What is an automatic cloth cutting machine?

Cloth cutting machine is a high-speed, high and low layer cutting machine. This automation increases the output of the cutting room. Mass production requires automation to handle large numbers of orders in a smaller space. Automatic cutting machines allow for precise cutting.

Why Garment Manufacturers Need Automatic Cloth Cutting Machines?

Textile companies around the world use electronics and automated cloth cutting machines to speed up production.

Automatic cutting machines are very important for high production textile mills. Because these factories operate faster than hand-cut fabrics. With automatic cloth cutting machines, you can increase productivity and meet the demands of high-capacity factories.

Automatic cutting machines are ideal for cutting large quantities of fabric at one time while offloading excess labor to other units, increasing efficiency and productivity in the workplace.

If you want to improve your fashion design and manufacturing process, the best fabric digital cutting machine can be your right-hand man.

What are the benefits of a cloth cutter?

Cloth cutting machine with high precision and consistency

Human error is common in hand cutting, resulting in wasted fabric and inaccurate cuts. Accurate cutting reduces waste because the fabric is cut to the correct shape the first time. The automatic cloth cutting machine reduces the possibility of product defects due to poor material cutting or human error.

Precise cutting ensures a consistent finished product, which increases customer satisfaction.

Textile cutting machine increases productivity

Factory workers can get tired and hot during their shifts on the factory floor. The repetitive strain injuries that result from operating a manual fabric cutter for hours are unpleasant and can have an indirect impact on cut quality.

Workers don't always do their best work for extended periods of time, and factories must find more efficient solutions to maintain production capacity.

For automatic cutting machines, program files will be designed and created, and optimized for cutting with nesting software. This file will be transferred to the machine controller and command the machine to perform daily tasks.

Garment cutting machine reduces labor costs

Hand cutting is a time-consuming process that requires a large number of workers to do on a large scale. When cutting by hand, workers can only cut one or two layers of fabric at a time. While manual cutting tools do not require a large initial investment, labor costs are quite high for factories targeting high volumes, which is expensive for most high volume garment factories.

As with all cutting machines, the initial labor cost of purchasing an automatic cutting machine is associated with increases, not only with automatic machine purchase and installation time, but also with training and regular maintenance.

Repair costs in the event of a machine failure must also be considered. While this may seem like a huge investment, automatic cutting machines are more cost-effective in the long run.

Not only is automatic cutting more efficient and requires fewer workers, but it also requires less cutting experience from the operator. Due to the high degree of machine automation, the machine can deliver more accurate and less wasted workpieces.

Cloth cutting machine reduces scrap rate

With predictability comes automation. Machines can be programmed to produce products or garment parts in a consistent manner, reducing waste. For example, fabric cutting is more precise when done by machine, as it eliminates the risk of human error associated with manual cutting.

This reduces the likelihood of future product recalls and enables manufacturers to provide customers with consistent quality.

safer working environment

Every year, an estimated 1.4 million workers are injured in garment factories, many of them due to inadequate training of machinery.

Fatigue, misunderstanding, and incorrect machine use can all lead to injury, disfigurement, and even death.

Factory automation reduces the exposure of workers to dangerous moving machinery, thereby reducing the risk of workplace accidents. Manufacturers will benefit greatly as they will no longer face lawsuits from injured parties or their families.

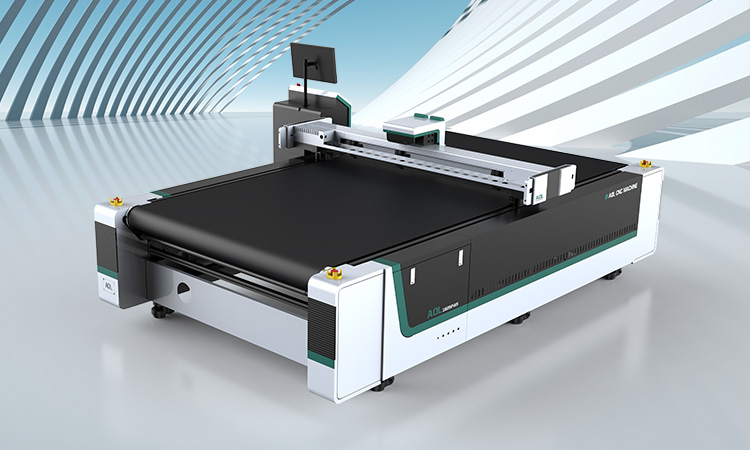

So I think that for garment cutting factories, such a cutting equipment is very much needed. This automatic garment fabric cutting machine can not only cut a single layer but also multiple layers, and can also cut a variety of patterns without making molds, and the table is adsorbed The ability is very strong, and it can guarantee the cutting of multi-layer materials at the same time. If you are looking for CNC cutting equipment or plan to order one, please email info@aolcnc.com or whatsapp: +86 18560162709