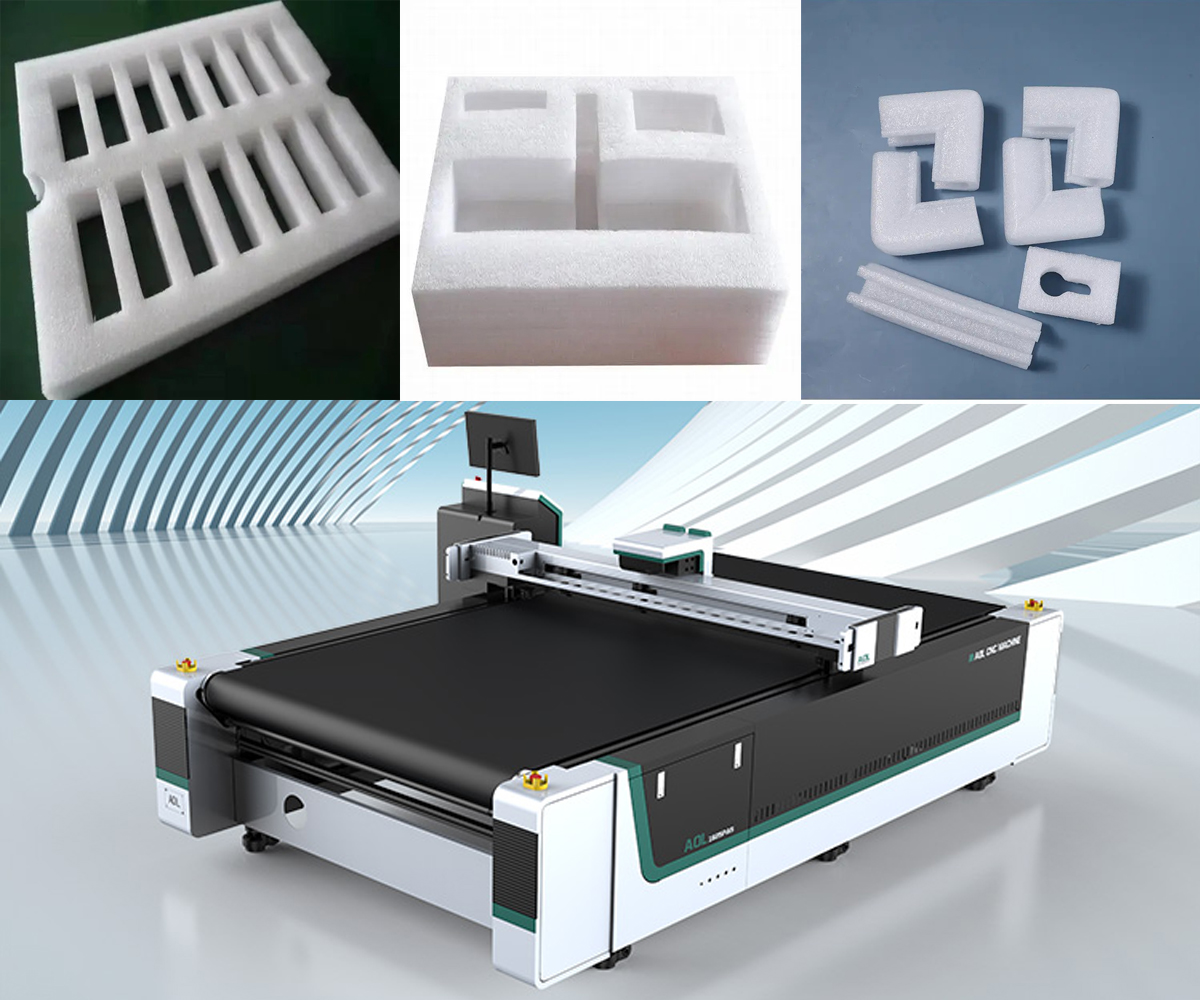

Digital cutting machines are computer-controlled machines that can cut a variety of materials accurately and quickly. They are used in a variety of industries, including arts and crafts, sign making, and clothing manufacturing. Digital cutting machines offer many advantages over traditional cutting methods such as hand cutting and die cutting.

