-

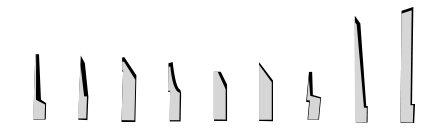

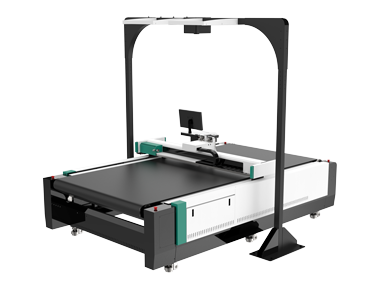

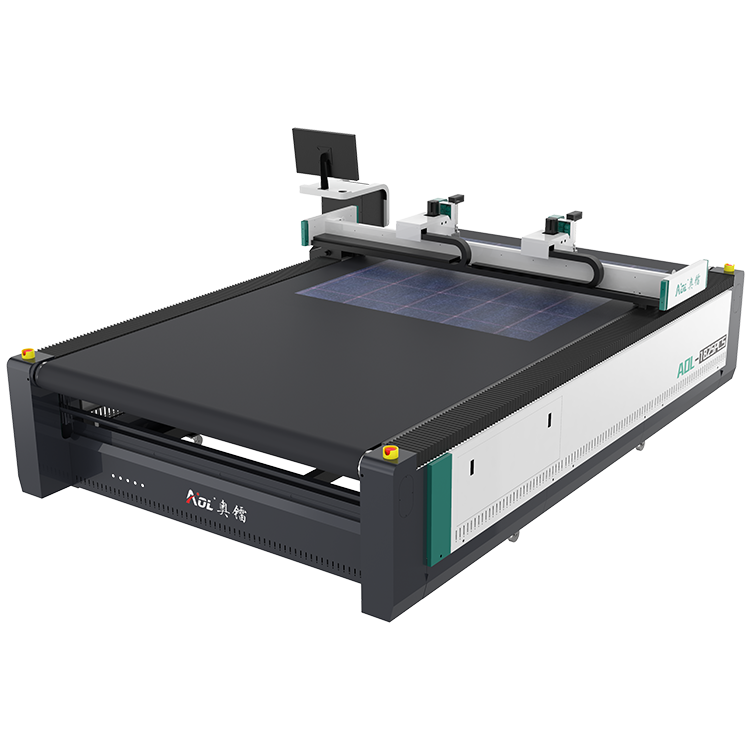

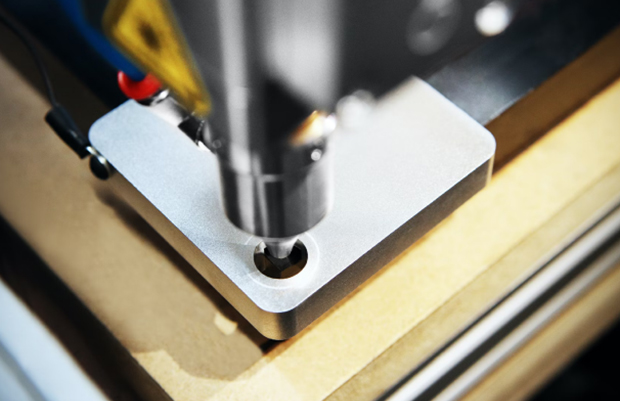

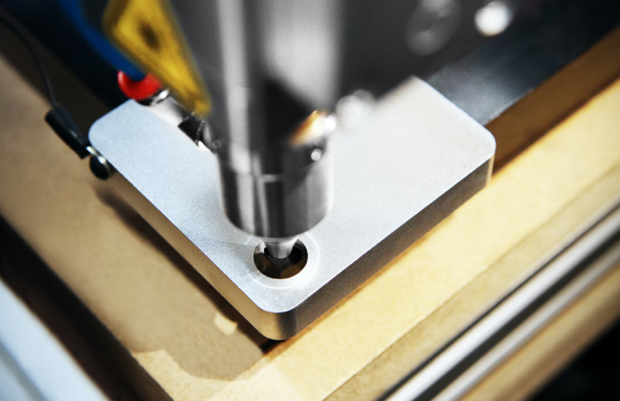

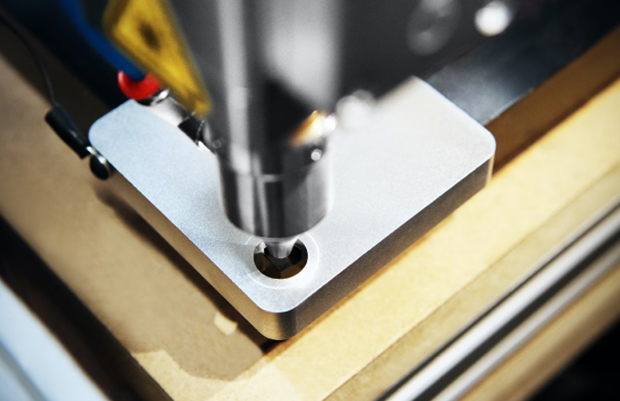

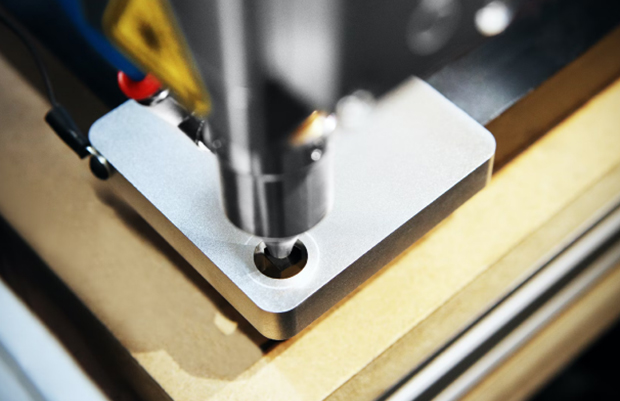

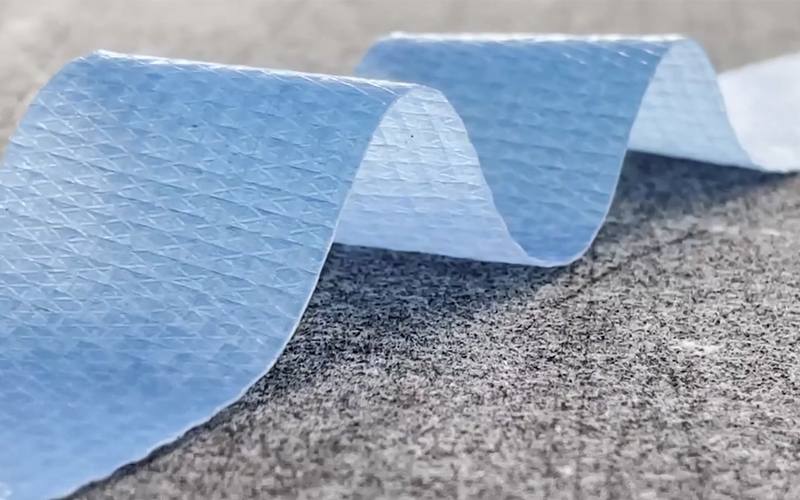

