Dermal leather is made of animal skin, which is conceptually opposite to artificial leather made of chemical fiber materials. The dermis in the market generally refers to the first layer of leather and the second layer of leather. The industry products that are often seen in life are sofa, leather shoes, bags, leather clothes, ball products, car seat covers and other places. In order to meet various production needs, it has promoted the transformation of cutting methods. The development of leather CNC cutting machine meets the needs of the current market, simplifies the cutting program, and reduces the cost of labor and raw materials!

The leather materials used in different industries are also different. Next, let me tell you what materials are commonly used in the industry? Different uses of leather lead to different types of leather. For example, cow leather with fine surface and high strength is most suitable for making leather shoes; Sheepskin leather is light, thin and soft, which is the ideal fabric for leather clothing; Pigskin leather has good air permeability and water vapor permeability. These leather types need to go through the material cutting process before being made into finished products. At present, in addition to manual cutting, intelligent cutting is commonly used. Some time ago, a customer contacted us to ask whether our cutting equipment can cut their leather. Our answer is yes! It is understood that they used to cut manually, which is slow, labor cost is very high and raw materials are wasted. The following points are based on our understanding of some problems in manual cutting:

1. The efficiency of manual defect avoidance calculation and typesetting is too low

2. Manual painting, low cutting efficiency and non-standard

3. The demand for typesetting is diversified, and the order requirements are getting higher and higher

4. There are many kinds of leather and cutting pieces, and the manual management is confused

5. The utilization rate of raw materials for manual nesting is too low

6. High technical requirements for cutting staff, difficult recruitment and high salary

7. Complicated leather cutting, punching and marking processes

According to some disadvantages of manual cutting, we briefly introduced leather materials used in various industries and recommended models for different industries. If the materials are special or the size has requirements, we support customization to meet a variety of personalized needs. Read on to learn more! You can see how the leather cutting equipment operates before knowing:

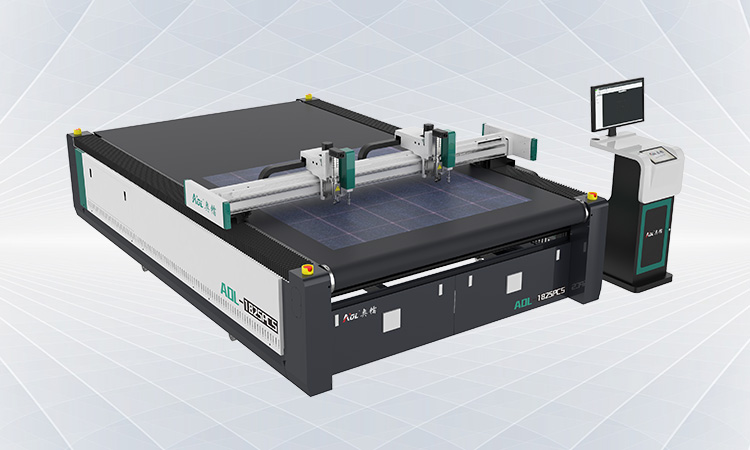

Most of the ball products are made of PU synthetic leather. PU synthetic leather is a new type of material used to replace traditional natural cow leather products. Basketball made of PU synthetic leather has the advantages of waterproof, wear-resistant, mildew resistant, and suitable for indoor and outdoor dual-use It is recommended to use intelligent numerical control cutting machine when cutting PU synthetic leather, which can effectively avoid the drawbacks and environmental protection problems caused by other cutting equipment and will not damage the nature of the material itself, and is favored by many manufacturers. Here we recommend using AOL-1625PCS cutting equipment plus large industrial cameras for material identification. We recommend selecting vibrating knife as the cutter head and z026b as the cutter head for perfect cutting!

