1. What is a digital cutting system?

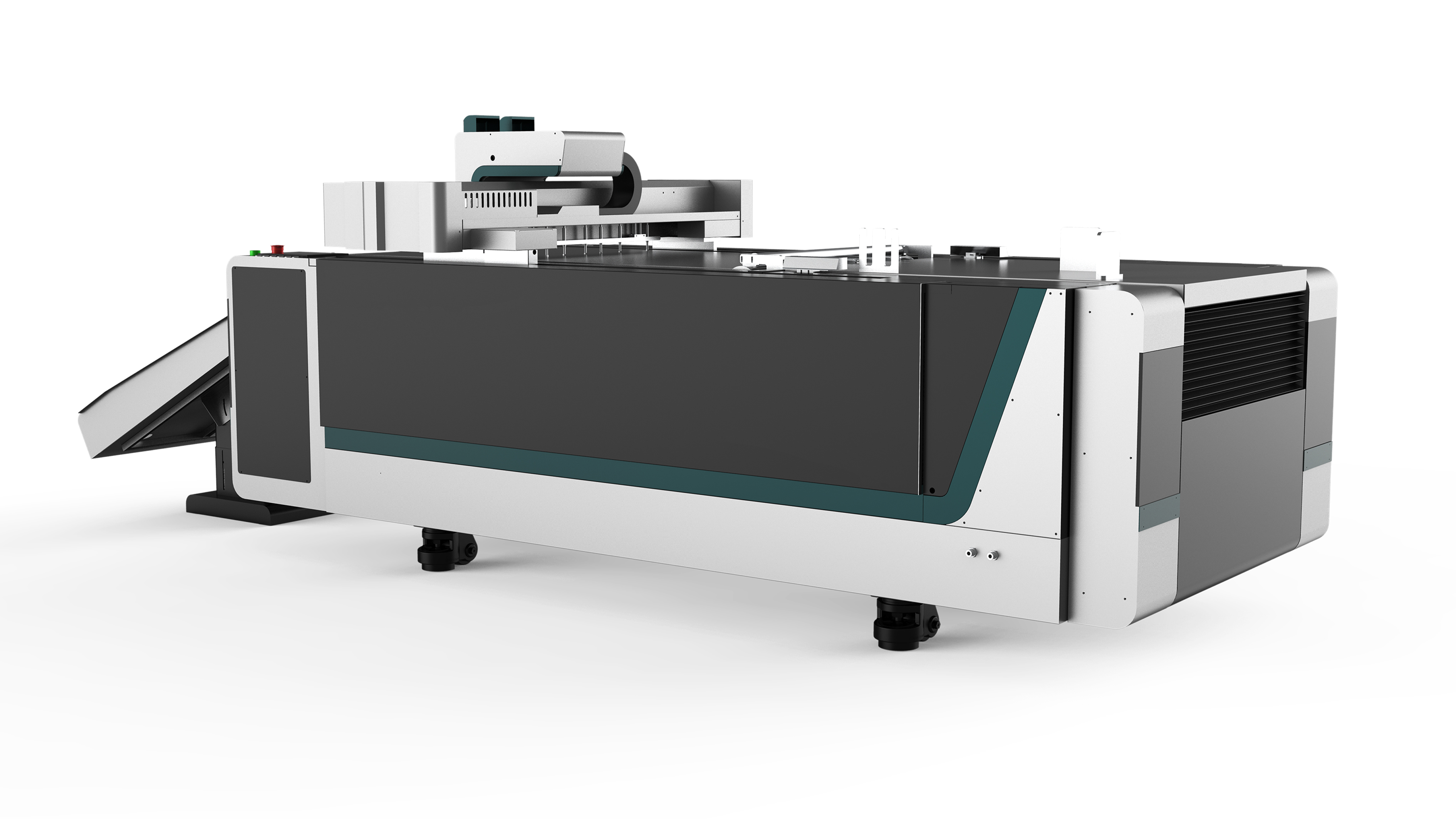

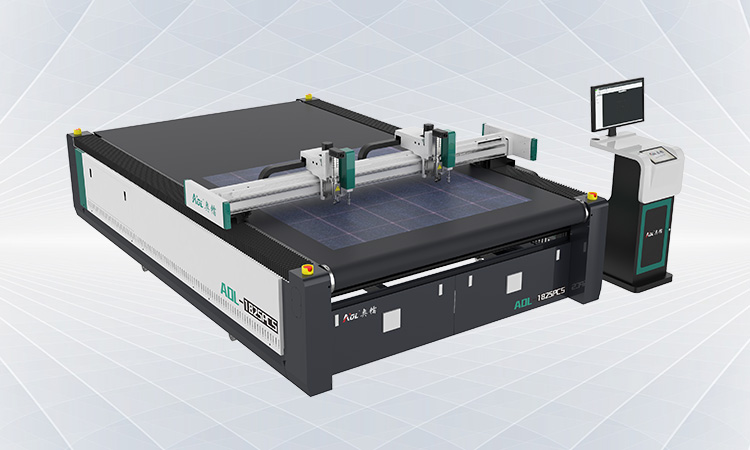

A digital cutting system is a machine for precision cutting, creasing and milling of various materials including paper, cardboard, fabric, leather, foam and plastic. It utilizes computer-controlled technology to precisely cut intricate shapes, designs and patterns.

2. How does the digital cutting system work?

A digital cutting system typically consists of a cutting table, cutting head or tool, and computer software. The cutting head or tool is controlled by computer software that sends commands to the machine to perform the desired cut. Depending on the material and application, the machine can use different cutting techniques such as oscillating blades, drag knives, creasing or scribing pens.

3. What are the advantages of using a digital cutting system?

Digital cutting systems offer several advantages over traditional manual cutting methods:

Precision: Digital cutting systems can achieve high levels of precision and consistency, ensuring precise cuts and intricate designs.

Versatility: These systems can handle a wide variety of materials and thicknesses, making them suitable for a variety of industries and applications.

Efficiency: Compared with manual cutting methods, the automated cutting process saves time and labor, increases productivity and reduces production costs.

Flexibility: Digital cutting systems can easily switch between different cutting designs and patterns, enabling customization and rapid prototyping.

Reduced waste: Precise cutting capabilities minimize material waste, optimize material usage and reduce costs.

Integration with design software: These systems can be seamlessly integrated with design software, allowing direct transfer of cutting patterns and designs, streamlining workflow.

4. Which industries can benefit from digital cutting systems?

Digital cutting systems are widely used in various industries, including:

