If you are a manufacturer of various mats, do you encounter the following problems:

1. It is difficult to cut the door mat and tablecloth

2. Low efficiency and high cost of cutting special-shaped doormats and tablecloths

3. Plush floor mats and door mats are seriously damaged

4. High mold cost, short-term production

5. Printed doormats and tablecloths have large cutting errors

6. The cutting efficiency of workers is slow and it is easy to waste materials

...

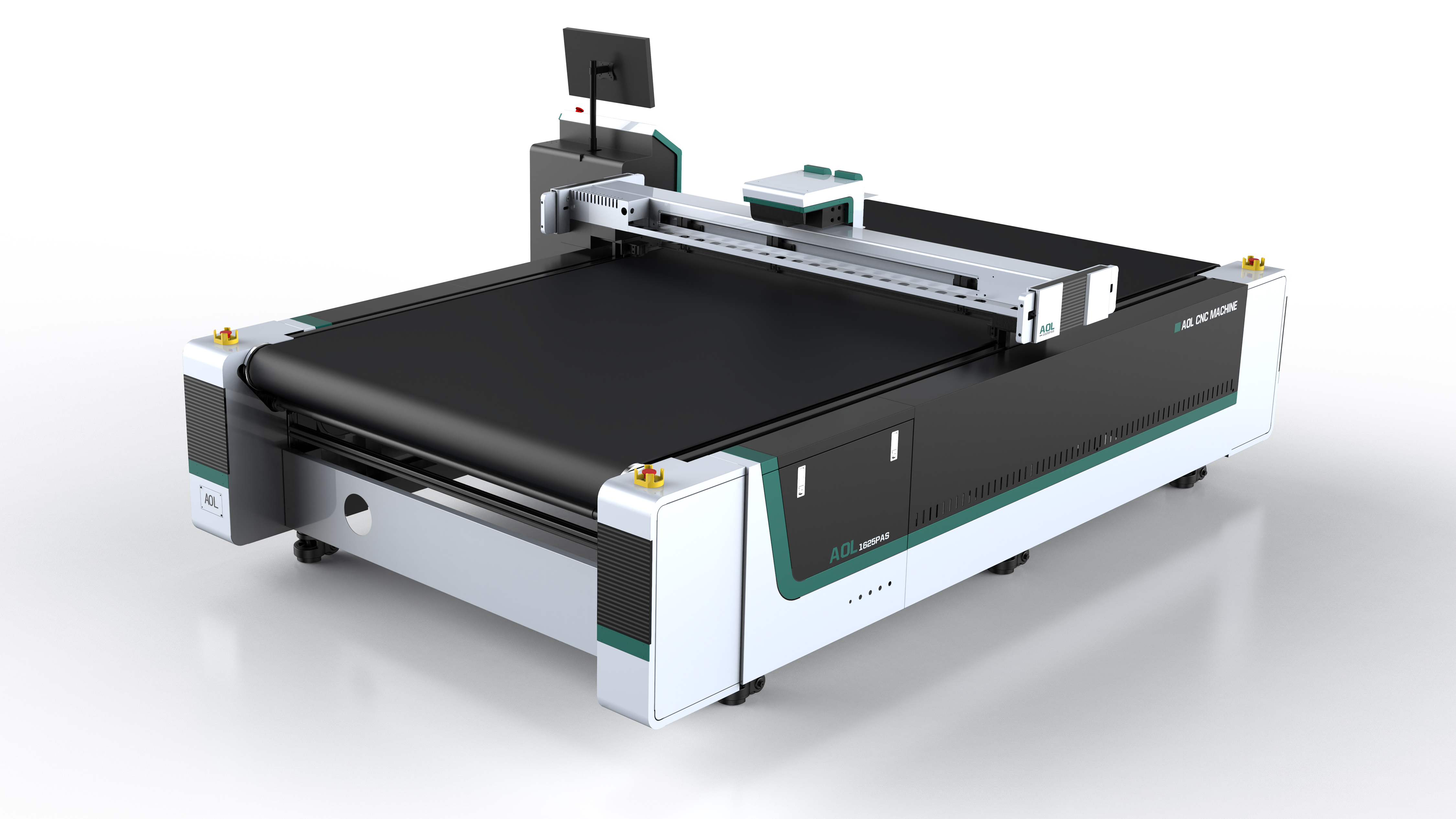

Aiming at this series of cutting problems, here I will introduce the AOL pvc sheet cutting machine for you. pvc sheet cutting machine is cnc cutting machine that can cut doormats and tablecloths in any size and in any shape. It is equipped with a rotary knife tool and an oscillating cutting tool, which can cut 50mm thick sponge compound leather, PVC doormat, tablecloth, carpet, etc. The speed is high and the precision is high, which can reduce the waste of materials caused by manual errors.

