AOL Composite Cutting Machines meet the needs of customers in expanding market segments such as industrial fabrics and composites.

Manual cutting challenge:

You can use more expensive composite materials for more efficient results

When working with advanced materials, unreliable cutting methods can have a devastating effect on production and profits.

AOL digital cutters are ideal for cutting carbon fiber, fiberglass and aramid in dry and pre-formed form, with or without peel ply.

Difficult materials make automated fabric cutting more essential than ever

While higher levels of automation aren't always easy to achieve, if you have to cut or wet a large amount of material, it's time to take a second look at automated cutting techniques.

The latest technology can drastically reduce scrap, eliminate labor costs and improve quality.

What composite materials can AOL CNC cutting equipment cut?

Aerospace, wind energy and automotive manufacturers use AOL flexible cutting machines.

AOL's application specialists have extensive experience cutting prepreg and dry composite materials, including but not limited to:

carbon fiber

glass fiber

Aramid fiber

engineering fabric

Non-woven core material

Advantages of CNC cutting machine for composite materials:

Material cost can be reduced by 30%

Increased Productivity and Ratio in Composite Fabric Cutting

Capable of reducing labor and eliminating the need for skilled cutters.

Maximize footprint

Advanced integrated data sharing saves money and time.

The cutting process can be easily analyzed and improved using automatic indicators.

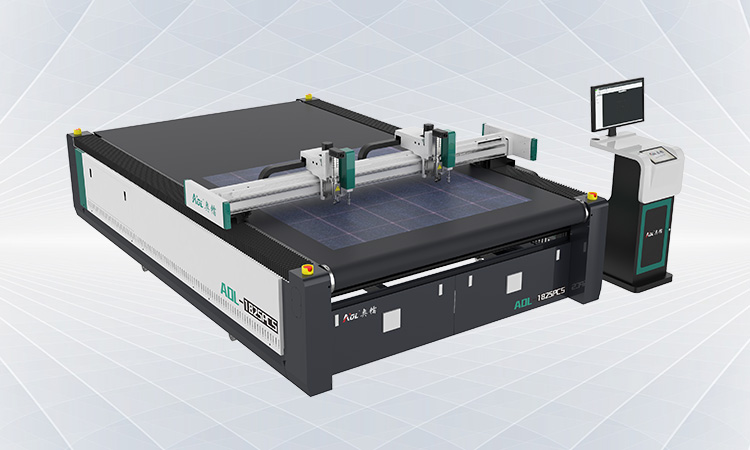

The composite fabric cutting machine trolley moves along the crossbar along the width of the cutting area, while the crossbar moves along its length. These movements enable the composite cutting device to traverse the cutting area and are precisely controlled by the control system. Modern cutting machines have a vacuum system that holds the material in place and increases cutting precision.

You may ask, do I need a digital cutter? If your company has the following conditions, please consider purchasing a CNC cutting machine.

Manually cut expensive composite materials such as carbon fiber and fiberglass.

many materials and patterns

Bottleneck in cutting area

Human error and poor nesting practices can lead to high scrap rates.

Digital Cutting Technology Reduces Costs and Increases Flexibility

Digital cutting of composite reinforcements and other technical textiles can be done faster and more accurately, drastically reducing material and labor costs.

Improved Material Utilization - Automatic cutting machines are more precise and repeatable than manual cutting, reducing errors and waste. Easy-to-use nesting software automatically arranges template shapes in a material-saving manner for each size of material being cut.

Flexibility is the result of efficiency - automatic cutting increases throughput. In some cases, cutting can be done close to the layup, or in some cases simultaneously.

Lower Labor Costs – Machine cutting is faster than manual cutting, even with static table machines where the operator manually positions the composite material for cutting.

What are the characteristics of composite material CNC cutting machine?

advanced software

Digitally stored cutting pattern tables are available to guide the cutting path and conveyor feed for each workpiece.

nested function

Automatically arrange template shapes according to material efficient arrangement.

Conveyor system

The conveyor system is also computer controlled and can be used for continuous feeding. This allows for cutting large or multiple pieces without interruption.

By combining precise cutting and nesting software, automatic cutting can create patterns in the most efficient way, thereby reducing material consumption significantly.

material compaction

The operator simply places the material on the table and activates the vacuum. The system automatically assigns the material.

camera virtual system

Pattern matching can be done in an automated system by projecting an image of a mark onto the fabric or by creating an image of the fabric pattern on a screen.

The components of computer cutting machine:

The following are the main components of a digital cutting machine.

CNC Machine Tool Hardware

Workbench with conveyor belt

blower system

Smart Knife - This cutting machine is equipped with a computer controlled knife.

Keyboard and Display

AOL intelligent blade cutting machine has high precision and high efficiency. Our professional after-sales service can provide automatic cutting solutions for various industries.

For more information, please consult:

Email: info@aolcnc.com

Phone: +86-0531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://www.aolcnc.com/