In today's fast-growing social rhythm, traditional cutting methods have given way to advanced technology, and one of the most promising innovations is the digital and automated single-layer CNC cutting machine. This cutting-edge equipment has revolutionized the cutting process, enabling industries to streamline operations, minimize waste, and achieve unparalleled precision on a wide variety of materials. Continue reading this article, which will take you to learn more about related equipment!

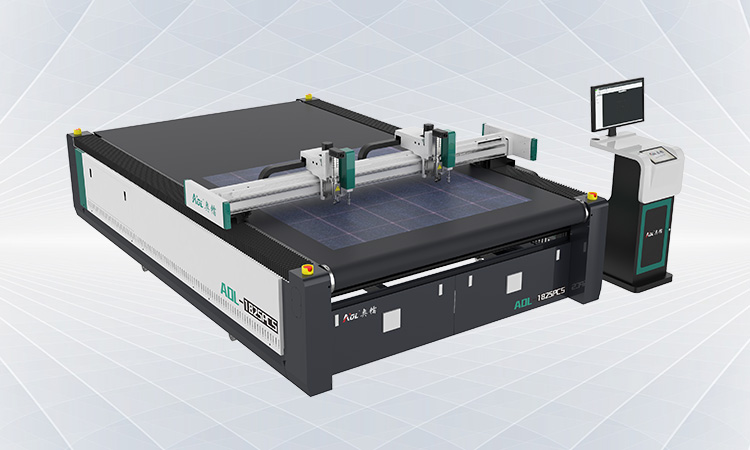

Digitalized, automated single-ply cutting is the answer to these new production realities. AOL's single-ply cutter is the perfect cutting tool for automating production workflows, giving manufacturers the flexibility and profitability they so desperately need. Intelligent automation capabilities, optical solutions and software tools make it easier for them to optimize resources, monitor material usage and support staff so they can focus on other activities that add greater value to the business. With digital single-layer cutting technology, manufacturers can increase productivity while expanding capacity. With very economical, efficient and scalable on-demand production, manufacturers can easily accept last-minute orders and meet short lead times. They can handle peak demand with ease and confidence.

Features and Functions of CNC Single Layer Cutting Machine:

High-Precision Cutting: The advanced digital control of the single-ply CNC cutting machine ensures precise cutting of complex shapes and designs, even from the most complex materials. The machine is capable of handling single layers, which reduces the risk of errors and guarantees excellent product quality.

Automation and material optimization: Automation is the cornerstone of this technology. Once programmed, the machine operates autonomously, reducing the need for ongoing human intervention. This simplifies the production process, minimizes downtime and maximizes material utilization.

Versatility: From textiles and fabrics to plastics, foams, and composites, single-ply CNC cutting machines can handle a wide variety of materials. Its adaptability makes it an invaluable tool in industries ranging from fashion and automotive to aerospace and furniture.

Advantages of digitized and automated single layer CNC cutting machine:

Increased Efficiency: By eliminating the need to cut multiple layers, the machine significantly reduces processing time. Manufacturers can get more done in less time, increasing overall productivity and meeting tighter deadlines.

Reduce material waste: The single layer CNC cutting machine minimizes waste generation through precise cutting and material optimization. This benefit can translate into cost savings and positive environmental impact for the company.

Cost Effective: Despite the large initial investment, single layer CNC cutting machines prove to be cost effective in the long run. Over time, lower labor costs, less material waste, and increased production yields will contribute to significant cost savings.

High-quality cuts: High levels of precision and automation ensure consistent and reliable results. Manufacturers can maintain stringent quality control measures resulting in products of unparalleled quality.

The AOL cutter combines tremendous versatility in one machine, allowing users a whole new level of flexibility in their production workflow. They can process demanding textiles, complex patterns and diverse shapes without difficulty. AOL's tailoring technology enables the apparel industry to produce custom garments in small batches on demand as cost-effectively as mass production. It processes and processes multiple orders faster while saving time and materials with efficient nesting capabilities. Parts can be very closely nested and close to the edge of the material.

Digitally automated single-ply CNC cutting machines represent a transformative advance in manufacturing technology. By leveraging precision, automation and material optimization, these machines have the potential to revolutionize various industries. By increasing efficiency, reducing waste and improving product quality, companies can remain competitive in an ever-changing global marketplace. As technology continues to advance, we can expect more sophisticated iterations of CNC cutting machines, opening up new possibilities and applications in manufacturing.

If there is anything else you want to know, please contact us in the following ways:

E-mail: info@aolcnc.com

whatsapp:+86 18560162709