High-performance composite materials began to be applied to the secondary load-bearing structure of aircraft on a large scale, including flight control surfaces such as ailerons, elevators, rudders and spoilers. Because of the unstable output and low efficiency caused by manual problems, the aviation composite material cutting machine has taken an extremely important step on the road of intelligence.

Commonly used aviation composite materials include carbon fiber, glass fiber, boron fiber and aramid fiber. Carbon fiber is a new type of fiber material with high strength and high modulus fiber with a carbon content of more than 95%. With the characteristics of corrosion resistance and high film content, it is an important material in national defense and civil applications.

Glass fiber is an inorganic non-metallic material with excellent performance. There are many kinds. The advantages are good insulation, heat resistance, good corrosion and high mechanical strength, but the disadvantages are brittleness and poor corrosion. It is usually used as composite materials. It is widely used in various fields of the national economy.

Aramid fiber composite material is known as the diamond in the global material crown, ranking among the three high-performance materials. Its industrialization process has a crucial impact on my country's national defense construction and leading industrial projects (such as large aircraft, high-speed trains, shipbuilding, electric power, electronic information, building materials, etc.). In the field of military industry, aramid composite materials are widely used in aircraft, ships, submarines and tanks. In the civil field, it is mainly used for high-performance structural parts of aerospace, aviation, high-speed trains and automobiles, large motors and high-end insulating materials for transformers in rail transit, nuclear power, hydropower and power grid engineering, and high-performance thermal insulation and flame retardant materials for buildings. High-end circuit boards and printing, medical materials, etc.

At present, the industry pain points encountered in the cutting process of most composite materials:

1. Special-shaped non-standard orders, product quality and process requirements are high

2. The demand for orders is large, and other methods cannot meet production

3. Special materials are harmful to the human body, and the process must be changed

4. The risk factor of punch processing is large, and there are many types of molds

5. Professional workers are difficult to recruit and manage

6. The company's development needs must improve the existing process

The advantages of aviation composite material cutting machine in the industry:

1. Replace manual work, improve factory environment, and enhance product competitiveness

2. Save time and effort and ensure cutting accuracy

3. Automatic loading and unloading, uninterrupted work, no smoke and dust to replace 3-5 manual labor

4. High precision, fast speed, not limited by cutting patterns, can cut any graphics and patterns

5. Automatic cutting makes work easier and more efficient.

Recommended equipment models:

