Duct board is the title of "the king of thermal insulation", is a new generation of thermal insulation, fire proof and sound insulation material, it is lightweight, fire proof, meet open fire not burning, smokeless, non-toxic, no drop, temperature enclosure wide (-196 ~ +200℃) etc, widely used in construction, national defense, foreign trade, storage, energy and other fields. They already account for 40 percent of the sound insulation foam used in the U.S. construction industry. With the rapid development of industry 4.0, now the Duct board is not enough for the market, the appearance of AOL NC cutting machine brings a new vitality to many areas, please find the following!

As the title says, can Duct board material be cut with an AOL NC cutter, apparently the answer is yes. We developed a NC cutter for such material, which not only meets multiple types of Duct cuts, but also is very efficient for small lots and multiple orders.

At present, only a small part of the market understands and uses the Duct board CNC cutting machine. Most manufacturers use manual cutting and laser cutting. There is no doubt that labor is not only high in cost but also slow in efficiency, which cannot meet the market demand. As the laser cutting machine is a hot cutting method, it will not only scorch and yellowing materials, but also requires manual secondary processing, resulting in material waste and unnecessary labor costs.

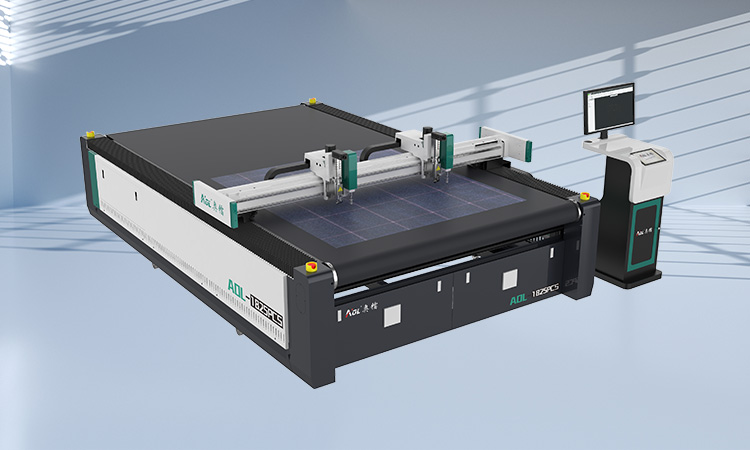

The Duct board CNC cutting machine uses a computer to draw, and after internal data processing, it is transmitted to the machine control card. The control card sends command pulse signals to the servo drive, which drives the servo motor to move to achieve the movement of the machine. At the same time, it sends signals to the cutting cutter to cut raw materials. The blade cutting method is cold cutting, which will not waste materials and does not require secondary processing. The cutting accuracy of our equipment is within ± 0.05mm, and the efficiency is 3-5 times that of manual cutting. In addition, one person can check the operation of multiple machines at the same time. Many businesses have found us and consulted our cutting equipment before this article was published, And several customers have made reservations. What are you waiting for?

The Duat board and Duat board CNC cutting machine are briefly introduced above. Now let's give a detailed explanation of the advantages of our cutting equipment. Watch a video to continue reading!

1. Infrared induction system, 360 ° surround safety, to ensure operator safety.

2. The perfect camera positioning system supports ● or 10 marks to improve work efficiency.

3. Solid aluminum honeycomb platform, with good suction effect, ensures the flatness of the platform, and does not deform after long use.

4. Flexible tool system, compatible with multiple series of tools.

5. Efficient anti dry roll feeding system, which can complete feeding and cutting within 5 seconds; Make the machine realize automatic continuous cutting.

6. Powerful CAD editing and design software, perfectly matched with multiple software; It also supports barcode reading to avoid operators sending wrong cutting files and improve work efficiency.

7. The parameter formulation system can adjust the best cutting parameters according to different materials to ensure the accuracy of each cutting.

8. The overall frame structure, designed by senior engineers in the industry, is simple, stable and easy to install and carry.

9. Precise tool setting system, easy to operate, can accurately control the depth of the knife and extend the use time of the cushion.

10. Scientific and simple wiring system and case circuit design, stable and safe; Equipped with all tool interfaces to support subsequent upgrades; Easy to install and maintain.

Well, we have a comprehensive understanding of the cutting equipment. If you want to know more, please contact us through the following methods or click the link https://www.aolcnc.com/contact/

Email: info@aolcnc.com

Phone: +86-0531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://www.aolcnc.com/