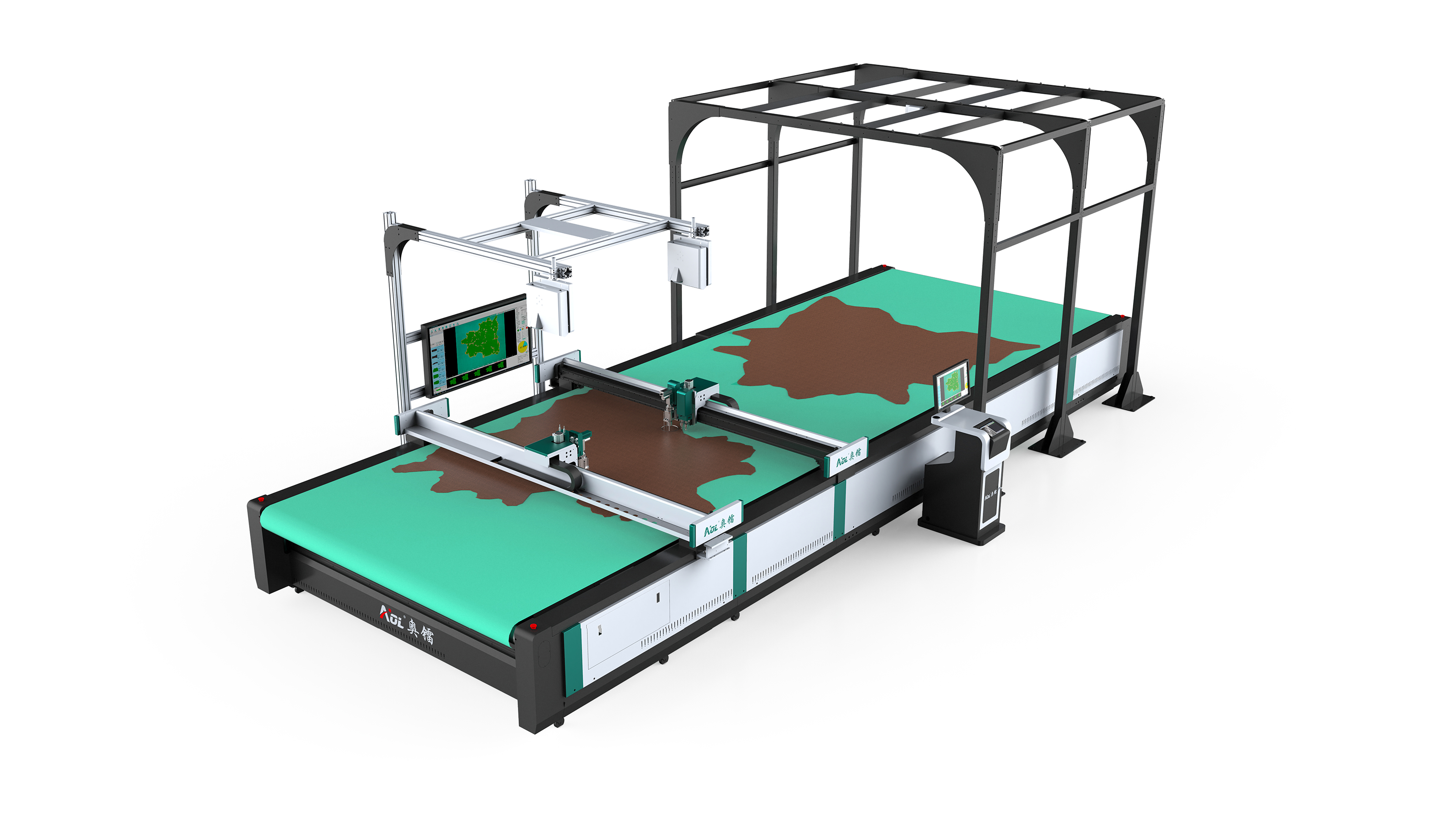

The leather raw materials used in bags, sofas and car seats are mostly cow leather. The leather surface is undamaged, the grain is neat, and the texture is soft and good. Of course, pig skin and sheepskin are also common finished materials. Because the materials used in bags and sofas are relatively large, AOL-2535PCSII cutting equipment is recommended, and is a model specially used for cutting leather, It can identify and cut multiple pieces of leather in assembly line, not only cutting leather materials, but also cutting other flexible materials. It can flexibly adapt to production needs.

