-

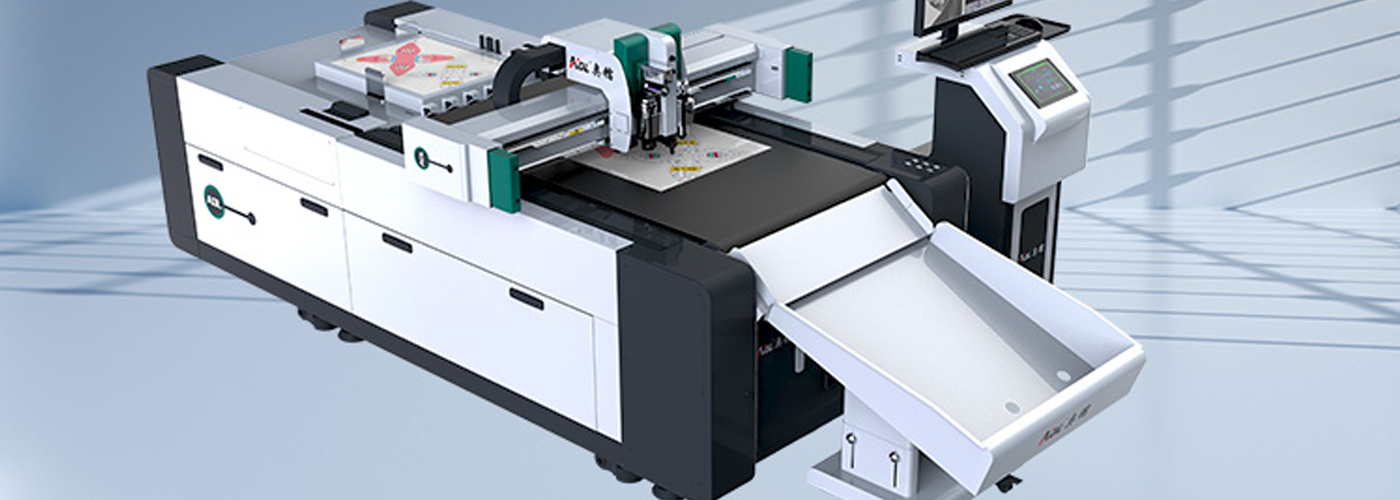

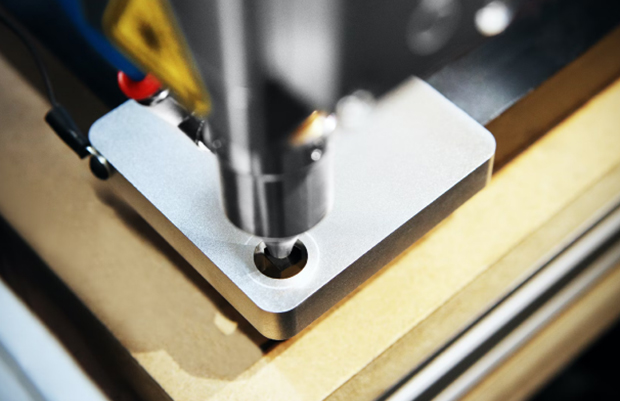

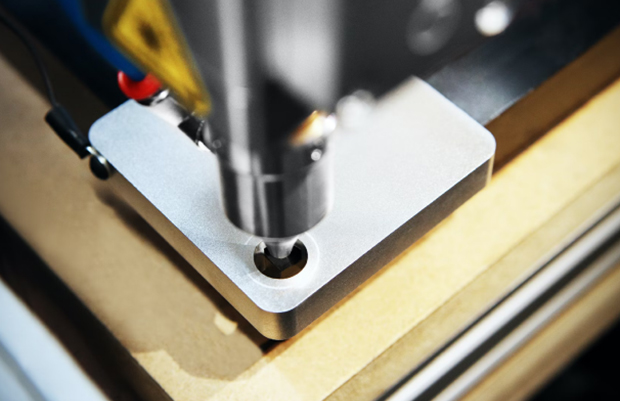

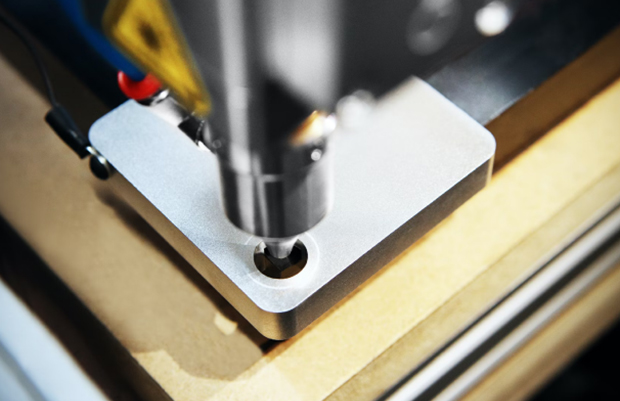

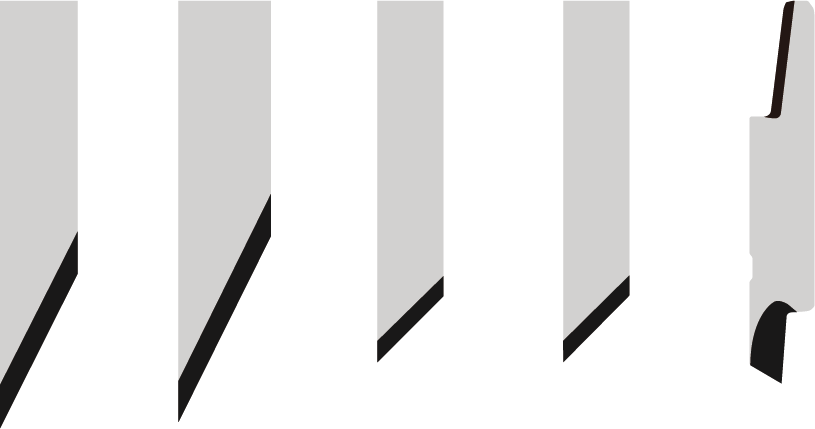

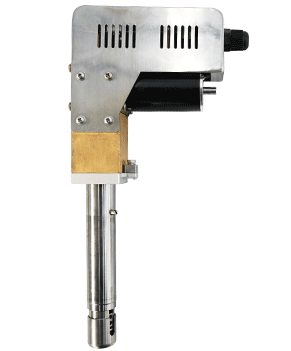

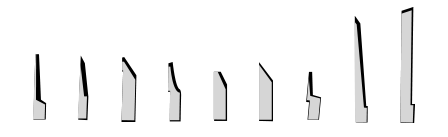

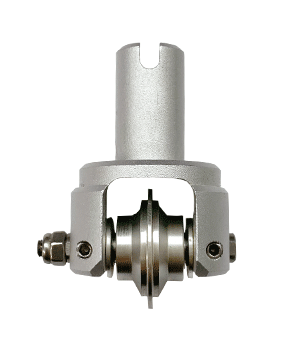

Circular knife puts the materials by the high-speed rotating blades driven