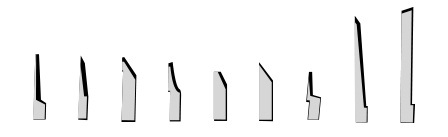

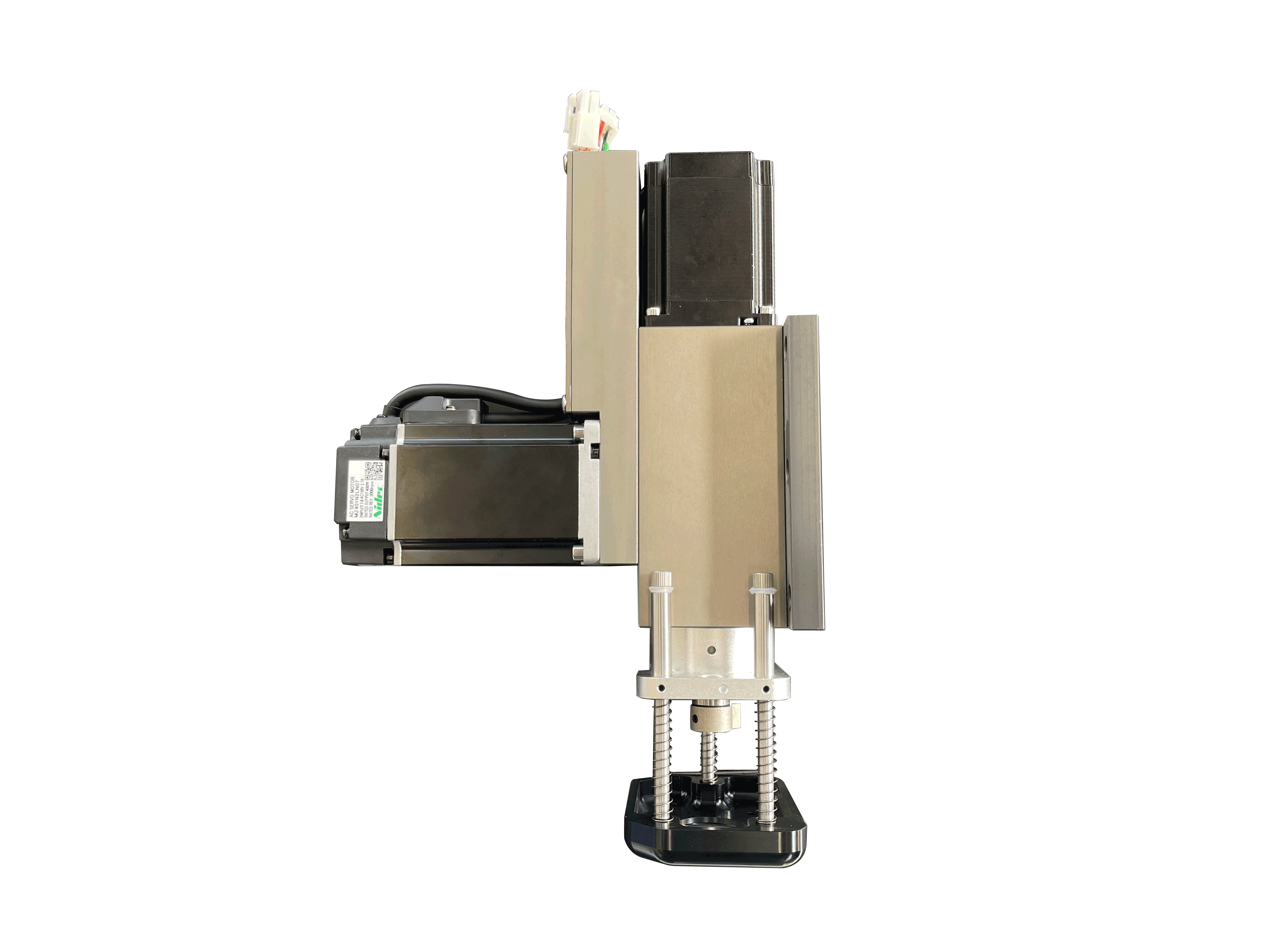

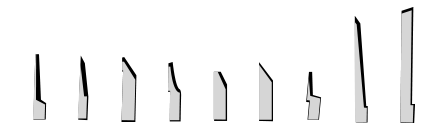

The Electrical Oscillating Tool is super suitable for cutting the material of medium density.Coordinated with various kinds of blades, applied for cutting different materials. The high-frequency vibration cutting of the blade up and down is controlled by the servo motor. The cutting effect is excellent. It is suitable for airtight cloth and plates below 2mm.

-

Applicable industries: Composite Materials, Corrugated, Cardboard, Carpet, Foam board, Honeycomb board, Car Mat, Seat Cover, KT board, Gray board, Leather, Fabric, etc