One of the most common questions in our lives at this time is whether it is more convenient to use a die-cutting machine or a digital cutting machine. Big companies offer die cutting and digital cutting to help customers create unique shapes, but everyone doesn't know the difference between them.

In the world of crafting, scrapbooking, and DIY projects, the right cutting machine can make all the difference. Two popular options among hobbyists are die cutting machines and digital cutting machines. Each method has its own advantages and limitations, and choosing between the two depends on your specific needs and preferences. We’ll explore the key features, benefits, and considerations related to die cutting machines and digital cutting machines to help you make an informed decision.

For most small companies that don't have such solutions, it's not even clear whether they should buy them in the first place. Many times, as experts, we find ourselves in the awkward position of having to answer this question and provide advice. We first try to clarify what is meant by the terms "die cutting" and "digital cutting".

Die cutting machine:

In the printing world, die cutting provides a quick and inexpensive way to cut large quantities of print into the same shape. The artwork is printed on a square or rectangular piece of material (usually paper or cardboard), which is then placed into a machine with a custom "die" or "punch block" (a wooden block with a metal blade) that is bent and fold into desired shape). As the machine presses the sheet and mold together, it cuts the shape of the blade into the material.

Digital cutting

Unlike die cutting, which uses a physical mold to create a shape, digital cutting uses a blade that follows a computer-programmed path to create the shape. Digital cutting machines consist of a flat workbench area and a set of arm-mounted cutting, milling and scoring attachments. The arms allow the tool to move left, right, forward and backward. The printed paper is placed on the workbench and the cutting machine follows a programmed path through the paper to cut out the shape.

Die cutting machine:

Mechanical accuracy:

Die-cutting machines operate on mechanical systems where metal dies are used to cut specific shapes and patterns. These dies come in a variety of designs and are placed on a cutting mat with the material you want to cut.

Versatility:

Die-cutting machines are versatile and can cut a variety of materials, including paper, card stock, fabric, and even thin metal. They are especially popular in the world of scrapbooking and card making.

High cost performance:

Traditional die-cutting machines are generally more affordable than digital die-cutting machines, making them an attractive option for hobbyists or those on a tight budget.

Manual operation:

One of the disadvantages of die-cutting machines is that they usually require manual operation. This means you have to turn the crank or press a lever to engage the cutting mechanism.

Digital cutting machine:

Precision and complexity:

Cut intricate designs with high precision using computer-controlled blades. This allows for more complex and detailed projects.

Customization and creativity:

Digital cutting machines excel at customization. Many mockups come with software that allows you to create your own design or download pre-made templates, offering a wide range of creative possibilities.

Easy to use:

Unlike manual die-cutting machines, digital die-cutting machines are generally easier to use. They require minimal physical labor, and the cutting process can be controlled from a computer or even a mobile app.

Material Compatibility:

While digital cutters are great for cutting paper and vinyl, they can have difficulty cutting thicker materials like particleboard or leather. It is important to check the machine's specifications to ensure it meets your material requirements.

Which is the better choice?

How do you choose between two cutting solutions? The simplest answer is: "It all depends on the type of job. If you want to trim a lot of smaller items printed on paper or card stock, die cutting is a more cost-effective and time-efficient option. Once the die is assembled, It can be used over and over again to create large numbers of the same shapes - all in a fraction of the time of a digital cutting machine. This means that by using a custom mold for a large number of projects (and/or repurposing it for future additional printing), can offset to some extent the cost of assembling custom molds.

However, if you want to trim a small number of large-format items (especially those printed on thicker, tougher materials like foam board or R-board), digital cutting is a better option. There's no need to pay for custom molds; plus, you can create more complex shapes with digital cutting.

