AOL car seat cover cutting system adopts CNC vibrating knife fast cutting technology, which can quickly cut PU/PVC sponge composite materials, leather, cloth and other materials. Used for car seat cover cushion design, pattern making, typesetting, leather cutting, seat cover cutting. The CNC vibrating knife cutting machine has the characteristics of fast, accurate and material saving, which can replace manual cutting and save management and material costs.

AOL CNC technology equipment focuses on sofa furniture, car interiors, car seat cushions and other industry applications. With excellent product performance and after-sales service experience, it helps domestic and foreign customers achieve intelligent cutting and enhance industry competitiveness.

Four advantages of CNC vibrating knife cutting car seat cover:

High speed: It only takes 13 minutes to cut a group of 150 sections of car seat covers (single-layer cutting, or multi-layer cutting of car seat cover materials);

High-tech: Oscillating knife technology for perfect cuts.

High efficiency: The cutting of flexible materials such as leather and cloth can be completed without a die cutter or die-cutting machine, which can save a lot of labor and processing costs.

Non-laser cutting, no burning, no discoloration, no peculiar smell, ultra-high frequency vibration knife cutting technology

The changes brought by CNC vibrating knife cutting machine to the automobile seat cover industry:

AOL car fabric seat cover design pattern cutting system - specially developed for the car seat, car microfiber leather seat cover, luggage, handbag industry, and for furniture, seats, automotive accessories, luggage, handbags and other enterprises. The CNC oscillating cutting system includes six functional modules: data acquisition, design, paper output, proofing, typesetting and cutting.

1. Fully integrate the traditional manual operation mode into efficient and accurate computerized design, realize digital and graphic design, easy to learn and use, rich in functions, powerful, and can effectively improve the efficiency and accuracy of design and production. It also has an automatic nesting function, which can automatically nest the designed paper grids to achieve accurate material calculation and material preparation.

2. AOL automotive fabric seat cover design pattern cutting system - to help you improve the level of informatization and automation management; master the core technology of design patterns; deal with troubles caused by changes in technical personnel; reduce production costs and material waste; improve production in an all-round way management ability.

3. Instead of traditional development, design and proofing, shorten the corresponding development time; meet the customer's production goals of small batches and multiple styles, and form a standardized complete cutting solution.

Which car interior materials are suitable for AOL digital oscillating knife cutting machine?

Applicable materials: leather, PU, microfiber, sandwich cloth, sponge leather, composite materials, felt, PVC, cardboard, paper.

It can be applied to automotive interior and exterior decoration products such as car seat leather covers, cloth covers, sponge covers, steering wheel covers, seat cushions, floor mats, and explosion-proof membranes.

Advantages of oscillating knife cutting solutions:

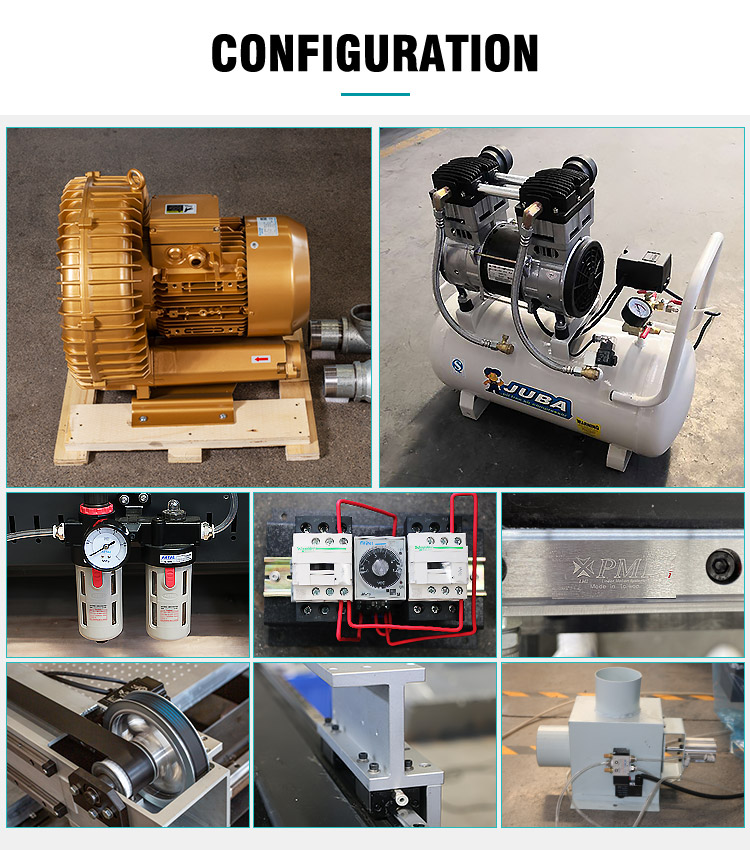

● The cutting machine adopts imported linear guide rails combined with imported racks, and the cutting accuracy fully reaches the zero error of round-trip origin;

● Friendly high-definition touch screen man-machine interface, easy to operate and learn. Standard network data transmission, fast speed, stable and reliable transmission;

●Ultra-high frequency vibrating knife cutting technology, the cutting depth of the knife can be set freely;

● European design standard concept, the motor adopts imported parts;

● Unique safety sensor device, in line with European safety standards;

● Vacuum adsorption technology, the material is firmly fixed on the working surface during the cutting process.

This is the end of our explanation of the car interior cutting machine. Here we only sell cutting machines. If you are interested in cutting equipment, please contact us, and we will answer you in detail as soon as possible!