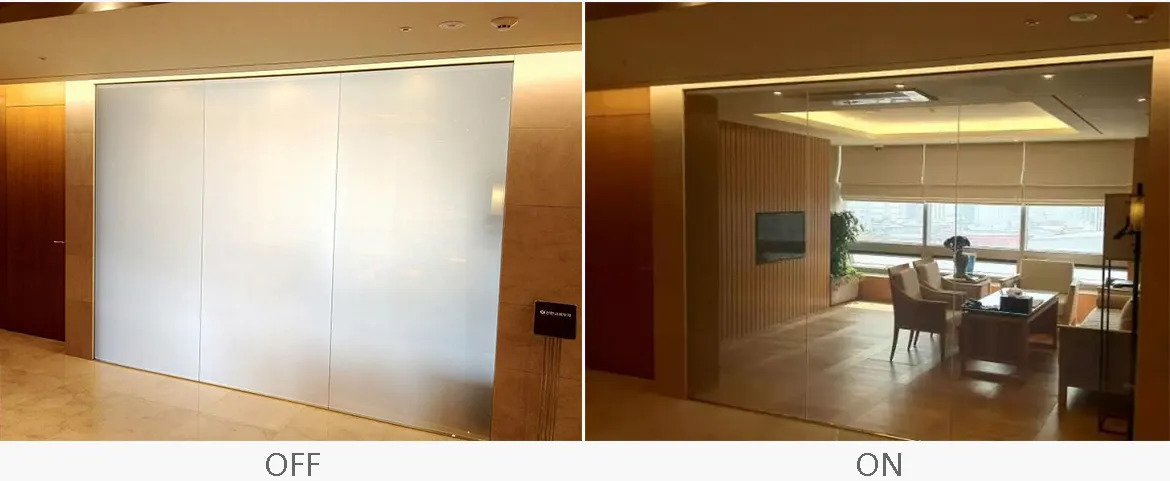

What is a smart PDLC film?

PDLC films consist of micron-scale liquid crystal droplets dispersed in an optically isotropic polymer matrix. By choosing the appropriate combination of liquid crystal and polymer materials, PDLC films can be electrically switched from a light-scattering or opaque "off state" to a non-scattering or transparent "on state." In the "off state", the PDLC film appears milky white due to the refractive index mismatch encountered by the incident light at the liquid crystal/polymer interface.

PDLC materials are now mainly used in the window decoration of offices, conference rooms, etc. in the film industry to ensure a certain degree of privacy.

AOL PDLC film CNC cutting machine can perfectly cut this type of material. Due to the particularity of the film material, there will be no burrs or scorch on the cutting edge after cutting, which will affect the overall function of the PDLC film material.

On the whole, the cold cutting method of the CNC blade cutting machine is suitable for the cutting of PDLC film materials, and the cutting edge is neat and smooth, which will not affect the performance of the product.

Let's learn how the PDLC film CNC cutting machine works through the video below!

Let’s learn about the various parameters of the PDLC film CNC cutting machine:

|

Technical parameters / model |

AOL-1625 |

AOL-1825 |

|

Effective working area |

1600x2500mm |

1800x2500mm |

|

Multi-function tool |

Oscillating knife, round knife, pneumatic knife, drag knife, half cutting knife, press wheel, V-CUT Knife Tool, milling cutter, drawing marker pen, ink cartridge inkjet, cursor positioning, camera positioning edge patrol |

|

| safety devices |

Four corners emergency stop, anti-collision safety device using infrared induction, safe and reliable |

|

| Cutting tool configuration | Oscillating knife or drag knife or round knife | |

|

Cutting speed |

200-1200mm/s |

|

|

Cutting thickness |

1mm-3mm Other thicknesses can be customized according to the material |

|

|

Applicable materials |

It can be used to cut PDLC film materials of a variety of similar materials. Different configurations can be selected for different materials. |

|

|

Material fixing method |

Vacuum partition adsorption |

|

|

Transmission port |

Network port |

|

|

Transmission system |

The X\Y axis is divided into two kinds of rack or belt |

|

|

rated power |

11kw |

|

|

Rated voltage |

380V±10%/220V±10% Optional |

|

|

Control System |

Chinese and English LCD touch screen |

|

|

Operating environment |

Operating environment Temperature 0-40°C Humidity 20%-80%RH |

|

|

Support file format |

AI、PLT、DXF、PDF、 PCE、XML |

|

| Overall size |

3600x2400x1200mm |

3600x2600x1200mm |

| Other configuration | Panasonic servo motor, high precision helical gear reducer, Taiwan Yintai rail, Germany Henryan rack, Omron sensor, Schneider low-voltage appliances, Taiwan Mingwei power supply, Germany cable, 42mm adsorption platform, automatic feeding, Taiwan rail, energy saving fan | |