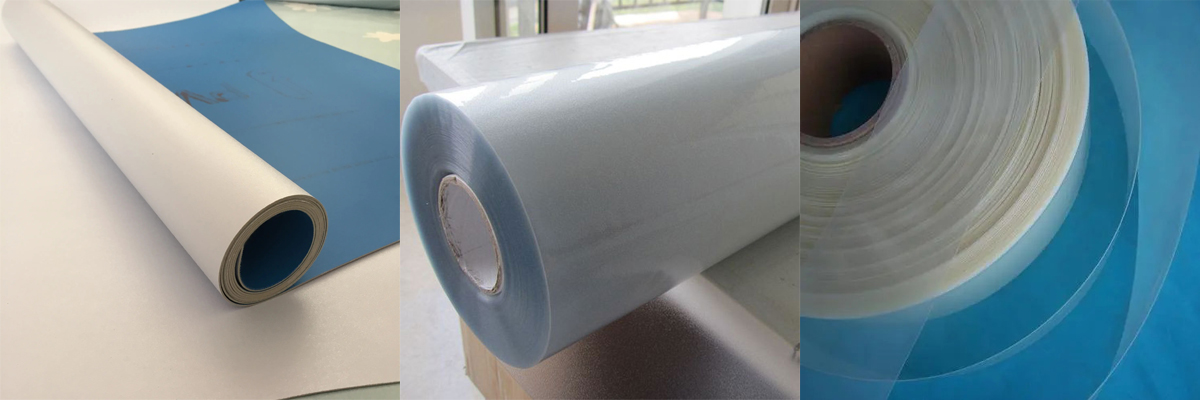

What material is PVC?

The main component of pvc is polyvinyl chloride, which is light yellow, translucent and shiny. From the perspective of transparency, it is better than polyethylene and polypropylene, and inferior to polystyrene. Moreover, PVC can follow the different amounts of additives, and the softness can also be adjusted freely. It is commonly used in plates, pipes, shoe soles, toys, wire outsourcing, doors and windows, stationery, etc.

PVC film is a kind of film coating material formed by film pressing process on PVC material. It is mostly used for surface coating of buildings, furniture, industrial supplies, tools, etc. With the development of the times, PVC film relies on its bright and beautiful appearance. And excellent physical and chemical properties make it quite popular in various industries and widely used.

First of all, the pvc film is vacuum-pressed at high temperature, so it is not easy to fall off after wrapping the material; second, the pvc material is cheaper than other alternatives, reducing production and maintenance costs; finally, the pvc material can be used during the refining process. Toxic substances are extracted, which is safer and more environmentally friendly.

Let's watch a video to understand the cutting process of PVC:

Features of AOL PVC Sheet Cutting Machine:

1. Optimized speed and accuracy

Known for their high speed and precision, high-frequency oscillating knife tools provide efficient cutting capabilities on a wide variety of different materials.

2. Coil feeding rack

Use the coil feeding rack to avoid the coil from falling and achieve a smooth cutting process.

3. Reduce labor costs

It supports the connection of multiple remote computers to realize the separation operation of man and machine, which greatly saves labor.

4. Customized machine size

Customize the right machine size for your production process according to your needs.

5. Files with widely used formats

Strong high compatibility allows easy and flexible connection to widely used DXF, HPGL formats to better simplify and speed up the production process.

6. Automation tools

Advanced tools such as adjustable pressure tools, kiss cutting tools, etc. help to achieve the most stable and fast cutting process.

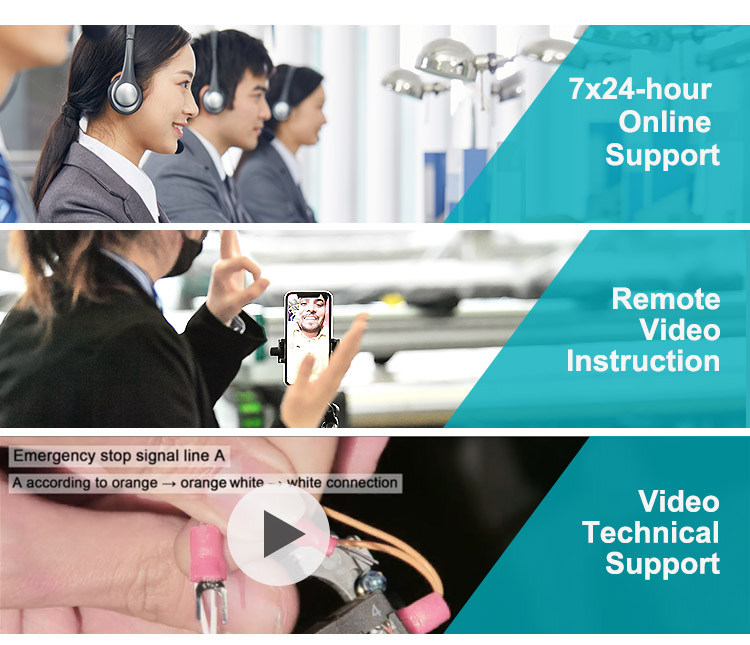

Want to know more, welcome to contact us through the website https://www.aolcnc.com/ or click contact us, you can also contact us through the following ways!