Composites have become the darling of modern engineering, offering the perfect blend of strength, durability and lightweight properties. However, the unique composition of these materials creates many challenges during processing, especially in the cutting area.

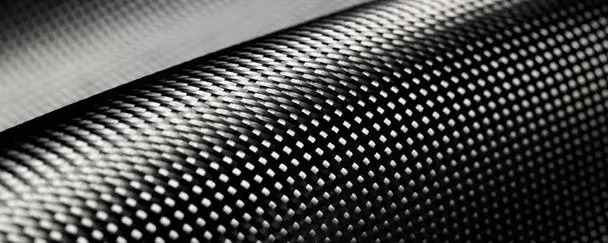

What are composite materials?

Composite materials refer to materials that are composed of two or more different substances combined in different ways. It can bring into play the advantages of various materials, overcome the shortcomings of a single material, and expand the application range of materials. Although composite materials have obvious advantages compared with single materials, they are difficult to cut and suffer from high material loss. This requires precise production processes to minimize losses.

Composites are designed by combining two or more different materials to create new materials with enhanced properties. Typically, reinforcing fibers such as carbon or glass are embedded in a matrix material such as epoxy resin. This combination provides superior strength, reduced weight and enhanced corrosion resistance compared to traditional materials.

What are the difficulties in composite material processing?

1. Manual processing has large errors and low efficiency

2. Material prices are high and manual cutting costs are wasteful.

3. Manual unloading efficiency is low

4. The material has high hardness and requires high processing equipment.

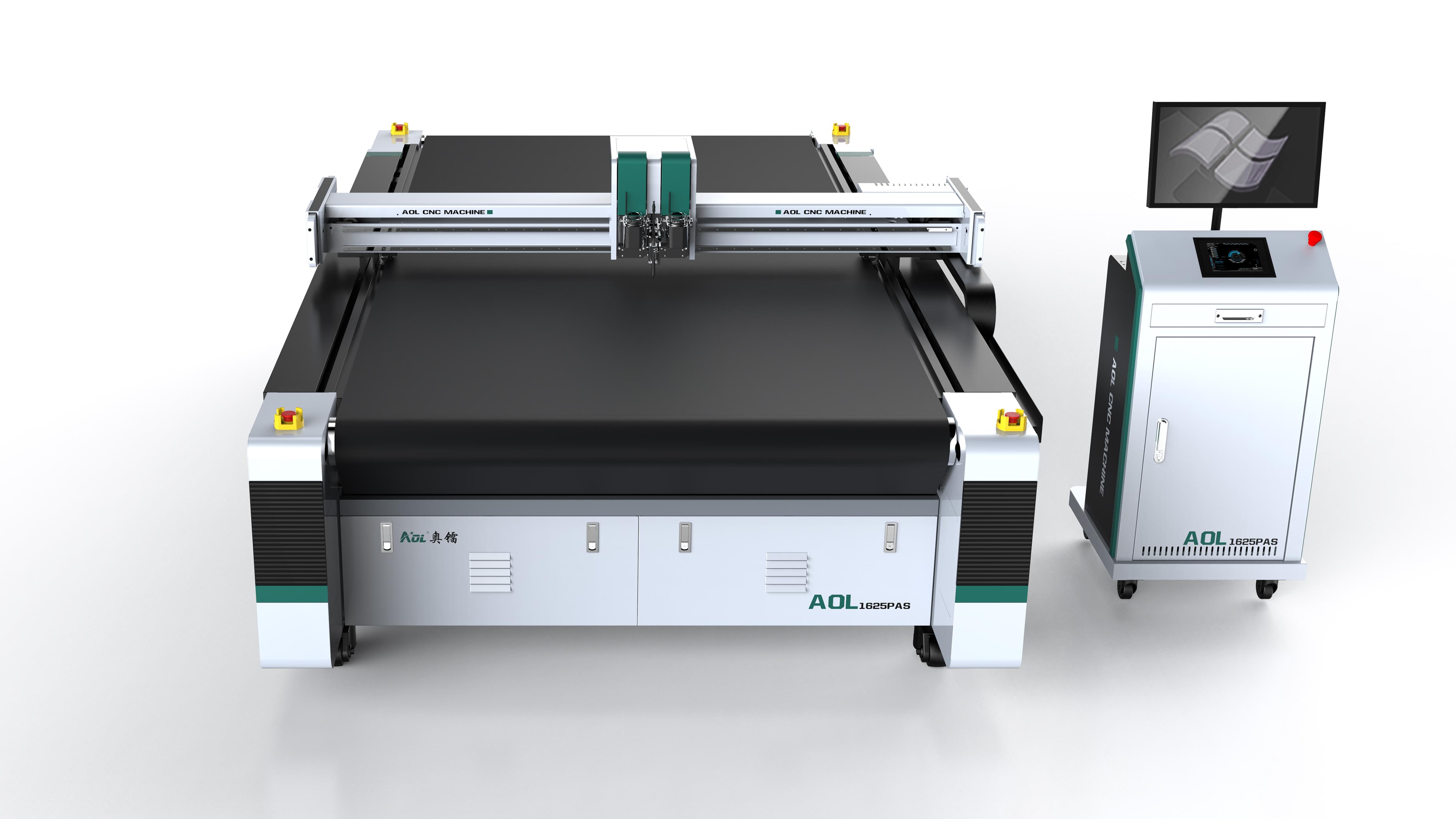

AOL CNC composite material intelligent cutting system:

Details and strength coexist

Diversified cutting modules can be freely combined as needed to meet the cutting needs of different materials in different industries.

Upgrade circuit layout

Newly upgraded circuit layout makes operation more convenient.

Various material unwinding devices

Choose the correct unwinding device based on the characteristics of the material.

Intelligent conveyor system

Intelligent control of material transmission enables collaborative work of cutting and collection, enabling continuous cutting of ultra-long marks, saving labor and improving production efficiency.

The appeal of composite materials lies in their exceptional properties, but realizing their full potential requires a detailed understanding of the challenges posed by processing, especially in cutting applications. Complex fiber orientations, wear properties and different material properties require advanced techniques and tools to ensure perfect results. As technology advances, the field of cutting composites continues to evolve, with researchers and engineers constantly exploring innovative solutions to overcome these challenges and pave the way for widespread adoption of composites across industries.

For more information, please consult:

Email: aolcnc@aolcnc.com

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://aollaser.net/