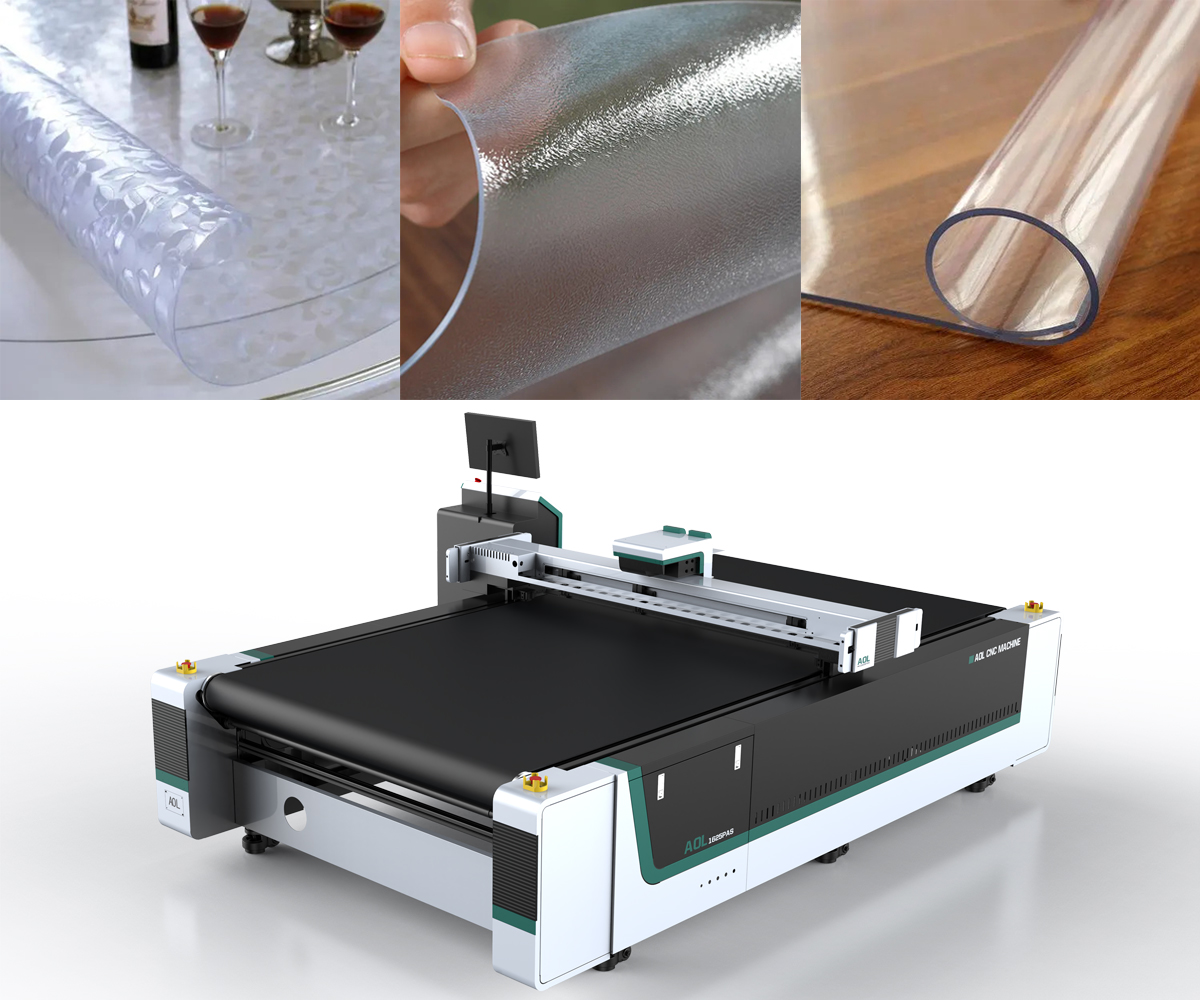

1. What is soft glass?

Soft glass is also called PVC soft crystal board. The essence of the material is PVC board, which is a thermoplastic polymer resin polymerized from vinyl chloride monomer. It is now widely used in industry or home improvement industry.

