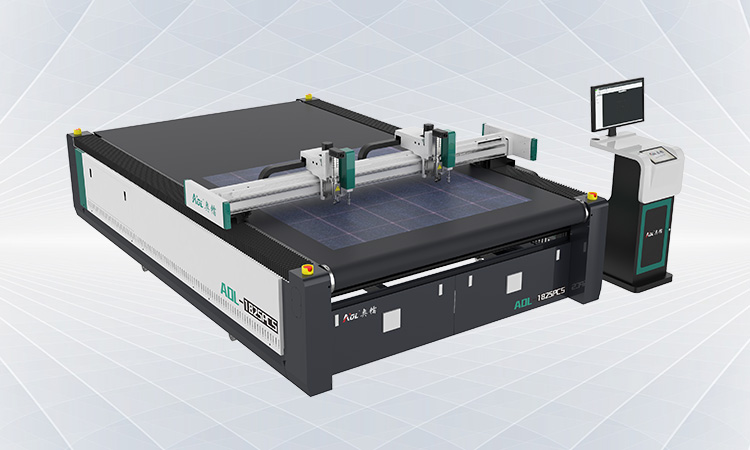

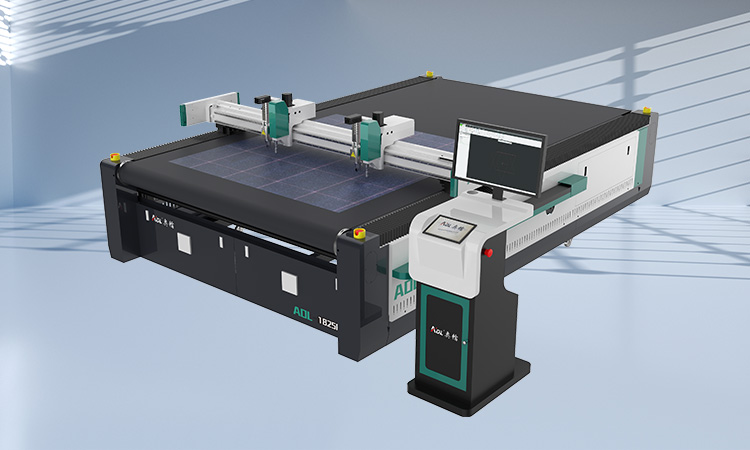

Leather cutting machine, also known as vibrating knife cutting machine, is a professional cutting equipment for leather goods, supports independent DIY plate making, no need for mold or cardboard, one-click import and cutting, very suitable for large, medium and small manufacturers to customize or mass produce leather goods. The leather cutting machine adopts computer plate making, typesetting and data cutting, which is convenient and fast. The equipment has automatic typesetting software, which can realize automatic material-saving typesetting and cutting. It has automatic feeding, automatic cutting, automatic punching, and automatic cutting system to realize one-time cutting.

The leather cutting machine is suitable for single-layer cutting of leather, multi-layer cutting of leather, suitable for various special-shaped cutting, which can save the cost of mold, pattern, labor, etc., and multi-layer cutting can be efficient and material-saving. At present, the leather cutting machine has been maturely applied to various Large factories are used to process leather shoes, leather bags, leather clothing and other industries, and many manufacturers are also increasing equipment.

Leather cutting machine parameters:

|

Technical parameters / model |

AOL-1625 |

AOL-1825 |

|

Effective working area |

1600x2500mm |

1800x2500mm |

|

Multi-function tool |

Oscillating knife, round knife, pneumatic knife, drag knife, half cutting knife, press wheel, V-CUT Knife Tool, milling cutter, drawing marker pen, ink cartridge inkjet, cursor positioning, camera positioning edge patrol |

|

| safety devices |

Four corners emergency stop, anti-collision safety device using infrared induction, safe and reliable |

|

| Cutting tool configuration | Pneumatic knife、punching tool | |

|

Cutting speed |

50-100mm/s |

|

|

Cutting thickness |

≤15mm Other thicknesses can be customized according to the material |

|

|

Applicable materials |

Genuine leather, PU leather, PVC leather and other leather or matching leather materials |

|

|

Material fixing method |

Vacuum partition adsorption |

|

|

Transmission port |

Network port |

|

|

Transmission system |

The X\Y axis is divided into two kinds of rack or belt |

|

|

rated power |

11kw |

|

|

Rated voltage |

380V±10%/220V±10% Optional |

|

|

Control System |

Chinese and English LCD touch screen |

|

|

Operating environment |

Operating environment Temperature 0-40°C Humidity 20%-80%RH |

|

|

Support file format |

AI、PLT、DXF、PDF、 PCE、XML |

|

| Overall size |

3600x2400x1200mm |

3600x2600x1200mm |

| Other configuration | Panasonic servo motor, high-precision helical gear reducer, Taiwan Yintai guide rail, German Henry Ann rack, Omron sensor, Schneider low-voltage electrical appliances, Taiwan Mean Well power supply, German cable, 42mm adsorption platform, automatic feeding, Taiwan guide rail, energy-saving fan | |

The leather cutting machine has the advantage of saving time, mainly because the automatic cutting does not require a mold, which saves a lot of time in making the knife mold.

Save labor costs, only one person is required to operate the typesetting, and two machines can be operated at the same time, and one machine can save at least 4-6 workers.

The equipment has a system to intelligently optimize typesetting and cutting, providing better cutting and filling paths, saving more than 30% of materials.

The machine can distinguish grades according to leather materials, support partition classification, directional nesting and cutting, and support multiple nesting rules.

Functional advantages of leather cutting machine:

1. It integrates the functions of multi-layer high-efficiency cutting, intelligent automatic typesetting, automatic transmission, and continuous operation, which can meet the needs of shoe industry, luggage industry, automobile mat industry, furniture industry, etc. cutting needs of the industry.

2. Using imported accessories, the cutting precision is higher and the stability is stronger.

3. It has an automatic typesetting and cutting system independently developed by a professional team to maximize the automatic typesetting and cutting needs of PU and efficiently improve the utilization rate of leather materials.

4. Highly integrated multi-functional machine head, which can complete cutting, punching, drawing and marking processes at the same time.

The times are developing, and the progress of intelligent equipment is inevitable. In the era of personalized customization, the old-fashioned punching machine and labor will be eliminated, so the leather cutting machine will become the mainstream in the future.

If there is anything else you want to know, please contact us and we will answer you as soon as possible!