Printing and Packaging: They can cut and create materials for packaging, displays, labels and signage.

Textiles and Apparel: These systems cut fabric, leather, and other materials used in apparel production, upholstery, and accessories.

Automotive and Aerospace: They are used to cut gaskets, interior components, insulation and composites.

Furniture and Upholstery: Digital cutting systems can cut foam, wood and other materials for furniture manufacturing and upholstery applications.

Industrial Manufacturing: They are used to cut materials used in industrial applications such as gaskets, seals, insulation and composites.

Education and Prototyping: Digital cutting systems are used in educational institutions for teaching purposes and in product development for rapid prototyping.

5. Is the digital cutting system easy to operate?

The digital cutting system is designed to be user-friendly and intuitive. The accompanying software usually provides a user-friendly interface and design tools to create and manipulate cutting patterns. While there can be a learning curve to mastering the software and optimizing cutting parameters, manufacturers often provide training and support to help users become proficient with the system.

6. What kind of maintenance does the digital cutting system need?

Regular maintenance is essential to ensure optimal performance and longevity of your digital cutting system. This may include cleaning the cutting table, changing or sharpening cutting tools, checking and calibrating machinery, and checking and lubricating mechanical parts. Manufacturers often provide maintenance guidelines and schedules to help users keep their machines in top condition.

It is worth noting that specific features, functionality and maintenance requirements may vary between different digital cutting system manufacturers and models.

For more information, please contact us. We will provide professional answers.