2. Properties of soft glass

The surface is smooth, no cracks, no air bubbles inside, the overall color of the crystal plate is uniform, it has good heat resistance, cold resistance, aging resistance, heavy pressure resistance, strong acid and strong alkali resistance, transparent material, and good light transmission.

It can be used instead of glass in use, and it has advantages that ordinary glass cannot match: impact resistance, tensile resistance, and good elasticity.

Anti-light, non-deformation, good flexibility and tensile strength.

Soft texture, can be folded or stored in a roll.

Excellent electrical insulation, inert material in chemical properties, not easy to be corroded, non-toxic and tasteless, and can be recycled.

3. Application of soft glass

Thanks to the good performance of soft glass, it is now widely used in various industries.

Industrial products: mats, working platforms for chemical, pharmaceutical, garment manufacturing, food processing and other industries, machine surface desks, etc.

Household items: In household items, soft glass is mainly used as a substitute for glass. It is widely used in dining tables, desks, coffee tables, chopping boards, cabinets and other countertops. It can also be used as heat insulation materials such as cup mats and table mats.

4. How to cut pvc soft glass

The wide application of soft glass is inseparable from the help of cutting equipment, especially special-shaped cutting. The quality of cutting directly determines the level of product competitiveness.

1. Manual cutting

Manual cutting was the initial cutting method for soft glass, but it was replaced by laser machines soon because of its slow speed, poor quality and low precision. Now it is very rare.

2. Laser machine

Laser machine is a qualitative leap in the soft glass cutting industry, which greatly improves the speed and precision of soft glass cutting, and also greatly reduces the cost of soft glass.

However, the laser machine is a thermal cutting method, which not only produces a lot of smoke and odor during the cutting process, but also high temperature thermal processing will destroy the nature of the soft glass cutting surface and damage the material.

3. Oscillating knife cutting machine

The vibrating knife cutting machine is developed on the basis of the laser machine. The speed and cutting accuracy are not inferior to the laser machine. Moreover, the vibrating knife cutting equipment belongs to blade cutting, that is, cold cutting. During the cutting process, it will not be affected by high temperature Destroy the material itself, causing unnecessary waste.

AOL soft glass CNC cutting machines are becoming more and more popular in the soft glass industry due to their ability to quickly and accurately cut soft glass into complex shapes. Equipped with computer numerical control (CNC) systems, these machines precisely cut soft glass while minimizing waste. A CNC system is programmed to cut soft glass according to a specific design, and the machine can be used to cut a variety of shapes, from circles to complex patterns.

Soft glass CNC cutting machines are ideal for creating custom soft glass pieces for a variety of applications. They are often used to make decorative soft glass sheets for windows, doors and other architectural elements. They are also used to make soft glass components for medical and industrial applications.

The Soft Glass CNC Cutting Machine is a versatile tool that can be used to cut a wide variety of materials. It is capable of cutting glass, acrylic and other soft materials. The machine is equipped with an oscillating knife cutting head capable of cutting the material precisely. The cutting head is adjustable to cut soft glass of different thickness.

Soft glass CNC cutting machine is a cost-effective glass cutting solution. It is capable of producing complex shapes with minimal waste and is easy to use. The machine is also relatively quiet, making it ideal for use in a variety of environments.

Soft glass CNC cutting machines are gaining popularity in the glass industry due to their ability to quickly and accurately cut glass into complex shapes. The machines are equipped with a computer numerical control (CNC) system that cuts the glass precisely while minimizing waste. To cut glass to a specific design, the machine can be used to cut a variety of shapes, from circles to complex patterns. Soft glass CNC cutting machines are ideal for creating custom soft glass pieces for a variety of applications.

If you want to know more, please click to contact us or via whatsapp: +86 18560162709