The sound insulation cotton cutting machine is a special equipment specially designed for the precise cutting of sound insulation cotton materials in various industries. It plays a vital role in the production and installation of sound and sound insulation products.

The main function of the sound insulation wool cutting machine is to efficiently and accurately cut sound insulation materials such as fiberglass, mineral wool, foam or other synthetic fibers into the desired shape and size. This allows customization to specific project requirements, ensuring optimum performance in noise reduction and acoustic control applications.

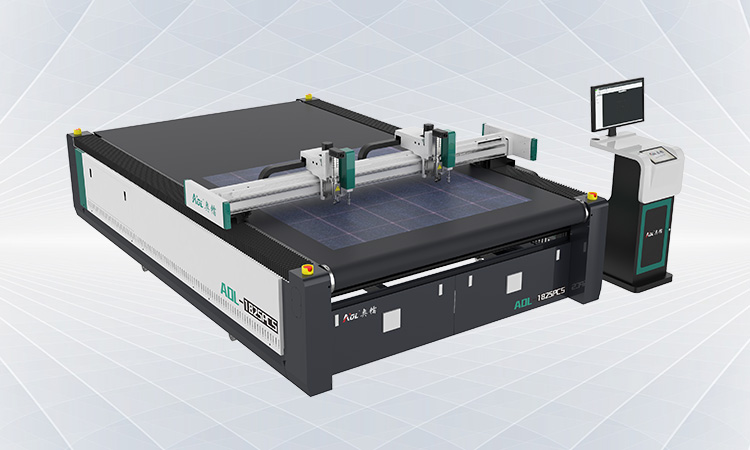

The machine uses advanced cutting technology, usually with high-speed rotating blades for cutting, and the specific model and specification depend on the material to be cut. The precise and controlled cutting process results in a clean and even cut without damaging or deforming the sound insulation material.

The main advantage of using an acoustic wool cutting machine is its ability to increase productivity and efficiency. Manual cutting methods can be time-consuming, laborious, and error-prone, resulting in inconsistent end products. Using cutting machines, manufacturers can achieve higher productivity, minimize waste, and ensure consistent quality in all sound insulation they produce.

In addition, the sound insulation cotton cutting machine offers flexibility and versatility in terms of cutting patterns and sizes. It can cut various shapes, such as coils or specific geometric designs, through uploaded file patterns, enabling manufacturers to meet different customer requirements. This adaptability is especially beneficial in industries such as construction, automotive, aerospace and HVAC (heating, ventilation and air conditioning), where sound insulation and noise control solutions need to be customized for different applications.

Cutters contribute to workplace safety by automating the cutting process and reducing the need to manually handle sharp tools. The operator can load the sound-deadening material onto the machine, set the desired cutting parameters, and monitor the process from a safe distance. This helps reduce the risk of accidents, increases operator efficiency and creates a safer work environment.

To sum up, the sound insulation cotton cutting machine is an essential tool for manufacturers in the sound insulation industry. It enables efficient, precise and customizable cutting of sound insulation materials, ensuring optimum performance and meeting the specific requirements of different applications. By streamlining production processes and improving product quality, this machine contributes to the overall effectiveness and success of sound insulation projects across industries.

If you want to know more about the sound insulation cotton cutting machine, please contact us, we will give you detailed answers in the first time!