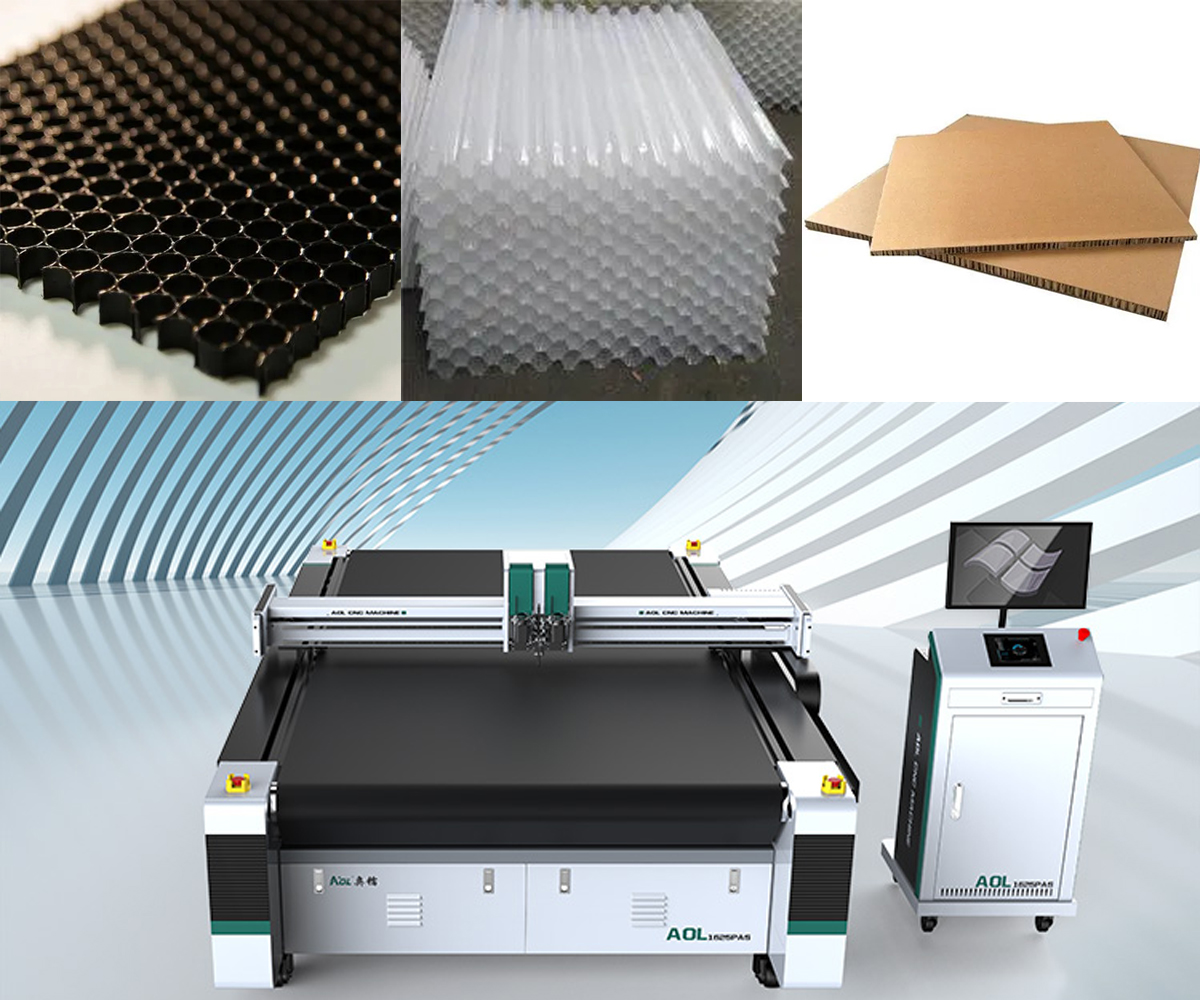

Activated carbon honeycomb panels are uncommon materials in life. Mainly used for filtration, some also have decolorization effect. The material of activated carbon honeycomb panels is brittle and hard. Due to its characteristics, laser cutting cannot be used, nor can some blade cutters.

Against the brittleness of the material, the vibrating knife cutting machine can solve this problem very well.

The vibrating knife cutting machine adopts computer-controlled blade cutting, which is in line with the concept of environmental protection and green activated carbon honeycomb panel material.

