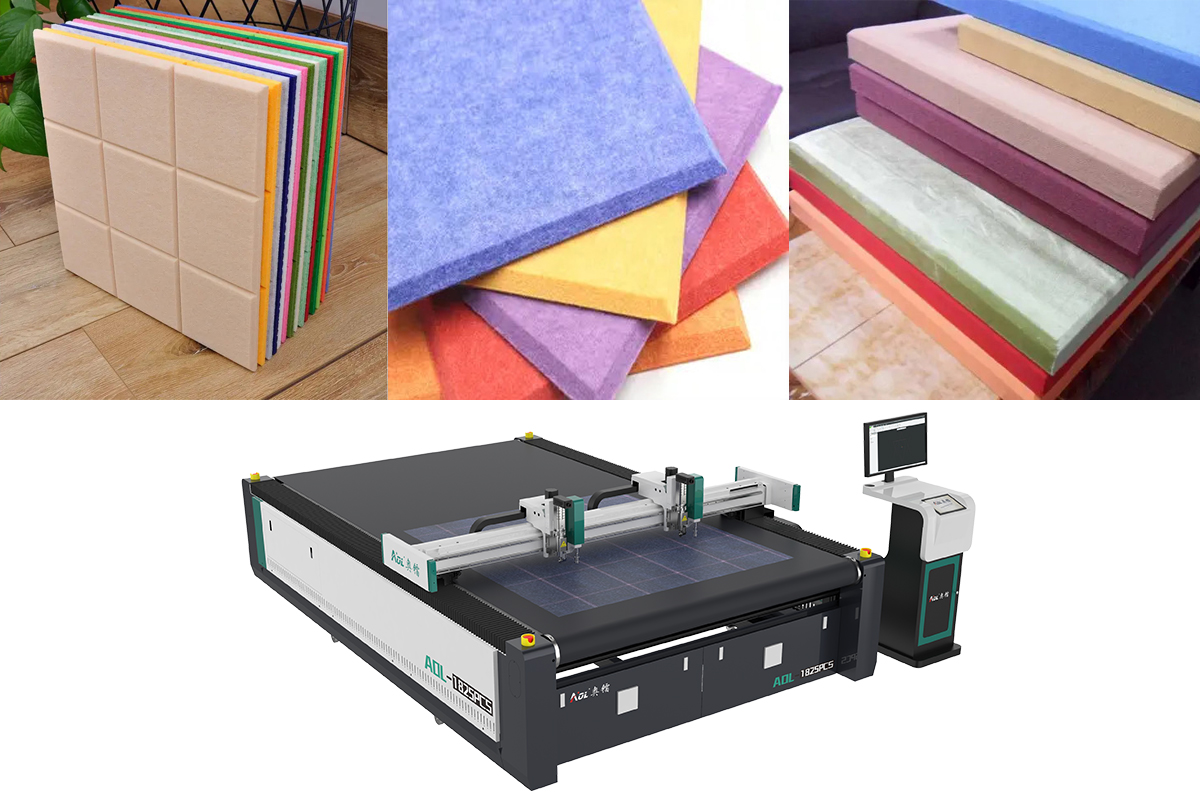

As we all know, acoustic panel are a popular new material in the interior decoration industry, also known as felt pads, which not only play the role of decorative aesthetics, but also play a role in sound insulation. Very important to the decoration industry, so how to make the shape you need, now AOL's CNC Vibrating Knife Cutter will help you.

AOL CNC cutting machine is specially designed for the decoration industry, it can help you cut polyester sound-absorbing panels into the shape you need without burning and yellowing, which can help you make decoration materials in the shortest time. AOL CNC sound insulation board cutting machine can be equipped with vibrating knife tools, kiss cutting tools, rotary tools, V-shaped tools, pneumatic tools, foam tools, etc.

AOL CNC sound insulation board cutting machine can provide faster, more accurate and smarter automation solutions for design proofing, personalized customization, mass production services, etc., compatible with various mainstream design software, equipped with a full set of cutting tools, to deal with different materials (sound board, sound insulation cotton, aluminum foil composite cotton, self-adhesive sound insulation cotton, ceramic fiber cotton, thermal insulation board, XPS, etc.) can meet special-shaped cutting, half-cutting, V-shaped cutting, slotting, drawing, etc., with the precise CCD positioning function, can achieve Automatic positioning and high-precision cutting make cutting more efficient and cost-effective.

