Cutting is an important processing means of industrialization, and its development affects the manufacturing and processing level of the whole country. With the refinement of processed products and the improvement of quality in social production, in addition to traditional mechanical cutting, new processing technologies such as oxygen cutting, plasma arc cutting, laser cutting, water jet cutting, and vibrating knife cutting have emerged. The development of technology has intensified the competition in the industry. As a new cutting method in the processing of flexible materials, vibrating knife cutting has become an , furniture industry and other necessary tools.

The processing technology level of the manufacturing industry is greatly affected by the overall level of the cutting tool industry. The vibrating knife cutting machine routinely increases high-frequency vibration on the cutting tool, which indirectly makes the tool body and parts contact, so that the old-fashioned cutting mode fundamentally occurs. changed. It is this change that solves the inherent problems in traditional cutting, such as vibration and thermal deformation in cutting, etc., and obtains excellent cutting effects. Compared with common cutting, vibrating knife cutting machine has the advantages of small cutting force, reduced cutting heat, improved surface quality of workpiece, convenient cutting, high tool durability, enhanced processing stability, and high production efficiency.

AOL CNC cutting equipment believes that the development of technology has intensified the competition among enterprises. As a new technology in precision machining and difficult-to-machine materials processing, the cutting process effect of vibrating knife has been unanimously recognized by the public. Within a certain range, it can effectively solve the problems of all difficult-to-cut processing materials and precision cutting processing, and has a series of characteristics in processing, which will surely usher in greater development opportunities in the future.

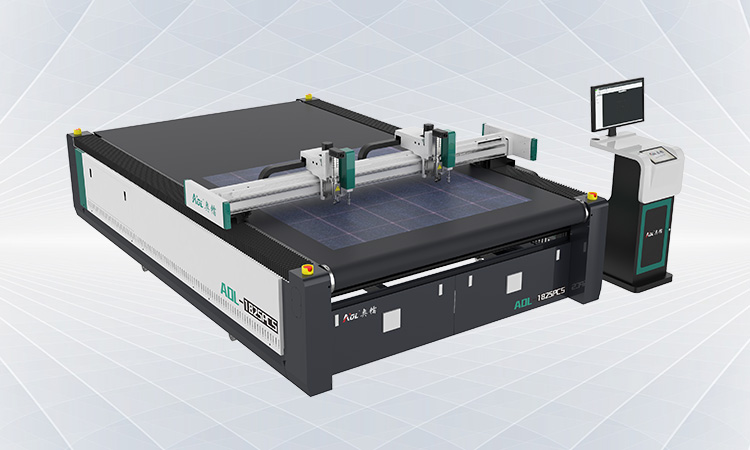

AOL CNC Cutting Equipment Co., Ltd. has been focusing on the technical research and development of intelligent cutting equipment for many years. Combined with the research and demonstration of a large amount of market data, it can provide mature integrated intelligent cutting solutions for major manufacturers. The vibrating knife cutting equipment produced is widely used in many industries such as leather, handbags, footwear, bags, clothing, car seats and interior decoration, sporting goods, stationery, household goods, etc. with the intelligent automatic cutting mode, and is recognized by the majority of merchants .

[High speed]: Unique intelligent prediction algorithm and improved control algorithm realize high-speed processing, smooth incision without flash, automatic closing, and no deformation.

[High Efficiency]: There is no need for die cutters and die-cutting machines, which can save a lot of manpower, die cutters and die-cutting machine costs.

[Cost Saving]: Completely replace manual design, proofing and cutting processes, helping you save a lot of manpower, tooling and material loss costs.

For more information, please consult:

Email: info@aolcnc.com

Phone: +86-0531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://www.aolcnc.com/