Activated carbon honeycomb panel cutting machine cutting principle:

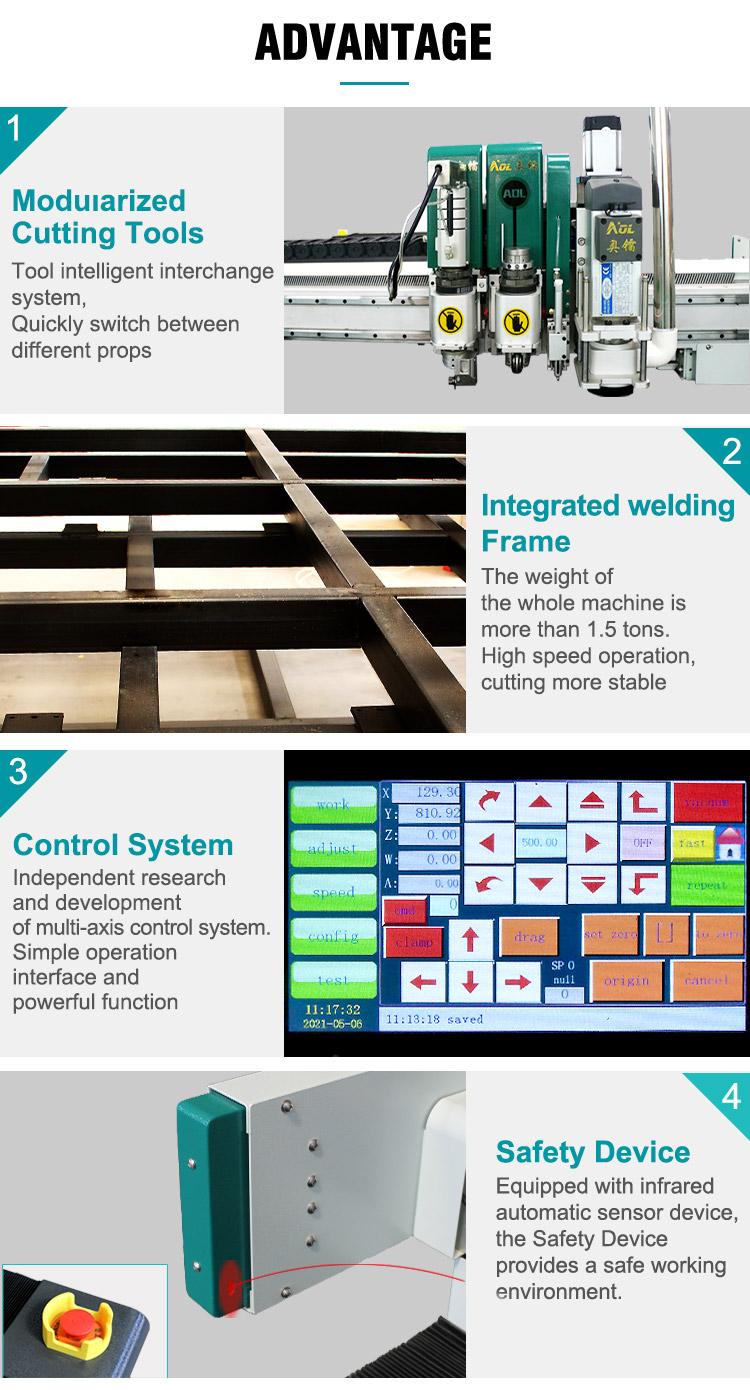

The activated carbon honeycomb panel pneumatic knife cutting machine uses the pressure of the air source to push the knife to reciprocate, thereby generating cutting force, similar to the saw blade in life, the reciprocating speed of the activated carbon honeycomb panel cutting machine is extremely fast, and its cutting effect and cutting thickness are uniform to the best standard.

Activated carbon honeycomb panel cutting machine configuration:

The activated carbon honeycomb panel cutting machine adopts a welding machine integrated frame, and has undergone a high-temperature heat treatment process to ensure that the equipment does not deform or shake during high-speed and long-term operation. The working surface adopts aviation alloy technology, which is wear-resistant and corrosion-resistant. The electrical equipment of the whole machine adopts imported configuration, which guarantees the service life and failure rate. Since the material of activated carbon honeycomb panels is relatively brittle, some debris will be generated during the cutting process, and activated carbon has partial conductivity. Insulation treatment will also be used to ensure the normal use of the equipment.

Advantages of activated carbon honeycomb panel cutting machine:

1. Infrared sensor system, 360° surrounding safety, to ensure the safety of the operator.

2. Perfect camera positioning system, support ● or ten marks, etc., to improve work efficiency.

3. The solid aluminum honeycomb platform has good suction effect, ensures the platform is flat, and does not deform after long-term use.

4. Flexible tool system, compatible with all series of tools.

5. Efficient anti-dry roll feeding system, complete feeding and cutting within 5 seconds; enable the machine to realize automatic continuous cutting.

6. Powerful CAD editing and design software, perfectly matched with multiple software; and supports barcode reading, avoiding the operator from sending wrong cutting files and improving work efficiency.

7. The parameter setting system can adjust the best cutting parameters according to different materials to ensure the accuracy of each cutting.

8. The overall frame structure is designed by senior engineers in the industry, which is simple, stable, and easy to install and carry.

9. Precise knife setting system, easy to operate, can accurately control the depth of the knife and prolong the use time of the mat.

10. Scientific and concise wiring system and chassis circuit design, stable and safe; equipped with all tool interfaces to support subsequent upgrades; easy to install and maintain.

That’s all for the introduction of the activated carbon honeycomb panel cutting machine. If you still want to know more, you can contact us through the following ways, or explain what you want to know through the contact page on the website, and we will have a professional The staff will answer for you in the first time!

Email: info@aolcnc.com

Phone: +86-0531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://www.aolcnc.com/