For the traditional luggage and cloth bag industry, how to get rid of the poor cutting accuracy and low efficiency has become a great problem, especially in today's economic downturn, reducing cost and increasing efficiency is our primary consideration. The high labor cost and material waste have greatly increased the production cost and increased the burden of enterprises in a disguised form.

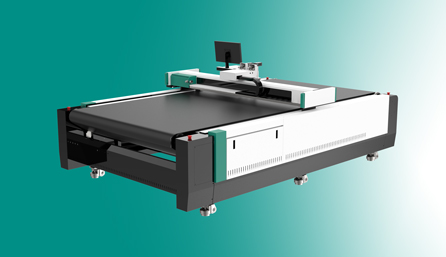

How to solve this problem, we must seek a breakthrough from the outside. The vibrating knife cutting machine adopts an integrated cutting system and computer-controlled data cutting. It has high cutting precision and intelligent material saving of more than 15%, helping the enterprise overcome the production difficulties.

Features of automatic bag feeding and cutting machine:

1. The paperboard is input through the SLR camera or digital scanner, and the 1:1 electronic version is output to ensure the accuracy of the paperboard;

2. It is equipped with automatic setting out system for clothing bags, which can automatically add or subtract dimensions, splicing, deletion, etc. according to different customer needs;

3. The template management can realize automatic typesetting and improve the utilization rate of cloth to the greatest extent. The discharging speed can reach about 10 times of manual work, and the length and utilization rate of cloth can be clearly seen;

4. The data is transmitted to the cutting machine through intelligent software, and the equipment realizes the automatic feeding function without manual paving and automatic cutting, which saves manpower and greatly improves the work efficiency;

5. The integrated platform adopts the composition principle of honeycomb, which is firm, anti-corrosion, durable, sound-absorbing and heat insulation.

The equipment adopts the integrated welding process, which avoids the metal fatigue caused by the long-term operation of the equipment (the accuracy and efficiency will decline). It supports the addition of camera automatic identification system to enable the equipment to realize the irregular layout of leather. The intelligent layout system supports the calculation of the utilization rate of materials in leather, so as to truly achieve controllable production and feasible growth.

Luggage material cutting machine is suitable for cutting leather, leather, cloth and other materials. One machine replaces 4-6 workers. The most important thing is to make production controllable, no longer limited by talents, and let digital production enter small and medium-sized manufacturers.