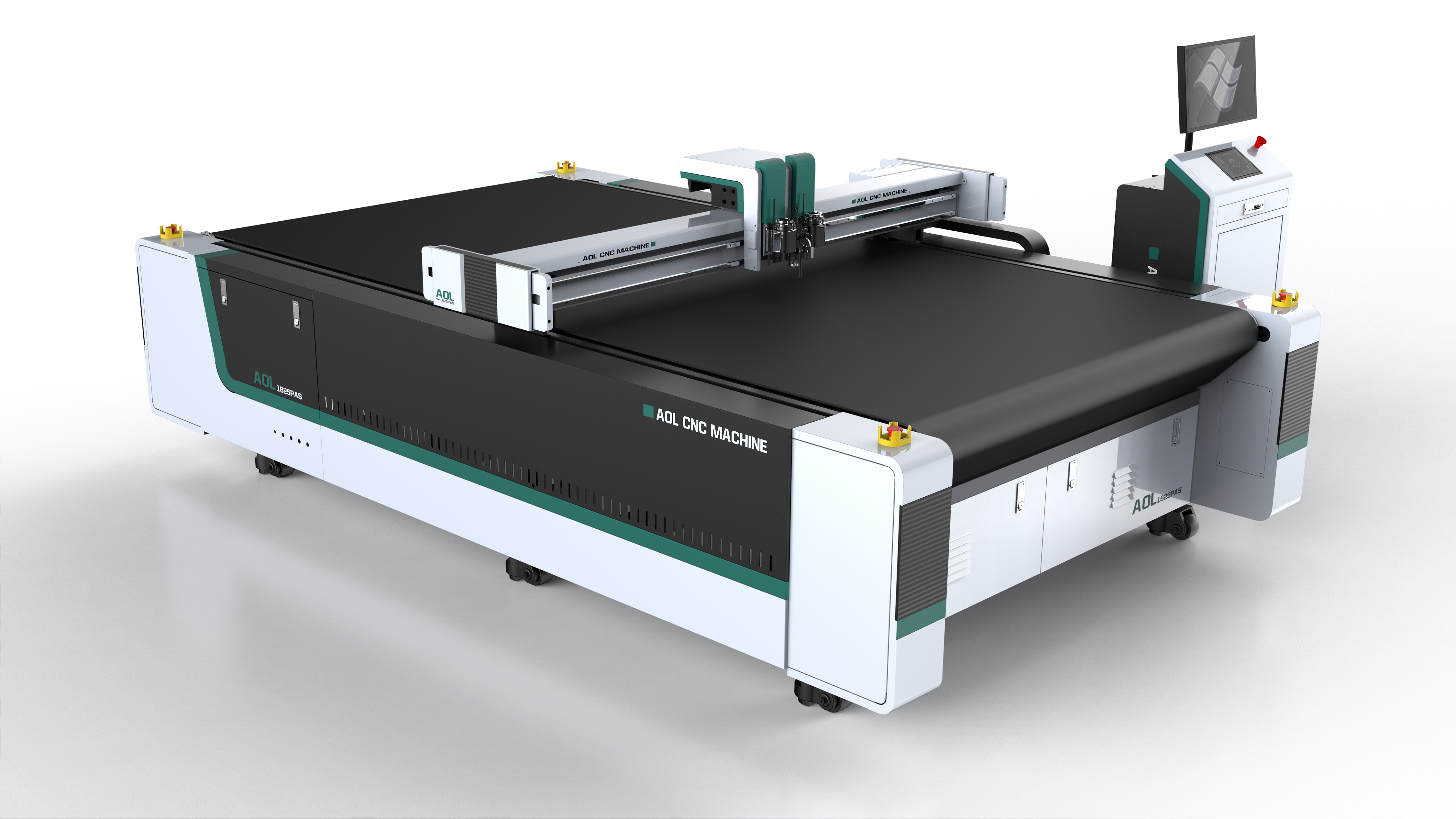

CNC automatic cloth cutting machine is ideal for processing cloth materials as it provides cutting solutions. From single-layer to multi-layer mass production, always maintain the same precision, no need for molds, cut immediately, no need to waste time and high cost to prepare molds. AOL has independently developed single-layer and multi-layer material cutting systems for the fabric industry. With advanced control system and stable bed material, the cutting is not only fast, high precision, but also more stable.

What problems do you have when cutting fabric?

1. Fabric waste caused by fabric laying blocks is required

2. Cloth waste occurs due to manual detection of knives

3. High working load, because the machine remains stationary and the cutting work is done by moving the fabric pieces.

4. Labor wages rise again and again

5. Accident

Why do you need an automatic fabric cutting machine?

Accurate and fast

Cut to size. Set any size in the system and it will cut according to your command. Assuming the cutting speed is 48m/min, please calculate how many pieces can be cut in one piece. The machine does not need to rest and can work 24 hours a day. By calculating the yield, you'll find out how much it will pay off.

high efficiency

The CNC cutting machine can be moved in any direction. The conveyor table can automatically drag the fabric, which is 3-5 times faster than manual work. And can be cut on a large scale.

avoid material damage

With the digital cutting system, you will view the cutting details in the computer. Then the digital cutting machine starts cutting automatically. There will be no human error when cutting.

reduce labor costs

Traditional cloth cutting uses scissors and rotary knives, which require more labor. A CNC cutting machine requires only a maximum of 2 workers to operate the machine and move the material. You can even speed up your production with an automatic loading and unloading system.

