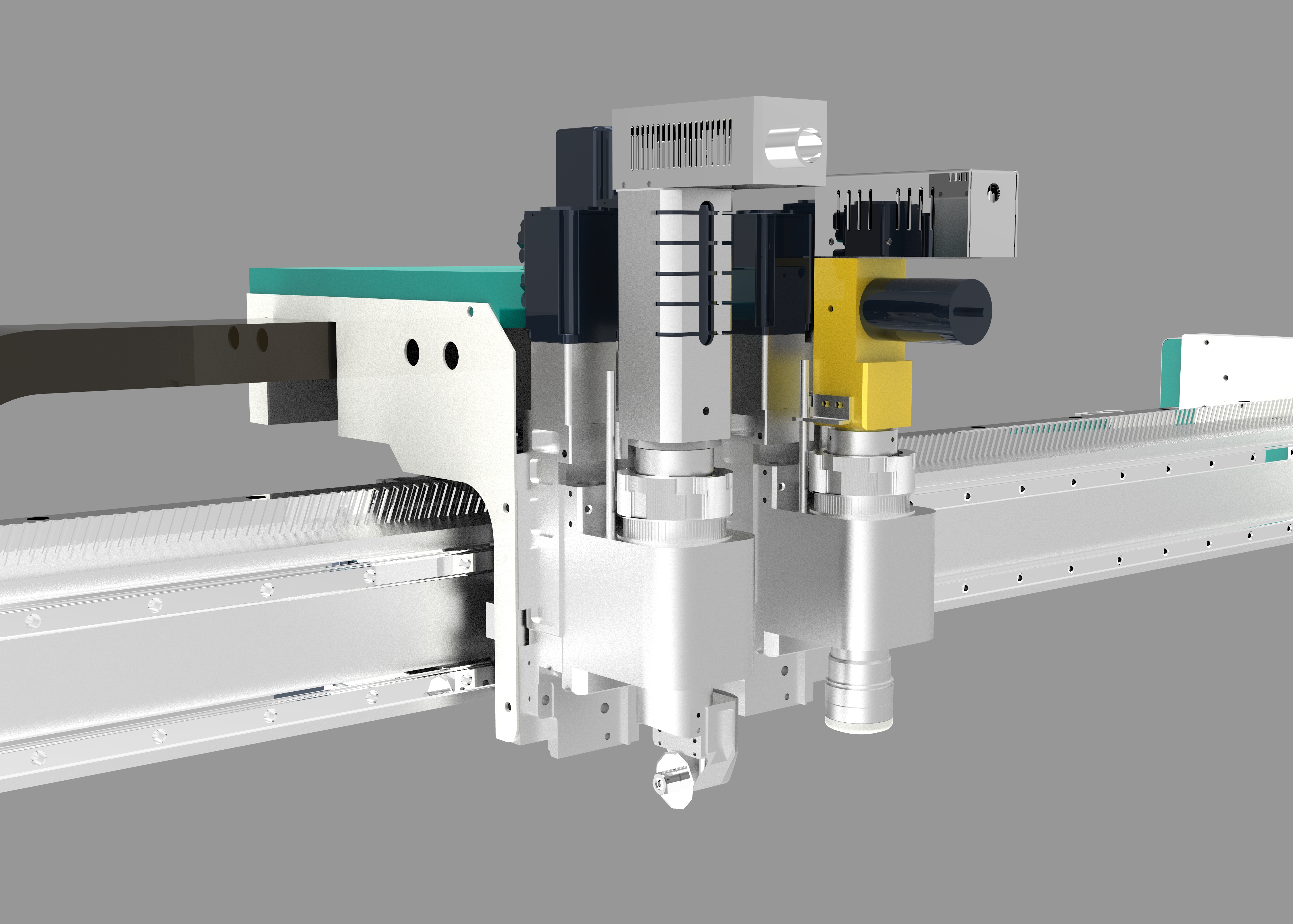

EVA soundproof cotton cutting machine is composed of frame, frame wrapping accessories, beam, cutter bar, electrical appliance and software. The frame of Austrian radium vibration knife adopts integrated welding technology. The frame material adopts 4mm thick square tube at the legs, while the plane support square tube adopts 6mm thick. Moreover, the frame is subject to high temperature heat treatment technology, and the self weight of the equipment is nearly 1.5T, which is stable and undeformed after long-term use.

The software and tool bar departments are independently developed, with fast operation speed and high cutting accuracy. The electrical appliances are all imported. The electrical appliances are tested accessories with long service life and low failure rate. The self-developed AOL cutting system automatic typesetting software and intelligent photo identification software can save more than 15% of materials compared with manual typesetting.

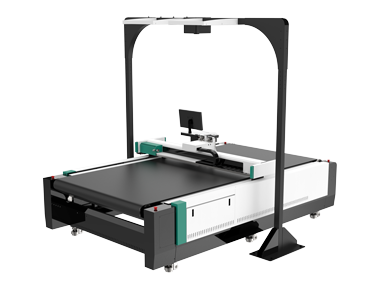

EVA soundproof cotton cutting machine

Cutting process of EVA sound insulation cotton cutter

First, put the material on the worktable or automatic feeding rack. If the coil is placed on the feeding rack, the equipment can realize automatic feeding. If the plate needs to be placed on the worktable manually, the shape to be cut is introduced into the computer, and the cutting system starts automatic typesetting. After typesetting, automatic cutting can be realized.

EVA soundproof cotton cutting machine

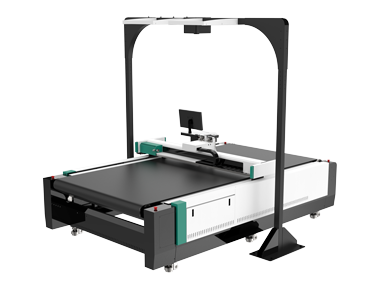

What does EVA sound insulation cotton cutting function bring to manufacturers?

1. Save labor. The equipment integrates automatic feeding, cutting, slotting, punching and blanking. The whole machine can replace 4-6 workers, saving a lot of labor costs every year.

2. High efficiency, the equipment is equipped with imported servo motor, the running speed can reach 2000mm per second, and the processing speed is faster.

3. The error is small. The equipment adopts pulse positioning system, and the cutting accuracy error is ± 0.01mm.

4. Material saving, the equipment has an intelligent typesetting system. Compared with manual typesetting, the material saving is more than 15%, which greatly reduces the production cost of products and improves the competitiveness of products.