Carbon fiber processing has transformed multiple industries with its durability and excellent strength-to-weight ratio. Composites such as carbon fiber are versatile and efficient materials that drive tremendous manufacturing innovation. Carbon fiber goes beyond traditional CNC machined materials such as aluminum, steel, wood or glass. It creates high-performance, durable and lightweight components.

Carbon fiber materials can be processed using CNC vibrating knives. The equipment cuts quickly and accurately, providing the best results.

This article discusses carbon fiber properties, carbon fiber material processing, and its applications. We will also provide some tips to help you obtain more suitable results from processing carbon fiber. let's start!

What is carbon fiber and its properties

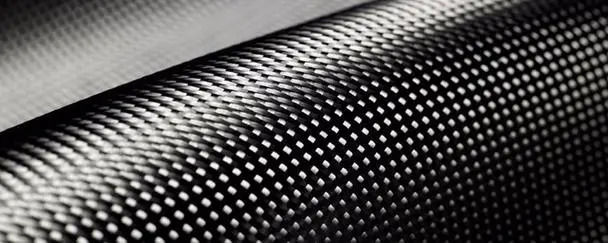

Carbon fibers consist of fiber bundles 5 to 10 microns in diameter that are composed of long, tightly interlocked chains of carbon atoms in the form of microscopic crystals. These fibers are solid and lightweight. Carbon fiber is stronger and stiffer than steel, and lighter than steel.

Carbon plates are known for their incredible strength and durability, making them suitable for a variety of sports, engineering and aerospace industries and many more applications. Carbon fiber is a lightweight composite material with excellent toughness, hardness, wear resistance and corrosion resistance.

Applications of carbon fiber machined parts

Carbon fiber is a lightweight material suitable for a wide range of applications due to its excellent mechanical properties, thermal conductivity and low coefficient of thermal expansion. Carbon fiber has a wide range of applications in various industries. Here are some of them:

aerospace industry

The aerospace industry is one of the industries with the highest application volume of carbon fiber. It was one of the first industries to adopt carbon fiber as an ideal alternative to titanium and aluminum in specific components.

Carbon fiber aircraft parts manufactured in 1940. Many aircraft components are made from carbon fiber-reinforced polymers, which are often preferred over metals when developing aircraft because they have an excellent strength-to-weight ratio and have a longer service life. It significantly reduces the weight of aircraft components.

Aerospace components such as gliders, jets or helicopters rely on carbon fiber to improve performance. In addition, the weight-saving properties of carbon fiber help significantly reduce aircraft fuel consumption.

Sports industry

Some professional athletes use pieces of carbon fiber in their sports gear—tennis rackets, bicycle wheels, helmets, bicycle frames, archery bows, hockey sticks, golf clubs, and more.

However, clothing and protective gear (such as unique leg and arm protectors) are made from carbon fiber. Additionally, in racing or extreme sports, athletes use helmets and strong, lightweight shoes made of carbon fiber.

Carbon fiber is an ideal material for sports equipment. It has huge advantages due to its high strength and light weight. It is much lighter than plastic and wood, allowing athletes to use their sports equipment with ease. As a result, athletes can run faster, jump higher, and swim further.

Automobile industry

Carbon fiber has excellent strength and durability, making it a versatile material in the automotive sector. Therefore, car manufacturers use carbon fiber to make vehicle frames and some other components.

Additionally, carbon fiber's superior strength-to-weight ratio helps influence the automotive industry in the creation of faster cars.

Carbon fiber enables automakers to remove unnecessary metal components from a vehicle's structure and replace them with lightweight carbon fiber. It helps reduce vehicle manufacturing costs while reducing fuel consumption and CO2 emissions.

Electronic products industry

The electronics industry has benefited greatly from the vast advantages of carbon fiber. Its weight-saving properties are qualities most customers are looking for. Likewise, it has a higher natural frequency and maintains dimensional tolerances compared to metal and plastic housings.

The thermal coefficient (CTE) of carbon fiber is equal to Invar. As a result, it significantly reduces thermal issues for sensors, sensitive electronics, mirrors and lasers. In addition to its excellent mechanical properties, carbon fiber is also used as a functional material due to its excellent electrical conductivity and non-magnetic properties. It also has important applications in the electronics industry.

Electronic shielding devices made of carbon fiber have good electromagnetic wave absorption capabilities. The composite of carbon fiber and polymer forms a filled composite material, which not only has a good shielding effect, but also greatly improves the mechanical properties of the shell material.

How to process carbon fiber?

Here we recommend using a CNC cutting machine to process and cut carbon fiber. The processing of carbon fiber composites should be carried out with the highest precision. Processing carbon fiber is expensive. Therefore, incorrect cuts should be avoided or minimized at all costs.

This equipment uses computer graphics, and transmits it to the machine control card through internal data processing. The control card then sends command pulse signals to the servo drive. The drive drives the servo motor to move the machine, and at the same time sends signals to the cutting tool to control the movement of the machine. Raw material undergoes cutting action.

If carbon fiber is used in large quantities, wear a respirator with an appropriate filter.

Keep cutting tools sharp for cleaner cuts.

Practice on scrap pieces to get a feel for working with carbon fiber before cutting the final parts.

Carbon fiber is a compound with a unique appearance and superior performance that helps reduce component weight while maintaining strength. A CNC cutting machine is ideal for precision machining of carbon fiber panels as it is more efficient than hand tools. Undesirable results and material waste can also be avoided.

If you want to know more, please contact us via email info@aolcnc.com or whatsapp +86 18560162709 !