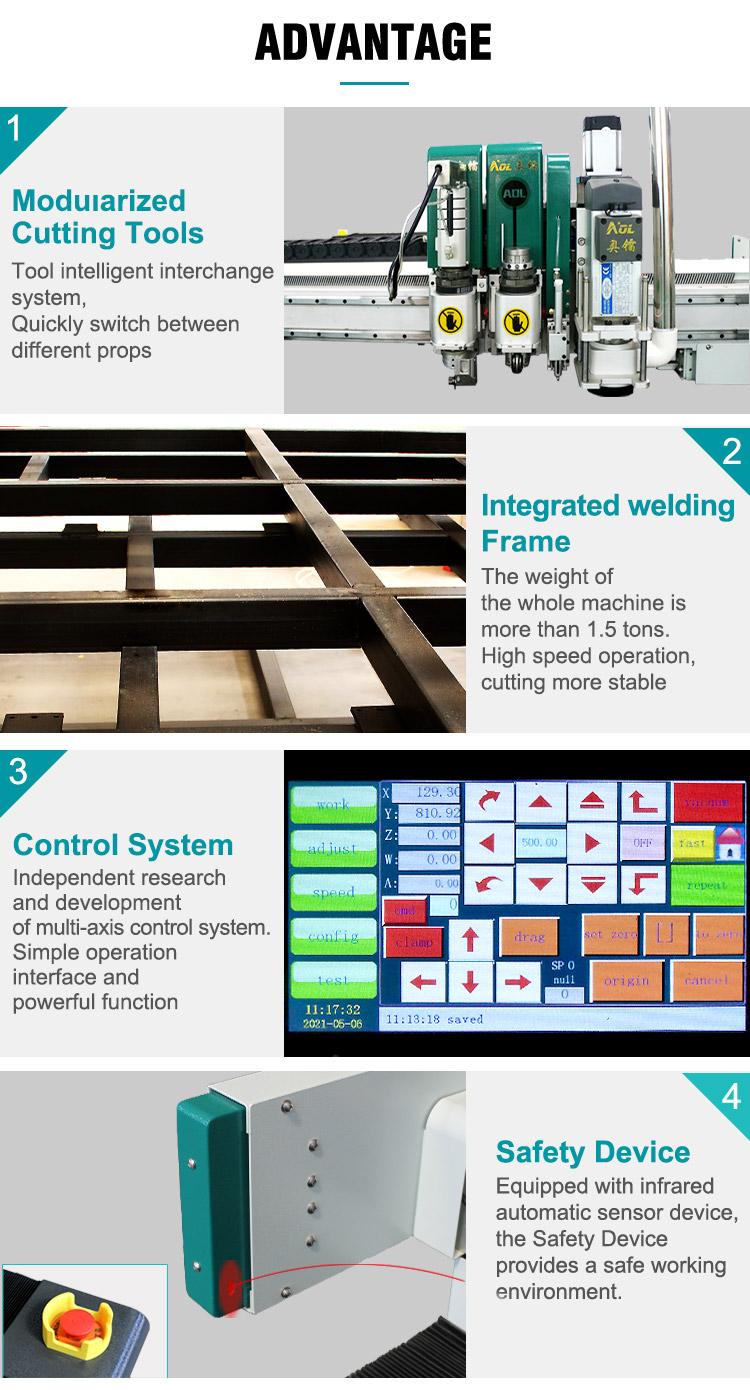

Product advantage description:

Various tool combinations: It can switch to the most suitable tool for cutting according to the material to be cut, improving accuracy and efficiency.

Vacuum adsorption platform: Avoid displacement deviation when cutting soft and lightweight materials, and the material can be adsorbed to the table without moving.

Touch screen panel: color touch control panel, the operation interface is more intuitive, connect to the computer to directly receive data, set cutting depth and cutter head parameters, have a powerful database, and support one-key retrieval.

Honeycomb board platform: It can withstand a lot of pressure without deformation, adjust the height of the table without deviation, greatly improve the operation accuracy, and prolong the service life of the platform.

Precision rack guide rail: Imported rack and guide rails improve work efficiency and machine operation accuracy, avoid cutting errors, and prolong the overall service life of the machine.

Silent towline: scientific and strict wiring, each towline is precisely routed to keep the wiring safe, no static electricity, no bending of the wire, and prolong the service life of the wire.

Precision welded bed: The precision welding of the bed will significantly increase the load-bearing capacity, increase the weight of the bed, maintain the stability of the bed, and increase the accuracy and stability of cutting, especially suitable for fast cutting.

Scientific wiring electrical control cabinet: The wiring is scientific and reasonable, and each wire has a corresponding mark, which is convenient for the maintenance and maintenance of the machine. All electrical components meet the standards of Schneider and top brands.

This is the end of the content. If you want to know or want to inquire about the price and model of the product, you can communicate with us by email info@aolcnc.com or whatsapp: +86 18560162709!