By utilizing cutting-edge CNC and CAD technology, digital cutters can precisely create precise fabric patterns. This unique approach reduces production time, reduces waste caused by human error, and maximizes efficiency in the apparel industry.

Our cutting-edge equipment is capable of producing large quantities of garments quickly and cutting multiple layers at a time.

Complex shapes and patterns can be easily achieved using a CNC digital knife cutting machine. Intricate designs that would normally take hours to cut by hand can now be completed in record time, allowing you to create professional garments with one-of-a-kind details.

With the help of innovative cutting machines, apparel manufacturers can now introduce a variety of fabrics into their designs, from luxurious leather to soft cotton and everything in between! From classic denim to delicate silks – fashion designers around the world have all the materials they need to create stylish creations.

Garment manufacturers can benefit from the convenience of CNC digital knife cutting machines. This technology enables designers to quickly prototype their ideas and quickly execute production runs, helping them get products to market faster than ever before!

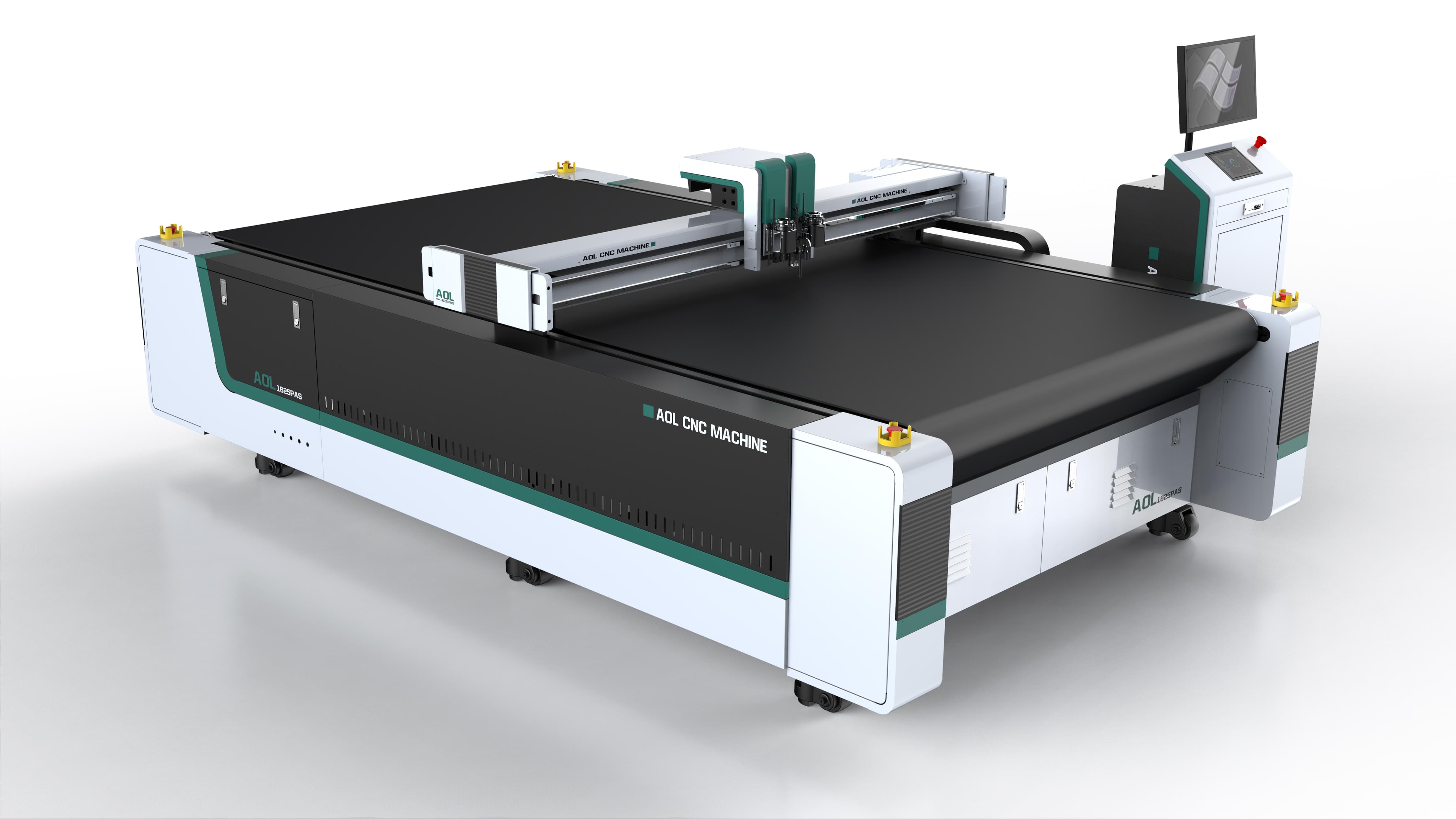

Equipment data of AOL clothing fabric cutting machine:

|

Technical parameters / model |

AOL-1625 |

AOL-1825 |

| Effective working area | 1600x2500mm | 1800x2500mm |

| Multi-function tool | Pneumatic knife, projector,vibrating knife,Round knife | |

| safety devices | Using infrared sensors, responsive, safe and reliable,Anti-collision system,Four corner emergency stop button | |

| Cutting speed | 300-2000mm/s | |

| Cutting thickness | ≤50mm Other thicknesses can be customized according to the material | |

| Applicable materials | Long-haired carpets, carpets, car floor mats, textile carpets, cotton and linen carpets, Particle fleece,Diatom mud carpet, fake wool carpet, printed carpet,etc. | |

| Material fixing method | Vacuum partition adsorption | |

| Transmission port | Network port | |

| Transmission system | The X\Y axis is divided into two kinds of rack or belt | |

| rated power | 11kw | |

| Rated voltage | 380V±10%/220V±10% Optional | |

| Control System | Chinese and English LCD touch screen | |

| Operating environment | Panasonic servo motor, high precision helical gear reducer, Taiwan Yintai rail, Germany Henryan rack, Omron sensor, Schneider low-voltage appliances, Taiwan Mingwei power supply, Germany cable, 42mm adsorption platform, automatic feeding, Taiwan rail, energy saving fan | |

| Support file format | AI、PLT、DXF、PDF、 PCE、XML | |

| Overall size | 3600*2400*1250 |

3600*2600*1250 |

What is a cutting machine for the garment industry?

Cutting machines are the lifeblood of any garment and garment production process. These devices provide a reliable, accurate method to quickly transform fabric into custom pieces for garment making. From small manual cutters to large industrial machines with different types of blades, these cutters allow companies to get results faster than ever before, improving efficiency while reducing costs associated with wasted material and manual labor time.

Manufacturers like AOL can choose from various types of cutting technologies based on their unique needs, all of which offer unique advantages that depend on project requirements. By harnessing the power of these modern tools, manufacturers across industries are unlocking new levels of productivity within their organizations and achieving incredible success!

Working video of AOL clothing fabric cutting machine:

Why use AOL clothing fabric cutting machine to cut materials?

If you've been working in the apparel industry for a while, you know that cutting fabric and other materials is a critical part of the process. It takes precision, accuracy and a lot of patience to get it right. However, with the introduction of digital knife CNC tools, the entire process has become more streamlined, efficient and accurate.

Digital Knife CNC cutting machines have changed the way the clothing and apparel industry operates. It's a way to cut fabric and other materials quickly, efficiently, and accurately, reducing the chance of waste and increasing productivity. From precision and accuracy to cost-effectiveness and versatility, the benefits of using CNC tooling are endless. So, if you are in the apparel industry, now is the perfect time to invest in a digital tool CNC cutting machine to speed up production, reduce lead times, and improve the quality of the final product.

Digital cutters are ideal for cutting multiple layers of fabric at the same time, especially when speed and accuracy are critical. This saves time and effort compared to traditional manual cutting methods. Digital knife cutting machines are particularly useful when cutting complex patterns and designs because they produce clean and precise cuts that are not possible using manual cutting methods.

- High precision and accuracy: One of the biggest advantages of using a digital knife CNC cutting machine is that it provides high precision and accuracy with every cut. With a digital knife CNC cutting machine, you can cut fabric with high precision, reducing the chance of errors and waste. Unlike traditional cutting tools, digital tooling CNC cutting tools can produce complex shapes and curves, ensuring the final product is of superior quality.

- Time-saving ability: Another important feature of CNC tools is the ability to save time during the production process. This is because it is a computerized process where the cutting machine is controlled by software to accurately cut the desired pattern. You can easily enter your design into your computer and your cutter will handle the rest. This not only saves time but also reduces workload, thereby increasing productivity.

- Cost-Effectiveness: A digital knife CNC cutting machine is a one-time investment that can bring many benefits in the long run. Although this may seem like a huge expense at first, you'll soon realize that it's more cost-effective than traditional cutting methods. You can save on material costs as it offers the opportunity to cut accurately and reduce waste. Additionally, it saves on labor costs because it only requires one operator to run, unlike traditional cutting methods that require multiple operators.

- Versatility and Flexibility: CNC tools offer incredible versatility and flexibility. It can cut various types of materials with ease, including fabric, leather, foam, rubber, and more. This means you can use one cutter for a variety of cutting needs, making it a valuable investment for your business. Additionally, it can cut complex shapes and designs that are nearly impossible with traditional cutting methods.

- Efficient production: Digital knife CNC tools are used to ensure efficient and high-quality production. It reduces lead times and allows for mass production, making it ideal for businesses of all sizes. Since it is computerized, the possibility of human error is reduced, ensuring the final product is of the highest quality.

AOL intelligent blade cutting machine has high precision and high efficiency. Our professional after-sales service can provide automatic cutting solutions for various industries.

For more information, please consult:

Email: info@aolcnc.com

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://www.aolcnc.com/