by the servo motor.The tool can be installed with circular blades and decagonal blades .etc which are especially suitable for cutting woven materials

-

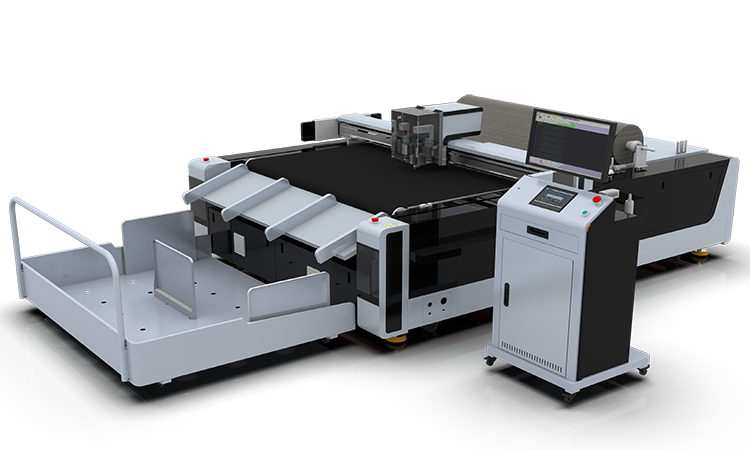

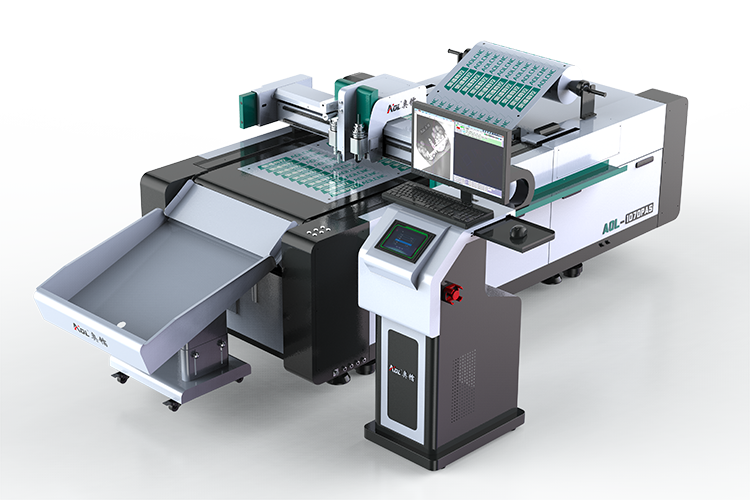

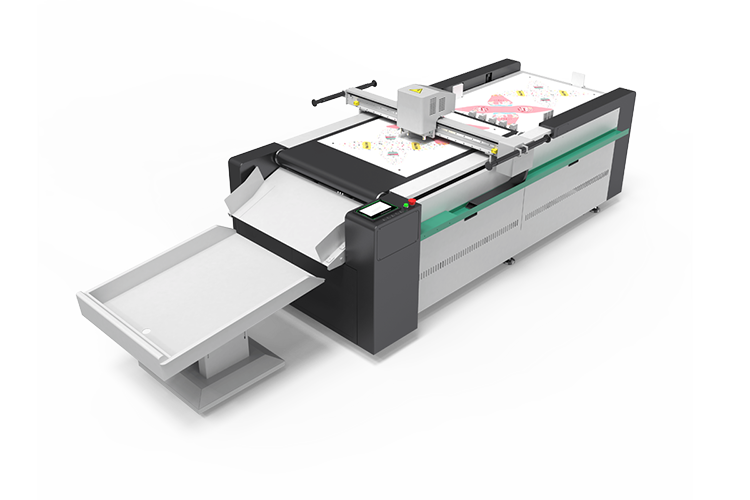

Applicable industries: Leather, Textiles, Fabric, No-woven Fabric, Fur, Multi-layer, Carpet, Sporting Goods and other industries