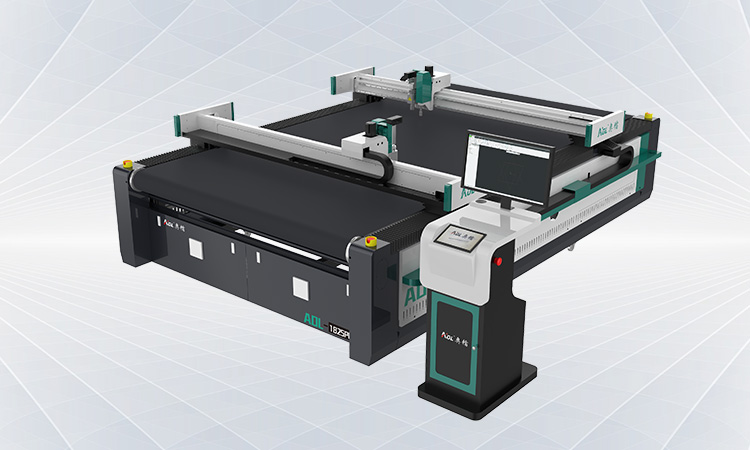

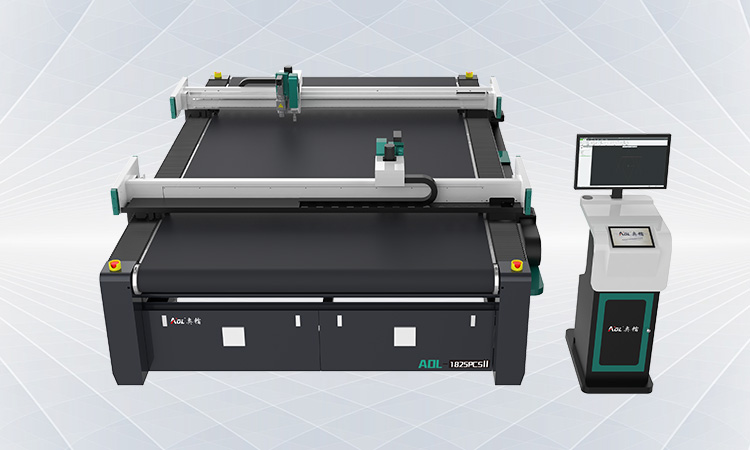

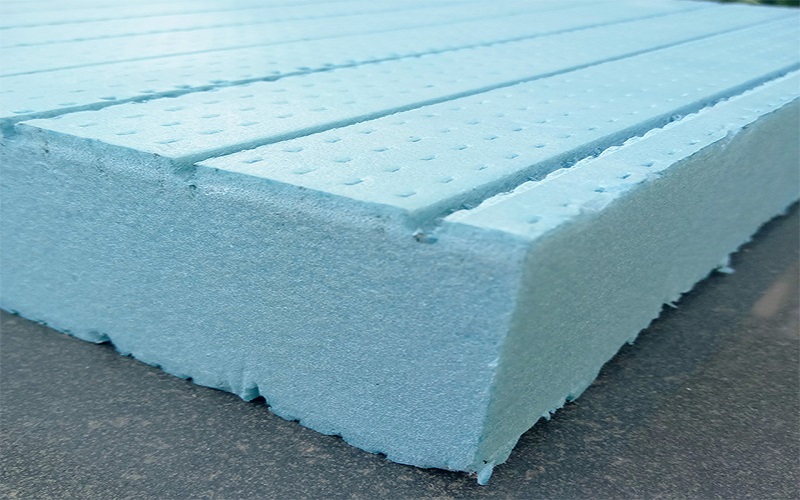

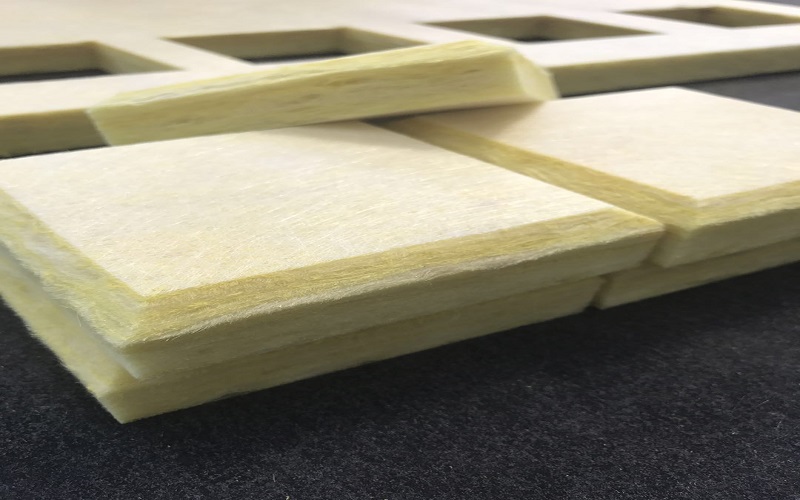

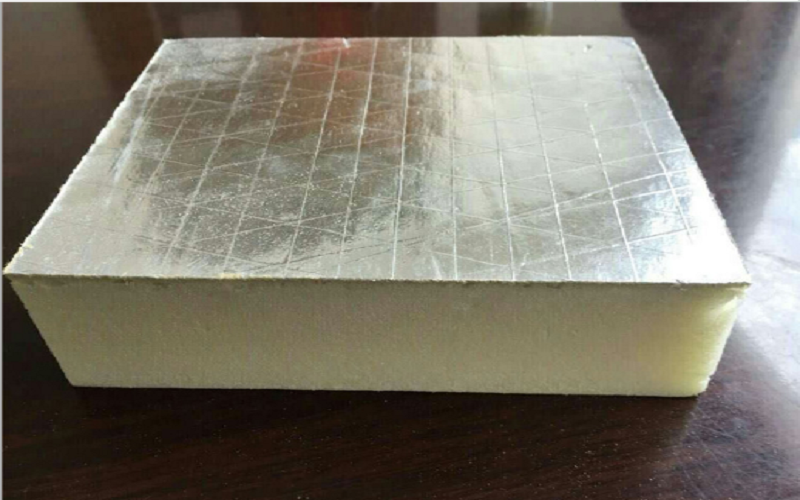

Applicable industries: Corrugated, Cardboard, Carpet, Foam board, Honeycomb board, Car Mat, Seat Cover, KT board, Gray board, Composite Materials, Leather, Fabric, etc