What is digital cutting?

With the advancement of the times, the advent of work 4.0, and the emergence of computer-aided manufacturing, a new type of digital cutting technology has been developed, which combines most of the advantages of die-cutting with the flexibility of computer-controlled precision cutting of highly customizable shapes. Unlike die-cutting, which uses a physical mold of a specific shape, digital cutting uses cutting tools to follow a computer-programmed path to cut out the desired shape. Commonly used cutting tools are vibrating knives, pneumatic knives, oblique cutting, half cutting, milling cutters, pressure rollers and other cutting tools.

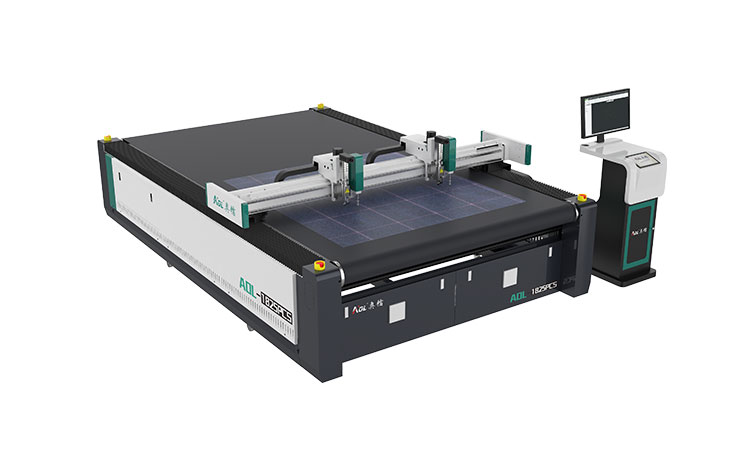

The digital cutting machine consists of a flat table area and a set of cutting, milling and scribing tools mounted on a positioning arm that moves the cutting tools in two dimensions. The sheet is placed on the table surface and the tool cuts the pre-programmed shape along a programmed path through the sheet.

Cutting is a versatile process used to shape materials such as rubber, textiles, foam, paper, plastics, composites and foils by trimming, forming and shearing. AOL CNC provides professional products and technical services for more than 10 industries such as composite materials, printing and packaging, textile and clothing, automotive interiors, advertising printing, office automation, and luggage.

Digital cutting enables large format custom cuts:

The biggest advantage of digital cutting is that no shape-specific dies are required, ensuring shorter turnaround times compared to die-cutters as there is no need to switch between die shapes, reducing overall production time. Additionally, there are no costs associated with the manufacture and use of molds, making the process more cost-effective. Digital cutting is especially suited for large format cutting jobs and rapid prototyping applications.

Computer-controlled digital flatbed or conveyor belt cutters can easily combine registration mark detection on the material with immediate control of cut shapes, making digital cutters very attractive for highly customizable automated manufacturing processes.

The growing popularity of digital cutting machines has led manufacturers to offer a wide range of digital cutting solutions in the market, from large industrial machines that can handle a few square meters of material to hobbyist-grade cutting machines for home use.

Digital cutting can also increase your productivity in several ways. Whether you're producing one-off jobs or high-volume production, you can reduce setup time, optimize repeatability and improve cut quality. Digital cutting allows you to expand and differentiate your product offering at any time. You become more flexible in order planning and processing and can make changes quickly, economically and on the fly.

AOL intelligent blade cutting machine has high precision and high efficiency. Our professional after-sales service can provide automatic cutting solutions for various industries.

For more information, please consult:

Email: info@aolcnc.com

Phone: +86-0531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://www.aolcnc.com/