The rubber gasket has the characteristics of high temperature resistance, low temperature resistance, ozone resistance, aging resistance, corrosion resistance, oil resistance, etc. It can produce sealing gaskets of various shapes, including solid circular gaskets or square gaskets and other shapes. It is widely used in auto parts, household appliances, mechanical parts, LED photoelectric, electronic toys and other industries, and can play the role of gasket, seal, buffer, etc.

No matter which type of gasket is metal or nonmetal, although the material is different, the processing method is the same, and all of them need to be made by cutting, stamping or cutting. What I want to discuss with you today is the cutting and cutting of rubber pads. Let us know how the sealing gasket cutting machine brings us value.

At present, one of the equipment with high usage rate for cutting rubber gaskets is the punch press. The cutting process of this equipment needs to calculate the size of the gasket, and then make the corresponding mold. Then, open the mold according to the size of the gasket, put the raw materials of the gasket into the mold, use the equipment to punch, apply pressure, and then process the gasket. Through the above introduction, it is not difficult to find that the complicated process is the short plate of the rubber gasket cut by the punch. A small customization requires a lot of time to process with the mold, and the price of the mold is naturally not cheap, so processing requires not only a lot of labor, but also additional costs. If we do small batch production customization, we won't make any money at all. Therefore, the cutting of rubber gaskets by punch presses has greatly limited the development and production speed. So how can we say goodbye to the cutting method of die stamping and cut the sealing gasket more efficiently? Let's talk about the convenience that the rubber gasket cutting machine can bring us. Let's watch a video to understand!

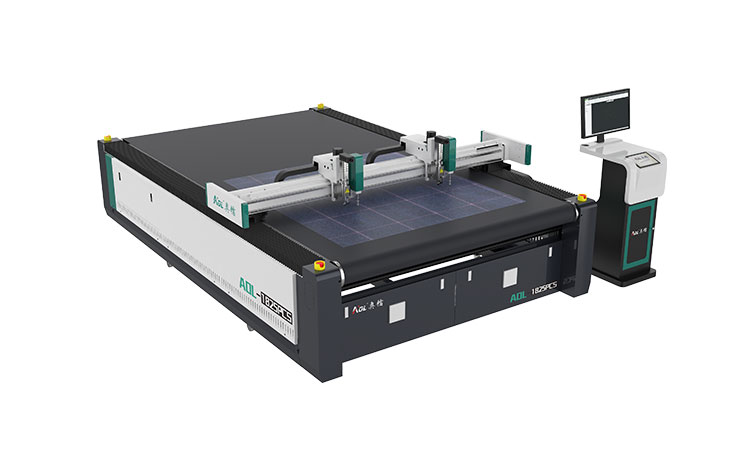

The rubber gasket cutting machine does not need to make plates, but only needs to import the data into the system to identify and cut materials. The automation of this step directly saves a lot of time and cost.

Super nesting software supplement, intelligent and accurate typesetting, no need for manual nesting, after a large number of tests, the use of automatic cutting machine will save more than 10% of materials than manual. Based on this data, you can calculate how much you can save in a year.

The cutting is more accurate. The requirements for rubber gaskets are very high in this respect. Errors will not match, which affects many aspects. During the cutting process of the manual punch, there is a large probability of deviation. The machine can reduce the error to the minimum after being supplemented by the software system.

The machine is intelligent and automatic, and the operation is very simple. It requires few workers and can work for 24 hours continuously to get rid of the problems of high labor costs and difficult recruitment.

The above is my introduction to the rubber gasket cutting machine today and my analysis of the disadvantages of manual cutting. I believe that you in front of the screen can quickly understand the content of the article. In addition to the rubber gasket, our machine can also cut other flexible materials. Specific materials can be communicated with me again. The emergence of AOL equipment is to make cutting simple!

For more information, please consult:

Email: info@aolcnc.com

Phone: +86-0531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://www.aolcnc.com/