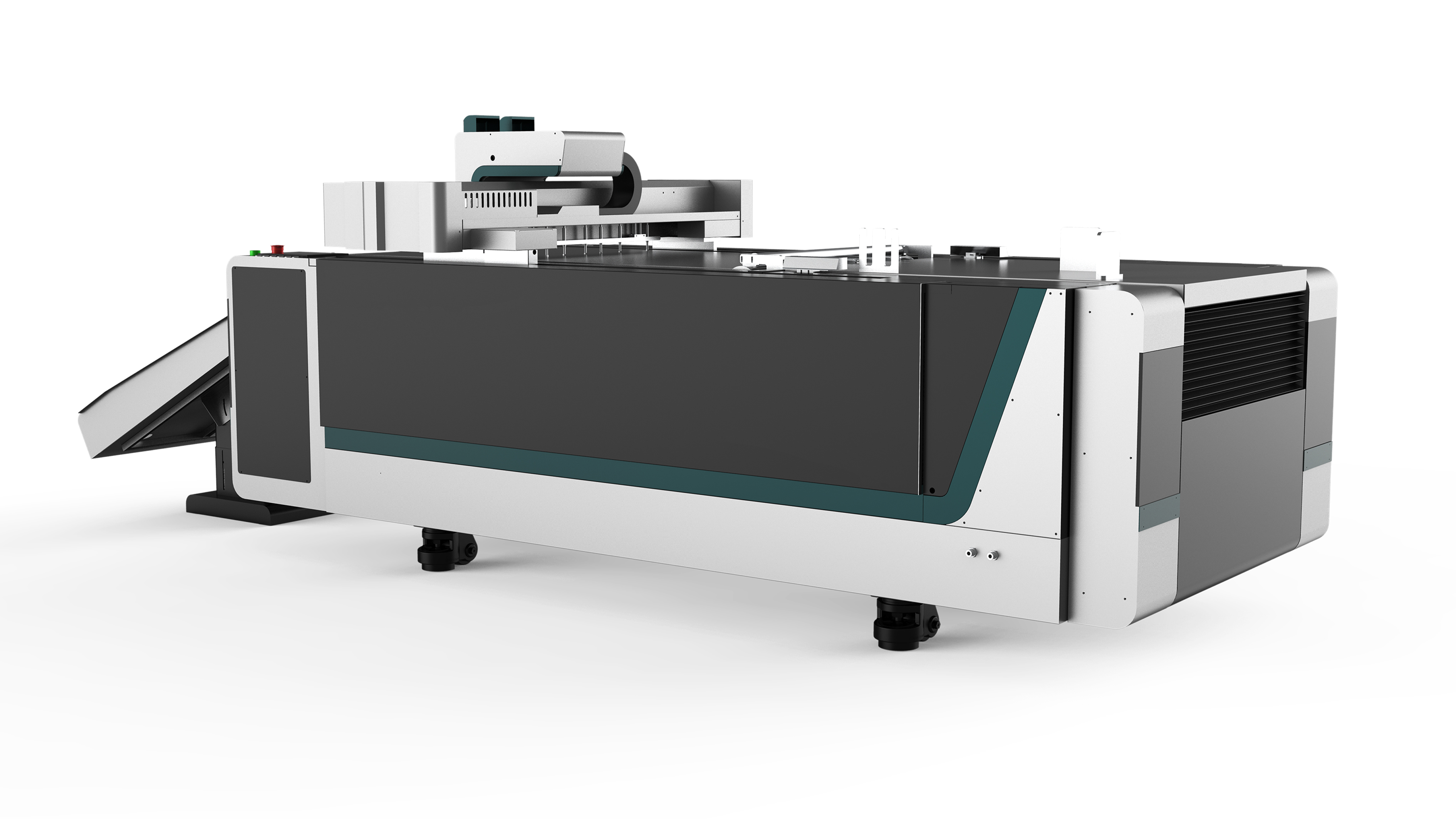

The AOL high-speed digital cutting system can automatically and accurately perform through-cutting, kiss-cutting, milling, V-groove, indentation, marking and other processing for single-layer (several-layer) cutting. Widely used in automotive interiors, advertising, clothing, furniture, composite materials and other industries. The 1070 cutting system provides automated cutting solutions for various industries with its high precision, flexibility and efficiency.

If you still want to know more about us, please click here to leave a message to contact us!