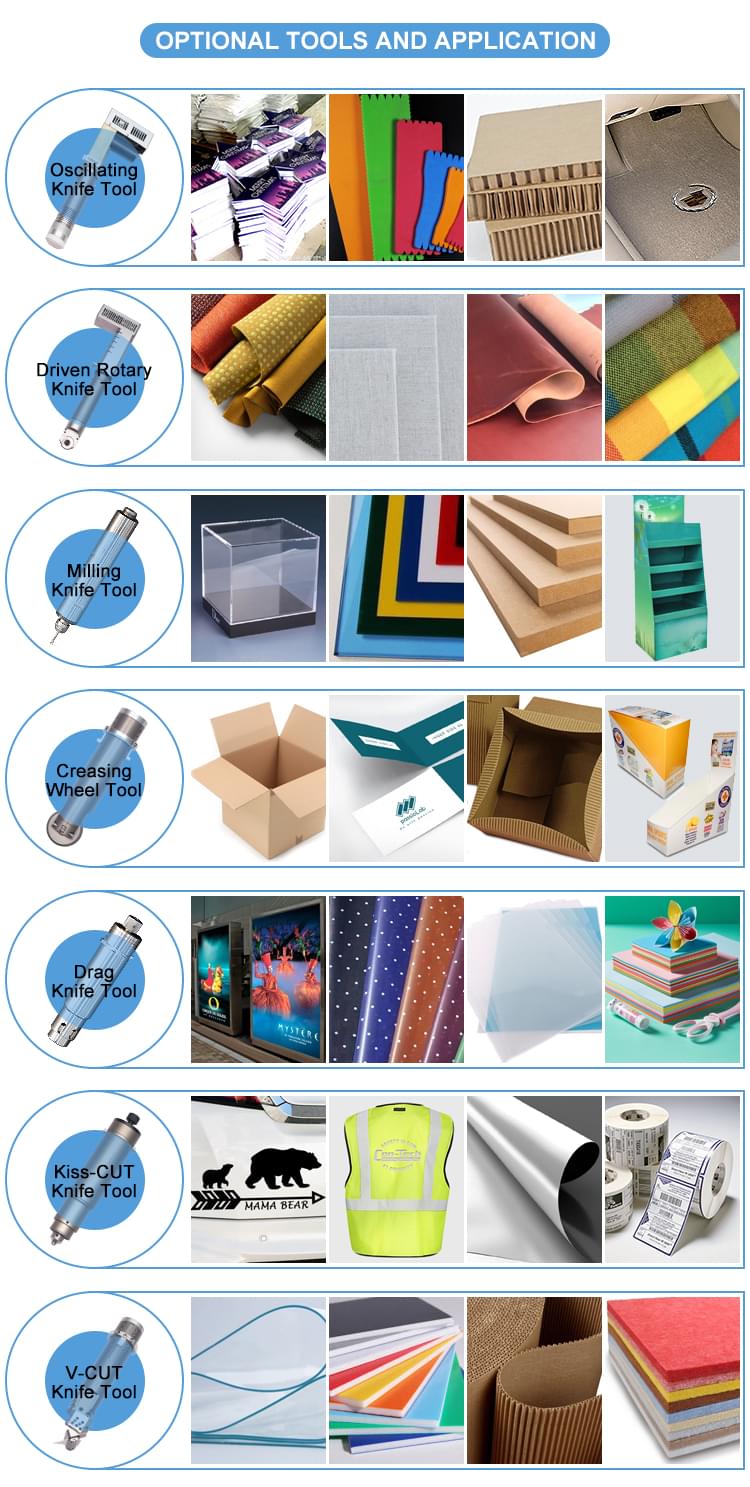

1. Prepreg (carbon fiber prepreg, aramid fiber prepreg), the material is a 1m wide (1.2m wide) 100m long coil, the recommended model is conventional AOL-1625 single-head automatic feeding vibrating knife , the commonly used blade model ZO26a, the price is based on customer requirements, now many customers have various product sizes, and most customers have non-standard customization needs

2. Carbon plate, choose milling cutter, optional model 1325 or 1625 fixed table

3. Carbon felt, choose air knife, blade: JC50

4. Glass fiber cloth, single-layer cutting conventional application, 1.6m wide circular knife automatic feeding platform, commonly used blade Y032a, length according to customer requirements

5. Wind power blade industry application, the current commonly used models are 2150, 2650, 2850, the commonly used blade Y032a and other felt core materials have no fixed size, the equipment models are basically based on customer requirements, or adjacent models are recommended.

Reasons to choose AOL composite cutting machine:

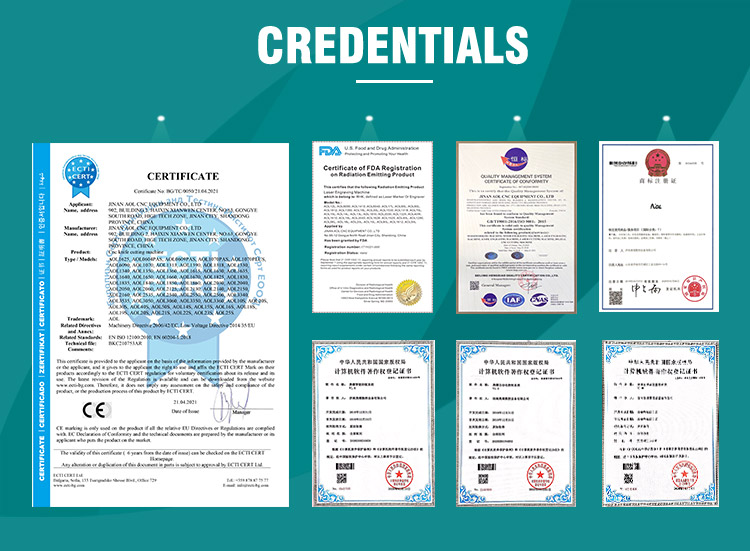

1. High-tech enterprise, AAA-level credit enterprise, AAA-level contract-honoring and honest enterprise

2. There are 58 national R&D patents

3. The whole series of products have passed the IS0 9001 quality system certification

4. All series of electrical products are imported

5. More than 26,000+ global service customers

6. The company promises to enjoy three-year warranty service for all products

7. The company promises that all products can be returned for seven days without any reason

8. The company promises free software upgrades for life

9. The company promises free lifetime technical services

The above are the commonly used materials in aviation composite materials, as well as the machine models and tool recommendations for commonly used materials. If you have any other relevant content about the industry, please contact us, and we will answer you within 24 hours!