Digital cutting enables manufacturers to incorporate delicate and odd-shaped parts made of a variety of materials into advanced product designs.

Cutting is a versatile process used to shape materials such as rubber, textiles, foam, paper, plastics, composites and foils by trimming, forming and shearing. For decades, digital cutting has been the standard manufacturing method, allowing manufacturers to achieve high-volume production of parts that previously took longer or cost more to manufacture using other techniques.

What is digital cutting?

With the advent of computer-aided manufacturing, a new type of digital cutting technology was developed that combines most of the advantages of die-cutting with the flexibility of computer-controlled precision cutting of highly customizable shapes. Unlike die-cutting, which uses a physical mold for a specific shape, digital cutting uses a cutting tool (which can be a static or vibrating blade or milling cutter) to follow a computer-programmed path to cut out the desired shape.

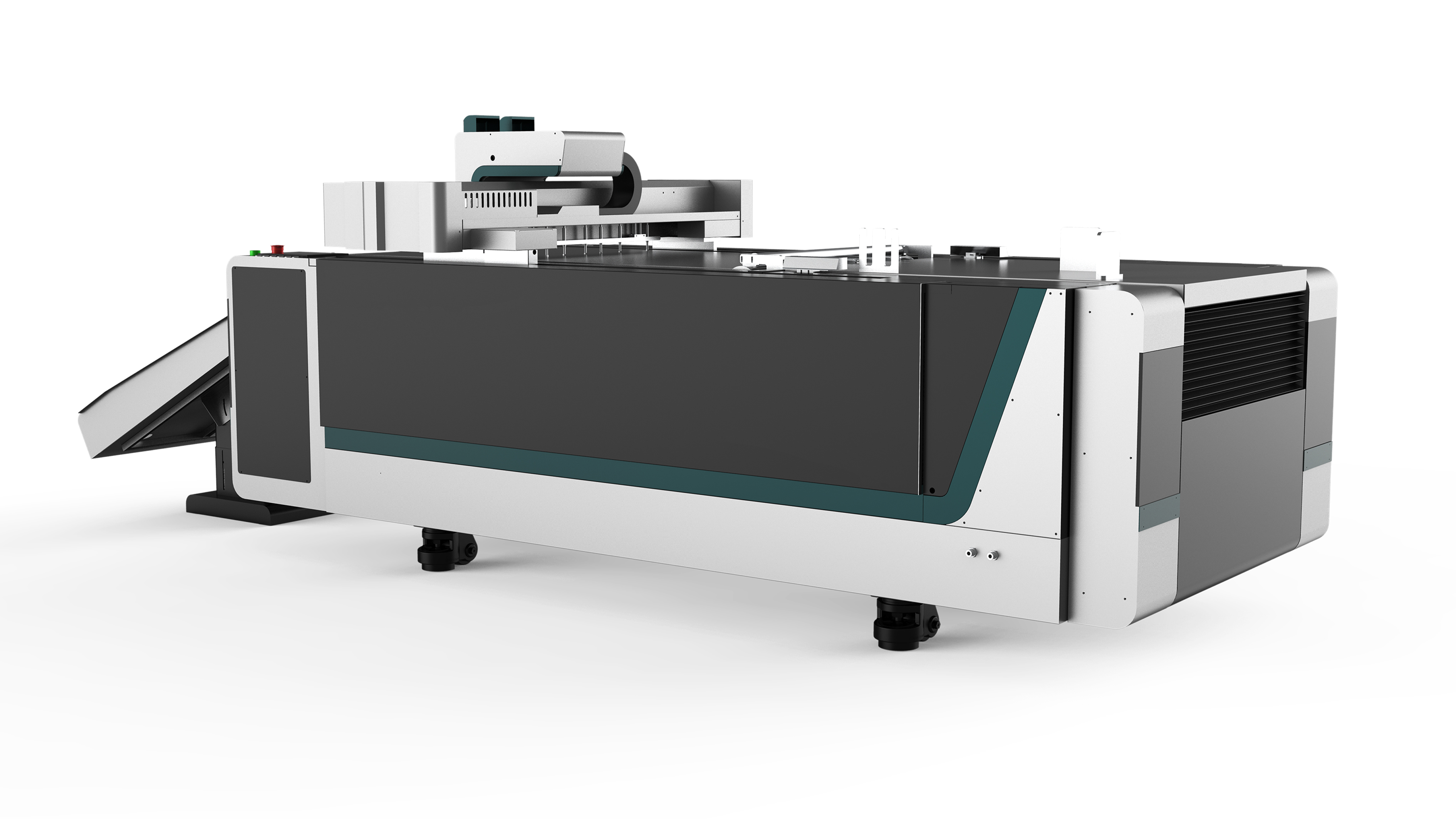

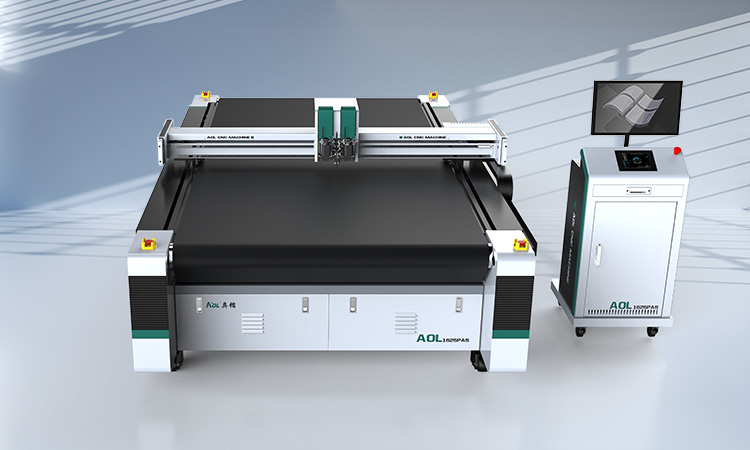

The digital cutting machine consists of a flat table area and a set of cutting, milling and scribing tools mounted on a positioning arm that moves the cutting tools in two dimensions. The material is placed on the table surface and the cutter follows a programmed path through the material, cutting out pre-programmed shapes.

Digital cutting realizes large-format custom cutting

The biggest advantage of digital cutting is that there are no molds of a specific shape, which ensures shorter turnaround times compared to die-cutters as there is no need to switch between mold shapes, reducing overall production time. Additionally, there are no costs associated with the manufacture and use of molds, making the process more cost-effective. Digital cutting is especially suited for large format cutting jobs and rapid prototyping applications.