What is Shadow Box Bubble?

Shadow Box Foam is a versatile and durable foam used to create custom inserts for shadow boxes. It's easy to use and can be cut into any shape or size, making it a popular choice among professional and amateur shadow box makers.

Benefits of using a digital cutting machine for shadow box foam cutting:

increase productivity

Speed: Digital cutting machines are much faster than traditional cutting methods. This can significantly reduce the time required to produce a foam shadow tool organizer.

Accuracy: Digital cutting machines are extremely precise, helping to reduce waste and improve the quality of the finished product.

Versatility: Digital cutting machines can be used to cut a variety of materials including foam, vinyl, fabric. This makes them a versatile tool that can be used for a variety of manufacturing tasks.

Reduce the need for manual labor: Digital cutting machines can automate the cutting process, allowing workers to focus on other tasks.

Improves the efficiency of the manufacturing process: Digital cutting machines help improve the flow of materials during the manufacturing process, thereby increasing productivity.

reduce waste

Reduces the need for manual intervention: Digital cutting machines can automate the cutting process, which helps reduce human errors and waste.

Improved material flow in the manufacturing process: Digital cutting machines help improve the material flow in the manufacturing process, thereby reducing waste and increasing efficiency.

Reduce downtime: Digital cutting machines are extremely reliable and require minimal maintenance, which helps reduce downtime and waste.

Digital cutting machines can reduce waste in the foam shading tool organizer manufacturing process by eliminating the need to purchase pre-made foam inserts, cut multiple layers of foam at once, and create complex shapes that would be difficult or impossible to cut by hand. This can help manufacturers save money and reduce their impact on the environment.

How to Cut Shadow Box Foam Using a Digital Cutting Machine

Step-by-step instructions for cutting shadow box foam using a digital cutting machine

1. Prepare the shadow box foam. Make sure the foam is clean and dry. If the foam is dirty, it will clog the cutting blade, making it difficult to cut the foam cleanly.

2. Place the shadow box foam in the digital cutting machine.

3. Set up the digital cutting machine. Choose the appropriate cutting blade based on the type of foam you want to cut. Set cutting speed and pressure according to manufacturer's instructions.

4. Design and tailoring. Use the digital cutting machine's software to design your cuts. You can import pre-made designs or create your own.

5. Cut the foam. After the design is complete, the cutting process begins. The digital cutting machine will cut the foam according to the design.

6. Remove the foam from the digital cutting machine.

7. Check for foam. Check the foam to make sure it cuts to your satisfaction.

A digital cutting machine is a valuable tool for businesses cutting shadow box foam. They offer many benefits, including increased productivity, improved quality, reduced waste and the ability to offer more customized products. If you are looking for ways to improve your shadow box foam cutting operation, I encourage you to consider purchasing a digital cutter.

FAQ:

What is the best type of digital cutting machine for cutting shadow box foam?

Considering the tool size, we recommend you 1600*2500mm. If your foam board size is larger, please consider 1600*3000mm.

If your foam is roller type, choose a conveyor table as your work surface. This saves a lot of time and effort in putting the foam on the table.

How to solve digital cutting machine problems?

Here are some tips on how to troubleshoot digital cutting machine problems:

Check the blade. Make sure the blade is sharp and clean. A dull or dirty blade can cause problems with cutting.

Check cutting speed and pressure. Make sure the cutting speed and pressure are set correctly for the type of foam you want to cut.

Check the cutting table. Make sure the cutting bed is clean and free of debris. Any debris on the cutting bed will interfere with the cutting process.

Check the foam. Make sure the foam is clean and dry. Wet foam is difficult to cut and can damage the machine.

Check the machine for any errors. If an error message appears on the machine display, consult the machine manual for troubleshooting instructions.

AOL intelligent blade cutting machine has high precision and high efficiency. Our professional after-sales service can provide automatic cutting solutions for various industries.

For more information, please consult:

Email: info@aolcnc.com

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://www.aolcnc.com/