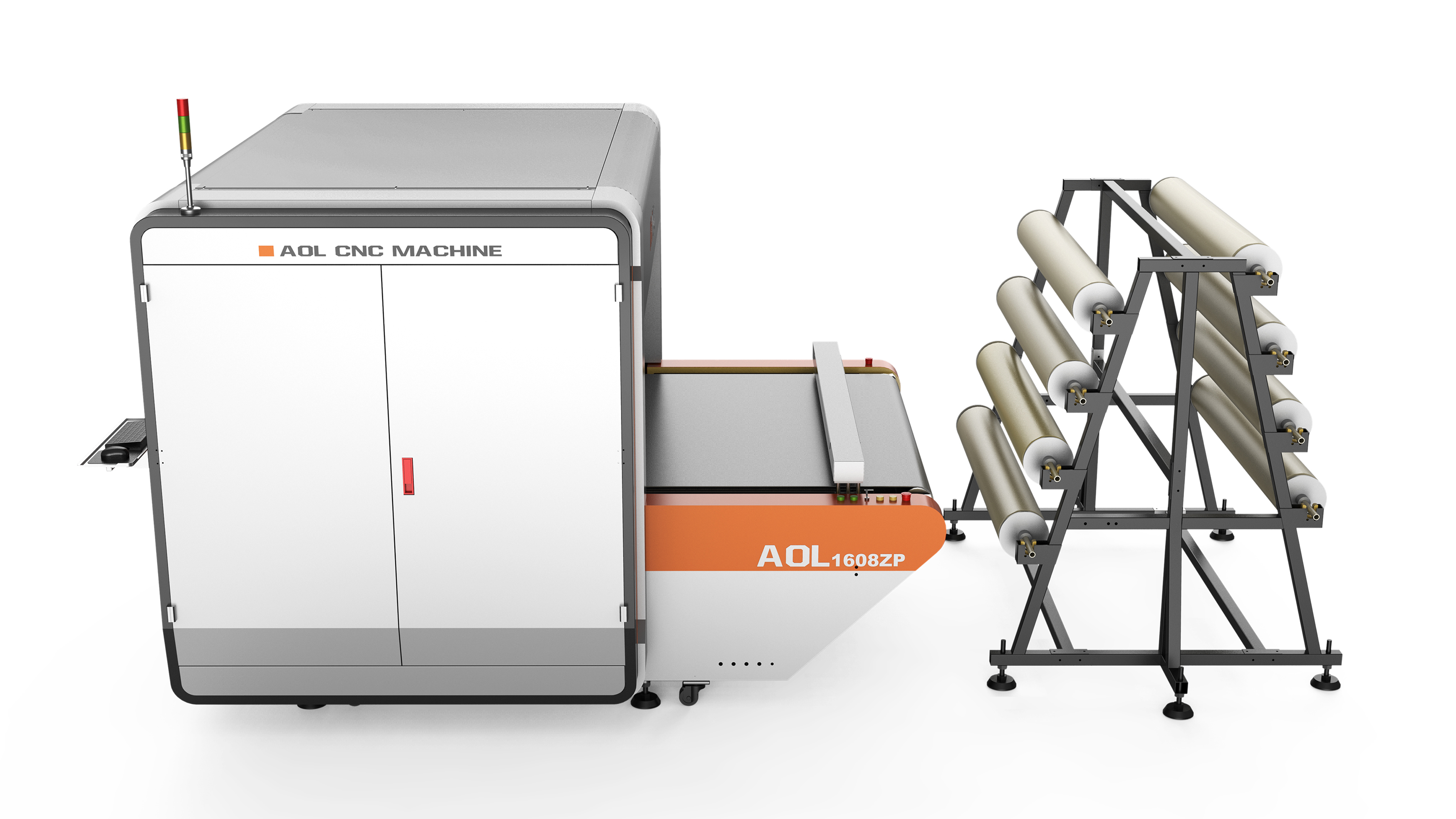

The leather shoes are mostly made of cowhide and sheepskin, as well as crocodile leather and pig leather. The leather shoes made of cowhide are of the best quality. Most of the fabrics of the shoes are made of cow yellow leather, and the leather surface is smooth and flat. We mostly use AOL-1608ZP double cantilever cutting machine to cut the leather shoes. The efficiency of this cutting machine is higher than that of other models!

Many people will question why they choose intelligent CNC cutting equipment after reading this? Why AOL? What are the advantages? Now let me answer all kinds of questions one by one.

Why choose intelligent CNC cutting equipment?

