EVA foam has excellent chemical properties, is biodegradable and does not pose a hazard to the environment when discarded or burned. Lightweight and highly flexible, chemically resistant and elastic, it can be used as packaging films, gaskets, medical devices, hot melt adhesives, cable insulation, and more.

Among the die-cut parts we process, we often encounter EVA foam cutting. The common thickness is between 1-2mm, but it may reach 5mm thickness. Regarding the processing of this foam, when cutting In the process of processing operations, there will definitely be many problems of one kind or another. So the problems we often encounter are mainly manifested in the following three points:

1. The beveled edge is easy to appear in the process of foam die-cutting (the beveled edge of the circular knife die-cutting is larger);

2. Debris and dust are easily generated during the punching process of these thick foams;

3. For some porous products, it is difficult to discharge waste (the hole diameter is too small, the thickness of the foam is large, and the waste discharge is not easy to complete);

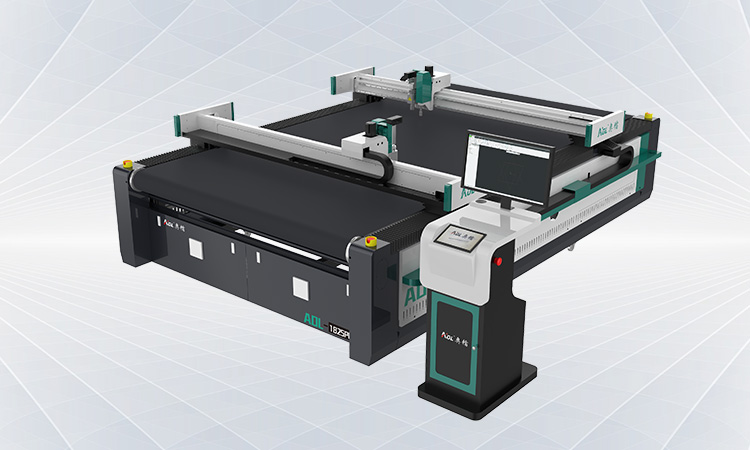

The following introduces an eva foam die cutting machine, which can solve most of the problems and become an indispensable product assistant in the packaging industry.

The cutting thickness of AOL EVA foam cutting machine is about 1-10cm (depending on the material). It is cut with a blade without making a lot of molds, and the cutting process will not produce beveled edges. There is no debris in cutting, and for holes with small diameters It can be equipped with a punching knife for punching and shearing, and the whole process of cutting is environmentally friendly and pollution-free.

Effectively solve the three major problems encountered in the cutting process: "beveled edges are easy to appear in the punching process", "scraps are easily generated in the punching process" and "hole-shaped products are difficult to punch and shear".

At the same time, the entire machine bed of AOL EVA foam vibrating knife cutting machine is equipped with a safety protection system, which can avoid some accidental injuries during the punching and shearing process of the punching machine. It is worth mentioning that an AOL EVA foam cutting machine replaces 4-6 laborers, which greatly improves the cutting efficiency. With the addition of the super nesting software, it can save more than 15% of materials, and truly make EVA manufacturers produce more efficiently, Product quality clearance is double satisfaction.

In addition, our cutting machine can also achieve maximum utilization, not only cutting eva foam, but also suitable for the following industries:

1. Packaging industry: corrugated cardboard, honeycomb cardboard, kraft paper and other packaging boxes (cutting, creasing, dotted line cutting, scribing)

2. Advertising industry: stickers, labels, PP paper, flags, inkjet cloth, light boxes, KT boards

3. Car interior industry: car interior dimensions of various models, as well as leather and artificial leather

Leather and other materials (with multi-model database)

4. Composite materials: EVA, EPE, PVC, soft glass, fiber products (glass fiber, carbon fiber, etc.), thermal insulation cotton, sound insulation board, rubber, etc.)

5. Leather industry: leather materials, artificial leather materials, composite leather materials, etc. (cutting, scribing)

6. Gasket industry: gaskets of various materials (asbestos, non-asbestos, rubber), PTFE (special-shaped, small area cutting)

7. Carpet industry: all kinds of carpets, silk circle carpets, diatom mud carpets and other carpets in various environments (standard or special-shaped cutting)

Of course, many people will also ask a lot of questions, why choose AOL CNC cutting equipment? We at AOL are an industry leading brand with 14 years of industry experience. We have served more than 8,000 customers around the world and received satisfactory reviews. We have many long-term and stable cooperation customers. We provide personalized industry material cutting solutions for many customers.

We have an independent factory, which can completely realize the process of design, production, sales, delivery and after-sales service, and perfectly realize the cutting shape you want. The whole process is automated, no manual intervention is required, and high-efficiency and high-precision servo motors are used. More accurate realization of intelligent cutting. If you have problems with cutting materials in the industry, we can provide you with free consultation and consulting services! Click for inqueries!

For more information, please consult:

Email: info@aolcnc.com

Phone: +86-0531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://www.aolcnc.com/