If you are a user who is using an oscillating knife cutting machine, you may encounter this situation-why is it equipped with a vacuum suction system, but there is still a problem of material movement during the cutting process?

why is it like this? Is your vacuum system not powerful enough? So how to solve this problem? This article will tell you the answer.

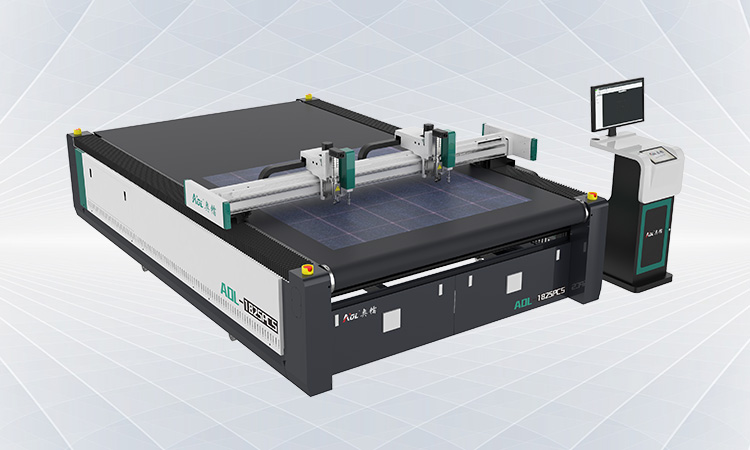

In order to ensure that the material is firmly fixed on the surface of the working platform and avoid displacement during cutting, we have equipped each vibrating knife cutting machine with a vacuum adsorption system, but there are still customers telling us that the material cannot be adsorbed. Perfect adsorption, they will wonder if the power of the vacuum adsorption system is too low?

It was even concluded that good material immobilization could not be achieved with a vacuum suction system.

According to the customer's feedback, we divided it into three situations, and made a detailed description of each situation and how to improve vacuum adsorption.

The first situation: the customer's understanding of the vacuum adsorption system is incorrect.

For example, one of our customers put a piece of A4 paper on the surface of the working platform after receiving the machine, and found that the material could not be fixed at all, so he concluded that the vacuum adsorption system could not work perfectly.

Is this really true? To understand this problem, we must first understand what the working principle of the vacuum adsorption system is.

The vacuum adsorption system uses atmospheric pressure as the force to form a closed space between the platform and the material. The vacuum pump pumps out a certain amount of gas molecules to reduce the pressure and form a pressure difference inside and outside the platform. Under this pressure, the material is absorbed and held firmly.

Through the above paragraphs, we found that in order to firmly adsorb the material on the workbench, a vacuum area must be formed between the material and the platform, so how to form a good vacuum area?

First, the entire surface of the working platform must be covered with material during machining.

We try to cover the entire surface of the working platform with material. The working platform can only be isolated from the outside space if it is completely covered. At this time, use vacuum adsorption to discharge all the air inside to form a good vacuum. In this area, the material is firmly adsorbed by the difference in air pressure. Instead of the customer I mentioned earlier, as long as a piece of A4 paper is placed on the working platform, its adsorption area is 1600mmX2500mm. At this time, 90% of the working platform is exposed and not isolated from the outside world. Therefore, even if the vacuum pump is working, a vacuum area cannot be formed on the surface of the material and the working platform, so that the effect of fixing the material cannot be realized.

Second, choose the appropriate vacuum adsorption system.

When the customer finds that the material is not adsorbed firmly, the first reaction is to increase the power of the vacuum adsorption system. Is it really?

We will configure a suitable vacuum adsorption system according to the size of the processing area selected by the customer. The basic principle is that the larger the worktable, the greater the power of the equipped vacuum adsorption, so as to quickly remove the gas inside the platform and form a vacuum state.

If the customer's effective processing area is less than 1600X2500mm, according to our experience, we will configure a 380V, 7.5KW vacuum adsorption system for the customer, which can perfectly realize the adsorption and fixation of the material; if the working area is 1600X3000mm or larger, we will configure it for the customer 9kw or 5.5KW X2 vacuum adsorption system.

If there is no special processing requirement (such as multi-layer cutting), we do not recommend configuring a super powerful vacuum system for a small working area, because it will increase the cost of purchasing and using the machine for customers, and the effect is not much different.

The greater the power of the vacuum adsorption system, the stronger the ability to generate negative pressure instantly, which is very necessary for large-format cutting machines. But we cannot simply think that the displacement of the material during processing is caused by the power of the vacuum adsorption system being too small, because as long as a vacuum area is generated between the material and the working platform, the material can be firmly fixed.