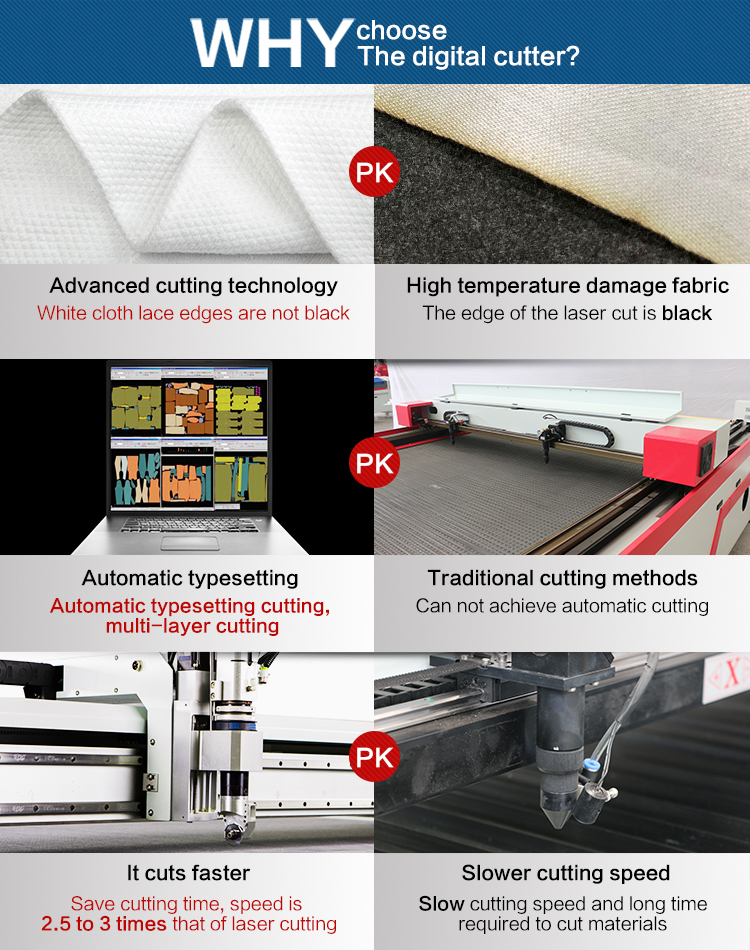

In daily life, in addition to manual cutting, there are laser cutting equipment. Manual cutting is not mentioned here. Laser cutting equipment is much cheaper than numerical control cutting equipment. Many businesses will give priority to laser cutting equipment, but many people will regret after buying it. Leather materials are very expensive. Laser is a thermal cutting processing equipment, which will lead to the burning and yellowing of materials during the cutting process, It is not only a waste of raw materials, but also requires secondary processing. It is recommended to use numerical control cutting equipment because this type of equipment uses a blade for cutting, which belongs to the cold cutting mode. This equipment not only solves the problem of burning and yellowing in the laser cutting process, but also solves the problem of high manual cutting costs. One machine can replace the workload of 3-5 workers and one person can operate multiple equipment at the same time, This is why we recommend you to use CNC vibrating knife cutting equipment!

Why choose AOL and what are its advantages?

First of all, let's introduce AOL CNC Equipment Co., Ltd., which has 14 years of industry experience. We have provided services to more than 8000 customers around the world and obtained satisfactory evaluations. We have many long-term stable cooperation customers. We provide many customers with personalized industrial material cutting solutions.

Our cutting equipment has the following advantages, please understand:

1. Industrial vision system is selected to quickly scan leather material and automatically identify contour and defects

2.AOLCUT self-developed software, one-click import, automatic cutting, order management

3. New super discharge engine, discharge speed is increased by more than five times, material utilization rate is increased by more than 10%

4. According to the classification of leather material, it supports zoning classification and directional discharge cutting, and supports a variety of discharge rules

5. The transmission system adopts the German pinion and rack transmission, the accuracy is ±0.1mm

6. Use Japanese Panasonic servo system to improve the production efficiency by more than three times

7.AOL a variety of tool options, cutting and punching marks once completed

8. Unique multi-partition technology increases the adsorption capacity by more than 5 times

9. This model has won 5 patent technology certifications at home and abroad

Aol CNC is your best choice!More cheap high quality cutting machine waiting for you https://www.aolcnc.com/

For more videos about AOL, please click:https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA?view_as=subscriber

AOL facebook: https://www.facebook.com/aolcuttingmachine

Contact Email:info@aolcnc.com