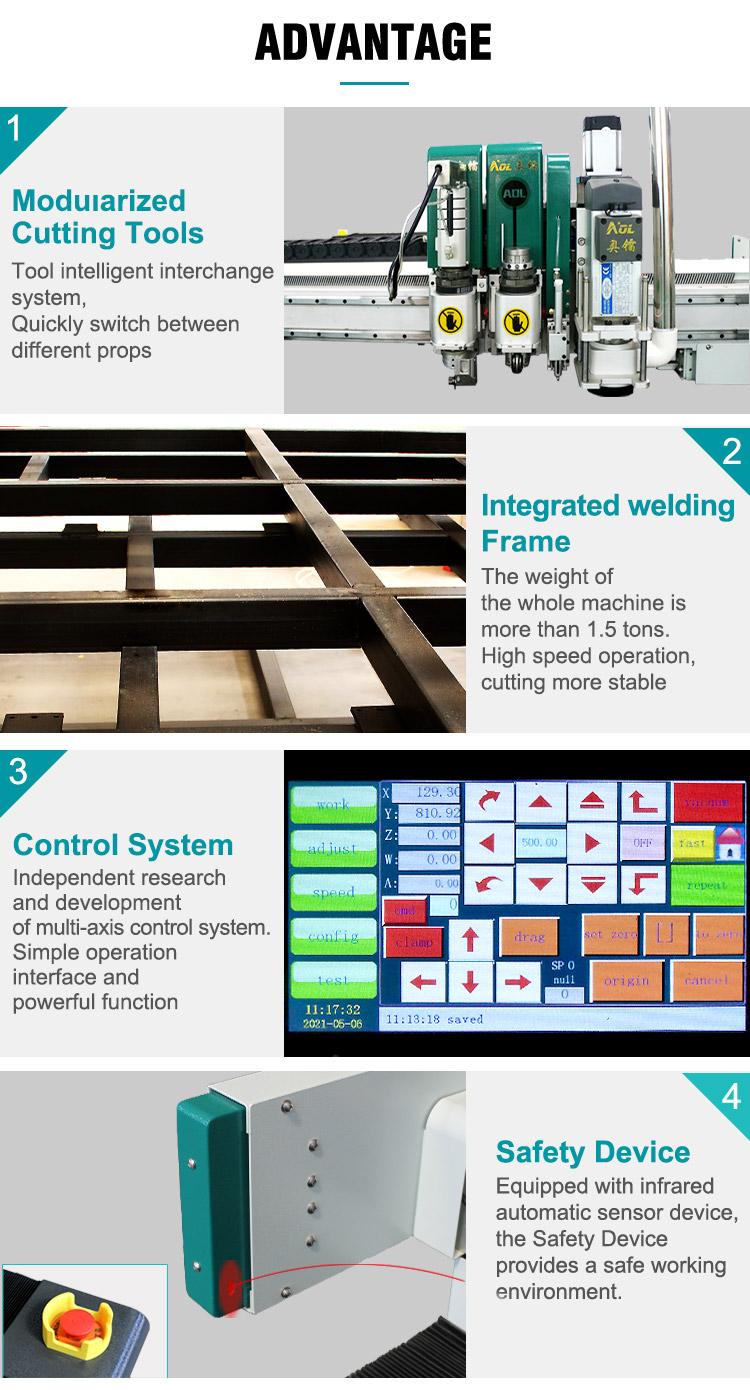

Advantages of AOL PDLC film CNC cutting machine:

1. Not layered

Specially designed and customized knives and blades, the edges do not delaminate after the cut is complete.

2. PDLC film cannot be bent or folded

The flat vacuum cutting table ensures that the PDLC material is flat and firmly fixed on the cutting table. There are no bends or folds in the process.

3. High cutting precision

The intelligent film cutting machine is equipped with Japanese Panasonic servo motor and driver transmission system, and the PDLC film cutting accuracy is within ±0.1mm.

4. Fast cutting speed

Our PDLC smart film knife cutting machine adopts advanced digital control system, and by optimizing the cutting path, the cutting speed can reach 2000mm/s.

5. No cutting limit

Regarding the cutting size or pattern, our CNC knife cutting machine has no limitation, you can cut any size or pattern according to your needs.

6. Cost savings

Automatic nesting software is optional, reducing material waste and saving costs.

7. Safety protection

Infrared induction and emergency stop button, double protection of operator safety.

8. Save labor

The fully automatic CNC PDLC film cutting machine saves labor costs, does not need to be involved in the whole process, and liberates the boss's hands.

If you want to know more about the performance and information of PDLC film cutting machine, please click to leave a message, professionals will contact you, let's find out together! Don't miss this offer.

AOL mainly produces CNC knife cutting machines, cutting plotters, CNC cutting tables, etc. As a high-tech enterprise, we are engaged in the research, manufacture and sales of CNC cutting machines and related products. In addition to cutting film materials, it can also cut advertising packaging, composite materials, carpet industry, clothing textiles, automotive interiors, leather and other flexible material industries!

AOL CNC cutting equipment has 14 years of industry experience. It has provided services for more than 8,000 customers around the world and obtained satisfactory evaluations. We have many long-term and stable customers. We provide personalized industrial material cutting solutions for many customers. If you encounter problems in industrial material cutting, we can provide you with free consultation and consulting services!