Glass fiber cloth is a kind of inorganic non-metallic material with excellent performance. It can be used on ships, vehicles, and building structures. In terms of processing, because the glass fiber cloth is relatively brittle, the general cutting machine is easy to damage the material during the cutting process, and causes a lot of dust. The dust contacts the skin and regrets causing skin allergies. Therefore, find a suitable fiberglass cloth cutting machine whether it is in Work efficiency and health will be better guaranteed.

Two types of cutting machines, vibrating knife and circular knife, are recommended for fiberglass cloth cutting. These two types of equipment have their own advantages and disadvantages. When the circular knife cuts the fabric, because the force on the material is small, the material is cut more completely, and the cutting is not loose. However, when cutting thicker materials, it is recommended to use a vibrating knife cutting machine, because if you continue to use a circular knife to cut, there will be an overcut phenomenon, and the range of this overcut will increase as the thickness of the material increases.

Principle of glass fiber cloth cutting machine:

The fiberglass cloth cutting machine has an automatic feeding system, which can realize automatic feeding by placing the coil on the feeding rack (also multi-layer feeding at the same time), computer typesetting, and data command cutter head to automatically cut various shapes, and the cutting is completed. After that, the material is automatically unloaded, and the rear end is automatically loaded to realize cyclic cutting.

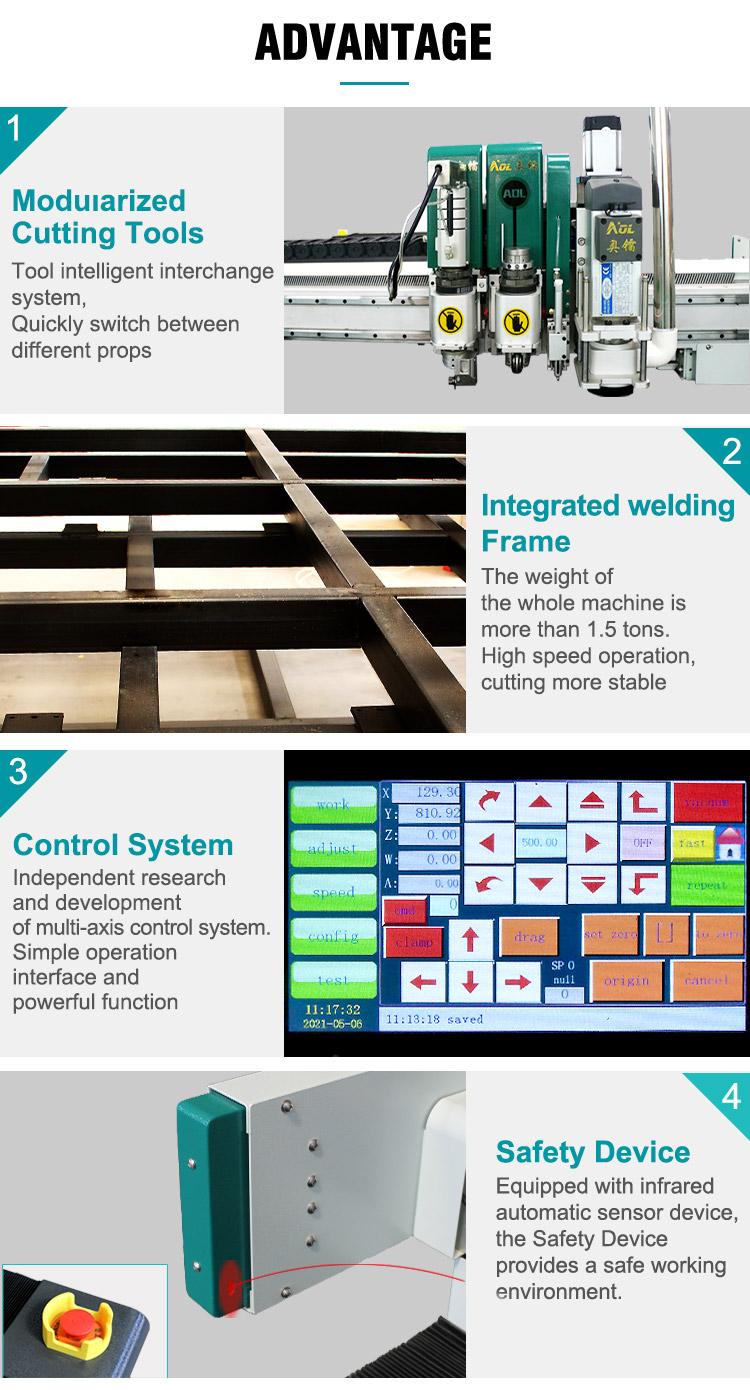

The fiberglass cloth cutting machine adopts the self-developed CAM software to systematically optimize the physical overcutting phenomenon of the tool. The high-performance multi-axis motion control system is equipped with servo motors imported from Japan, which can be cut into any shape according to different product requirements of customers. In order to solve the dust problem, the equipment is equipped with an automatic dust suction function, which can deal with the dust in time when cutting, avoiding the harm of dust to the body.

The built-in super nesting system ensures that there is no waste of materials. According to big data statistics, it can save more than 10% of materials compared with manual labor. The cutting efficiency is high, which can be increased by 3 to 5 times compared with manual labor. It has high precision and high efficiency, and can last for 24 hours. work to maximize production. The operation is simple and the number of required workers is small, which solves the problems of difficult recruitment and high labor costs.

To sum up, the glass fiber cloth cutting machine can comprehensively solve our cutting problems. When the production cost of the product is reduced, the quality of the product is improved, and the competitiveness of the corresponding product is also improved, then there will be more advantages and friends. Competitive market.

If you want to know more about performance issues, please leave a message , we will have a professional staff contact you.