-

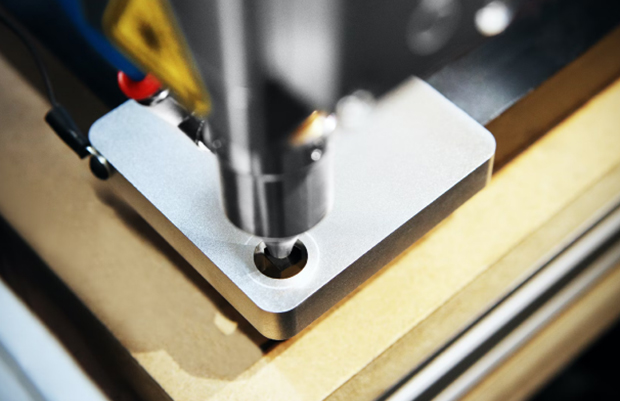

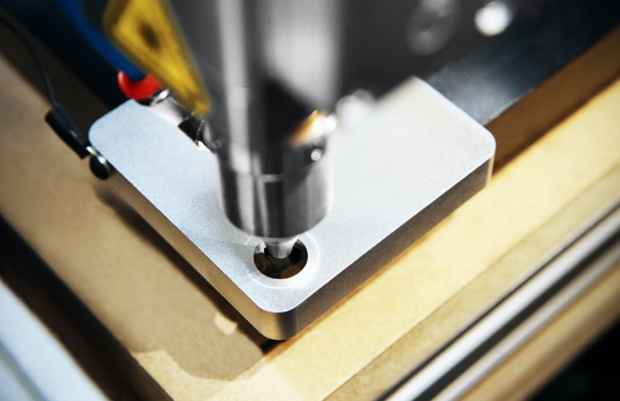

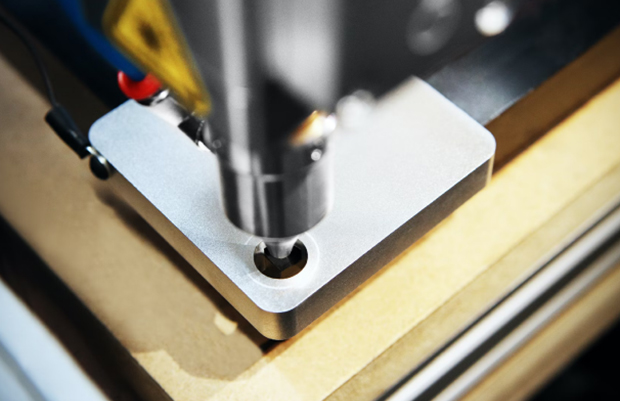

The Electrical Oscillating Tool is super suitable for cutting the material of medium density. Coordinated with various kinds of blades, applied for cutting different materials. It is very suitable for cutting medium density materials. With a wide variety of blades, it can be competent for cutting most flexible materials.

-

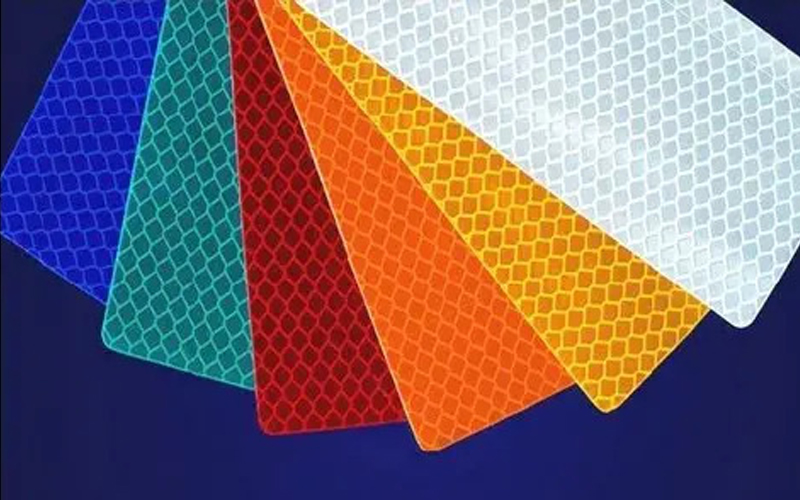

Applicable industries: Corrugated, Cardboard, Foam board, Honeycomb board, Car Mat, Seat Cover, KT board, Gray board, Leather, Fabric, Carpet, Composite Materials, etc