Computer-controlled digital flatbed or conveyor belt cutters can easily combine registration mark detection on the material with on-the-fly control of cut shapes, making digital cutters very attractive for highly customizable automated manufacturing processes.

The growing popularity of digital cutting machines has led manufacturers to offer a wide range of digital cutting solutions in the market, from large industrial machines that can handle panels of a few square meters to hobby-grade cutting machines for home use.

Advantages and uses of digital cutting machines

A particular type of digital cutting technique that has become popular in recent years is blade cutting. This process is very similar to die-cutting. He uses a blade to cut, and uses computer software to upload the material pattern to be cut. There is no need to make a mold separately, which saves a lot of mold cost and time.

This kind of cutting equipment can be equipped with a variety of knives and drawing pen tools such as vibrating knife, drag knife, circular knife (optional active wheel knife, pneumatic circular knife), etc., depending on the different needs of different materials, it can realize things such as writing and drawing lines, dotted lines, etc. Cutting, half cutting, full cutting and other functions, can cut and paint various flexible materials such as single/multi-layer glass fiber, glass fiber cotton, prepreg, carbon fiber, carbon fiber felt, aramid fiber, etc.

Some leading manufacturers of digital cutting equipment combine mechanical and digital cutting in one system, allowing end users to benefit from the advantages of these methods.

For more information, please consult:

Email: info@aolcnc.com

Phone: +86-0531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://www.aolcnc.com/