Some customers will ask: How can we know whether the adsorption effect is good? In fact, we equip each vacuum pump with a negative pressure gauge. When a vacuum area is formed between the working platform and the material, the negative pressure gauge will display pressure data, which means that a vacuum has been formed between the material and the platform. With a good vacuum area, the material can be firmly adsorbed on the working surface.

Through the above two points, we can understand:

As long as the entire working platform is covered and a suitable dynamic vacuum adsorption system is selected, a good adsorption effect can be guaranteed. On the contrary, if the working platform is not completely covered when you are working, even if you choose a high-power vacuum adsorption system, you cannot achieve perfect adsorption.

In the second case, the size of the processing material and the workpiece are different

In order to meet the processing of materials and workpieces of different sizes, the customer chose a super large format vibrating knife cutting machine. In actual use, when customers process large-sized materials, they can completely cover the working surface, thus playing a good adsorption effect, but when customers process small-sized materials, they cannot absorb well.

How to solve this situation?

We ask customers to cover the exposed working area with an airtight film to achieve a good adsorption effect. Using this method can solve this problem very well, but customers will find it too troublesome and want a smarter solution.

This is also possible, that is the "partitioned adsorption method", that is, the working platform is divided into several independent units, which can be closed and opened by the control system to process materials of different sizes and achieve the best adsorption effect. There are four modes of partition adsorption: manual partition, map partition, follow partition, and one-zone follow mode.

So how does each mode work? How should customers use it? Let me answer it for you.

Manual zoning: Before starting cutting, customers can manually select which areas to turn on the adsorption, which areas to turn off the adsorption, or all areas are in the open adsorption state according to the size of the processed material. This mode is mostly used for materials that cannot cover the entire processing area, and the size of a single cutting pattern is larger than the size of a single suction area.

Partition by image: The machine automatically opens the required adsorption area according to the size of the processed image to achieve the best adsorption effect. This mode is suitable for cutting very large graphics.

Follow the partition: The machine will automatically open the adsorption of this area and the nearby area according to the change of the tool position to ensure smooth cutting. This method is suitable for situations where the size of the material is large but the size of the workpiece to be cut is small.

One area follows one area: It means that the machine automatically turns on the adsorption function of the area according to the area where the tool is located, so as to ensure that the material in this area is cut. This mode is suitable for cutting small-sized, densely nested graphics.

Through the above introduction, you will know how to solve the problem of poor adsorption when large machines cut small materials. We use the working area to divide the adsorption area, and set which positions to turn on the adsorption and which positions to turn off the adsorption according to the size of the material, so as to ensure the formation of a vacuum area between the material and the adsorbate. Working platform to secure the material on the working surface.

Can the method of partition adsorption solve all the problems of poor adsorption? The answer is no, when we cut airtight materials, we can use the partition adsorption method to enhance the vacuum adsorption capacity. But when the material itself has air permeability, this method cannot achieve a good fixing effect. This is also a misunderstanding of many customers. Therefore, even if the partition adsorption system is installed, the adsorption capacity of the machine cannot be improved at all.

The reason for this phenomenon is that the customer does not really understand the principle of vacuum adsorption, and there is another very important reason, that is, the factory that produces the machine does not know the material characteristics of the customer, so it cannot provide the customer with the correct solution.

So, is there a solution for breathable materials?

The answer is: yes.

The third case: how to improve the adsorption effect of breathable materials

When we use a vibrating knife cutting machine to cut breathable materials, due to the breathable characteristics of the material, it is difficult to form a vacuum area between the material and the working platform, so the material is easy to move during the cutting process. Processing, resulting in cutting can not be carried out smoothly.

We can classify this situation according to the material as follows:

Textile and fabric materials. For this material, we can use a special custom-made knife - a round ten-point blade, which can effectively reduce the stretching of the material by the knife during the cutting process and ensure smooth cutting;

Sheet material. For example, polyester sound-absorbing panels, which have the characteristics of good air permeability, cannot be processed with special tools, which is easy to cause displacement during processing.

The initial solution is to use the hard object blocking method to use the high hardness of the material itself to block the surrounding of the material, so as to avoid the displacement of the material. Although this method can solve the displacement problem of standard size materials, it is not suitable for non-standard size materials. Standard size material doesn't hold well and won't accommodate uneven boards. So not a perfect solution.

In order to better solve this problem, the R&D engineers of AOL CNC have developed a followable covering system after many simulation experiments. A set of covering systems are installed at the front and back of the machine beam (Y axis), and there are running tracks that can move forward and backward with the beam and shrink freely. When the front material is cut, the back cover system opens. When the rear material is cut, the front cover system opens to enhance suction.

The above are the three situations and solutions that we have summarized that the vacuum adsorption system cannot perfectly fix the material. Hope it helps you. Which vacuum adsorption method is more suitable for you? I believe you already have the answer. Or you can also contact us to provide you with professional guidance.