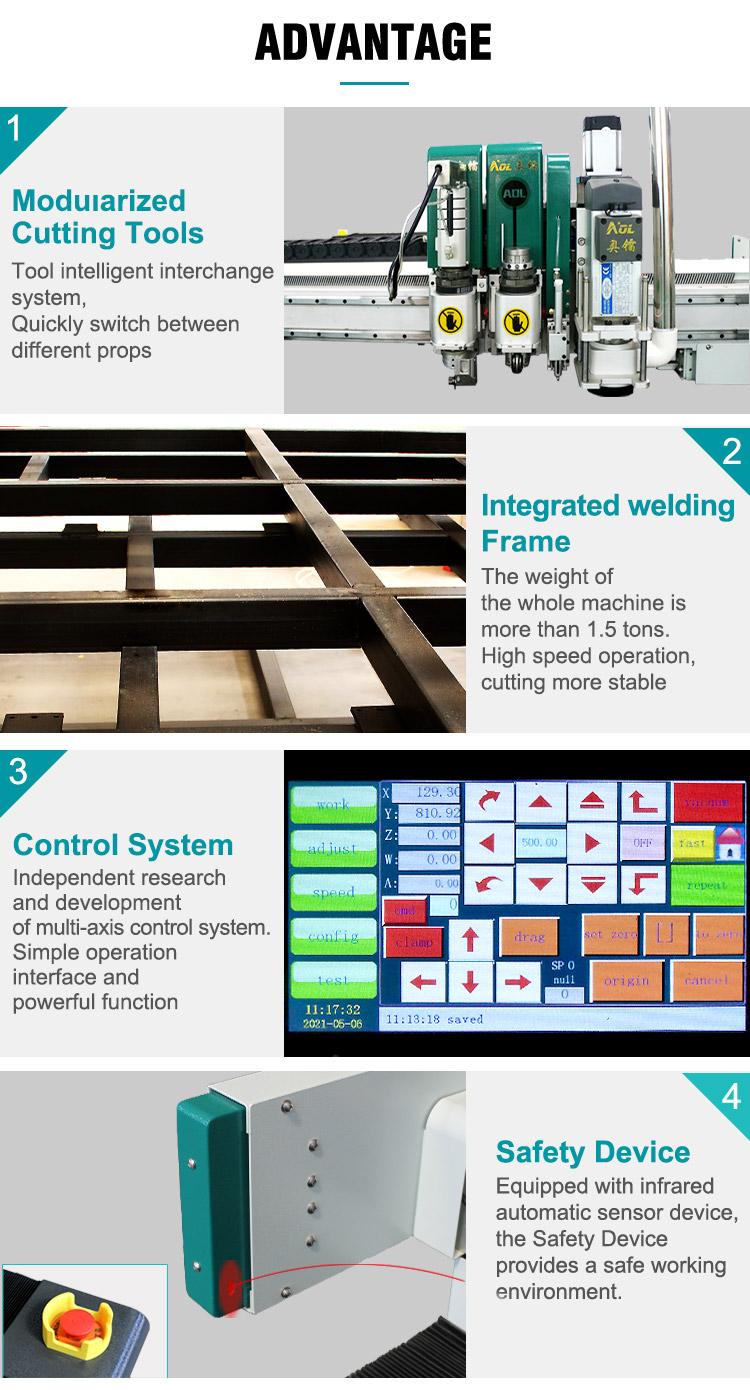

What are the advantages of AOL CNC sound insulation board cutting machine?

1. Using vibrating knife cutting technology, no need to make molds, intelligent cutting has entered the era of digital processing.

2. Multifunctional tool holder design, cutting, beveling, kiss cutting, punching, scribing, one machine completes multiple processes.

3. It can complete the pattern cutting that is difficult, complicated, and cannot be realized by a die-cutting machine.

4. Powerful nesting and counting system, automatic nesting and accurate counting, to achieve high utilization strategy.

5. Effectively identify leather defects, increase output, reduce wastage, and improve the effective utilization of materials.

6. Accurate computer simulation and programmed operation avoid hidden waste and reduce the cost of enterprise materials.

7. AOL CNC blade cutting machine can be equipped with automatic feeding system to realize mechanized cutting.

Why choose AOL CNC sound insulation panel cutting machine?

AOL CNC cutting equipment has been committed to the production and optimization of CNC cutting machines. We have an independent factory, which can complete the design, production, sales, delivery and after-sales service processes. AOL fully automatic computerized cutting system is specially designed for your mass production cutting needs, using a blade cutter for cutting, AOL fully automatic cutting machine provides precise results when told to run, easily producing a range of lines, shapes and arcs.

This high-precision cutting system will consistently and accurately cut any single-layer, low-layer and high-rise cutting job, providing maximum flexibility for virtually all industrial and technical fabrics currently used in the apparel, footwear, luggage, automotive and upholstery industries.

Choosing AOL CNC sound insulation board cutting machine can meet the production goals of small batch, multiple orders and multiple styles, and has a friendly high-definition touch screen man-machine interface, which is simple to operate and easy to learn.

The introduction of AOL CNC sound insulation board cutting machine is here. If you still want to know the content of the equipment or want to know the price, please contact us, and we will answer you in detail as soon as possible!