Corrugated cardboard CNC knife cutting machine, also known as carton proofing machine and box making machine, is a special cutting machine that does not require die cutting for carton proofing, order exchange, and small batch packaging orders. The machine's workflow is automatic, including cutting, creasing, grooving, folding, etc. Instead of workers making cartons, it saves the time and cost of making cartons. In addition to cutting cardboard materials, it can also cut leather, polyester fiber boards, PP plastic hollow boards, rubber, asbestos gaskets and other materials.

Corrugated board CNC knife cutting machine technology is constantly updated and developed to meet the various needs of printing and packaging plants. It has the characteristics of fast speed, high precision and strong machine stability. It is suitable for the printing and packaging industry, digital graphics and text stores, electronics factories, mold factories, corrugated box factories, etc. It can cut various flexible materials, such as EPE foam, EVA foam, honeycomb panels, and cardboard, and is deeply loved by customers in various industries.

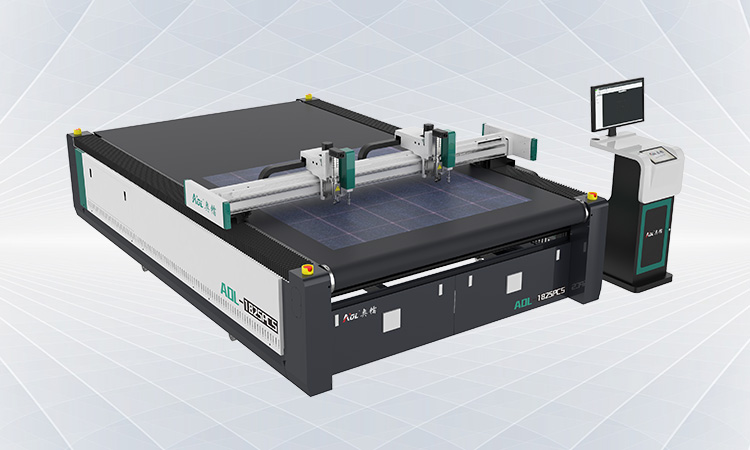

Features of corrugated board CNC knife cutting machine

1. AOL CNC knife cutting machine is used for corrugated cardboard cutting, equipped with oscillating knife and creasing wheel, grooving tools, etc. You can choose the appropriate knife according to the material thickness.

– Drag knife machine: It is specially designed for some thin materials within 5 mm. Compared with the vibrating knife, it is faster.

– Vibrating knife cutting machine: specially designed for thicker (more than 5mm) or harder materials, equipped with a special hardened tungsten steel blade, which is characterized by fast speed and smooth cutting edges.

2. Use the origami pressure wheel to fold the box easily. Therefore, we can choose the most suitable creasing wheel for folding production according to the thickness of your material. Our company can customize the creasing wheel for you.

3. Anti-collision and built-in automatic sensing device ensure worker safety.

4. Corrugated cardboard cutting CNC vibrating knife cutting machine is specially designed for mass production to maximize cost savings.

CNC knife cutting machines have wide and diverse applications in the packaging industry. They are widely used in the production of corrugated boxes, display racks, inserts and other packaging components. The ability to create complex shapes and designs makes these machines an integral part of packaging, not only protecting the contents but also serving as a marketing tool through visually appealing displays.

Integrating CNC knife cutting machines into corrugated board production has undoubtedly changed the packaging landscape. The combination of precision, versatility, speed and waste reduction has made these machines the cornerstone of modern manufacturing practices. As technology continues to advance, the packaging industry is likely to witness further innovations, with CNC knife cutting machines playing a key role in shaping the future of paperboard manufacturing.

For more information, please consult:

Email: info@aolcnc.com

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://www.aolcnc.com/