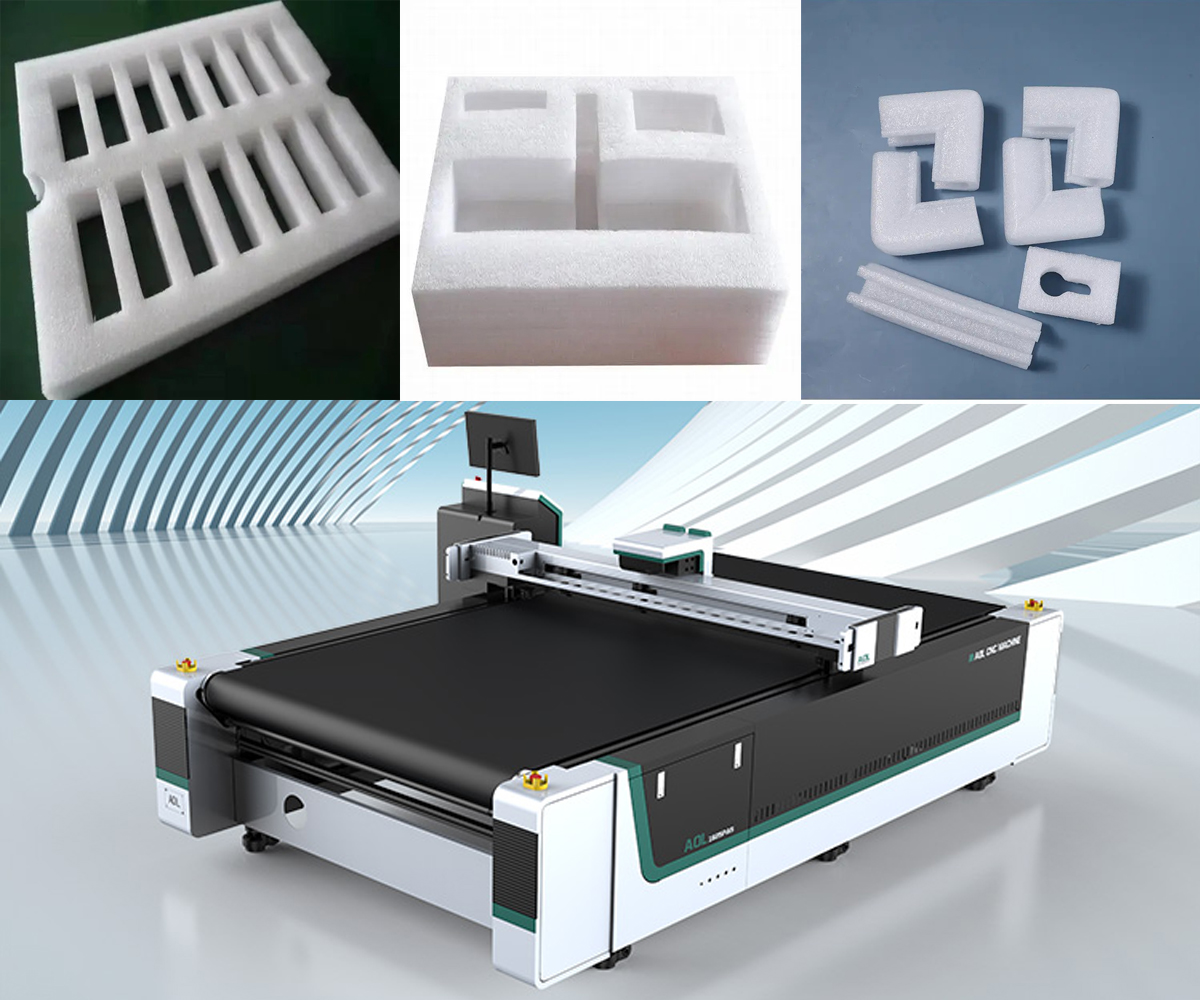

EPE foam is a new type of environmentally friendly packaging material with high-strength cushioning and shock resistance. It's soft, lightweight, and incredibly strong. It can eliminate and disperse external impact by bending to achieve the effect of cushioning. It solves the shortcomings of traditional styrofoam such as fragility, deformation, and poor recovery. Therefore, the application of EPE foam lining is more and more extensive. Glass bottles such as wine bottles are very fragile. In addition, in order to improve the quality of packaging, many of them now use EPE foam packaging.

There are generally many shapes of bottles, so there are many types of pearl cotton holders required. Our CNC foam cutting machines are ideal for diverse and customized production.

The traditional production method of EPE foam support is to make it through a mold through a hydraulic press. First, make a mold of the corresponding size and shape according to the product. Then install the die die on the hydraulic cutting machine. Put the pearl cotton sheet under the knife mold. Start the hydraulic press and press down, and the knife die will press and cut the EPE foam to obtain the product. The efficiency of this processing method is very fast. But no matter how much the processing volume is, even if it is proofing, it is necessary to make a mold first. It takes a few days to make a mold, and the mold may need to be modified during proofing, so this process takes a long time. The cost of cutting dies is not cheap. Therefore, it costs a lot of money to make a knife mold every year. For thicker EPE foams, the die cutting process compresses the foam. The length of the cutting edge is generally not more than 30mm. For foam boards around 70mm, 70mm will be compressed to within 30mm during press cutting. So at this time, the cut surface will have obvious curvature. The center of the pressure surface will be depressed.

Our pearl cotton cutting machine is CNC cutting machine. Therefore, it is very simple and convenient to carry out proofing, modification and customized production. Just need to make CAD drawings according to the size and shape of the bottle. Then import the vibrating knife cutting machine through the computer software for automatic cutting. Therefore, samples can be quickly produced and provided to customers, thereby reducing the time for proofing and modification. Easier to get orders from customers. The production process of our foam cnc cutting machine saves labor. The foam board is automatically cut on the machine table, and workers can carry out packaging work at this time.

Foam board cutters can also be equipped with milling cutters. Some foam mounts have internal grooves. For example, a 50mm thick foam board has a 30mm inner groove in some places. The traditional processing method is to cut two layers of pearl cotton of 30mm and 20mm and paste them together with glue. But glue has a bad smell and is not good for health, so some products are not allowed to use glue. A combination of milling cutters and cutters can solve this problem. Milling cutters are used to carve impenetrable inner grooves to a controllable depth. After the engraving is completed, the cutting knife automatically cuts the outer contour. This process is also done automatically under computer control.

The cutter of the foam board cutting machine is a high-frequency vibrating cutter. When cutting, the blade vibrates up and down at high frequency, which reduces the cutting resistance and improves the cutting speed. Vibrating knife cutting machine can cut 100mm pearl cotton. Moreover, the blade is vertical, and the cutting surface is also completely vertical, so there will be no problem with the radian of the punch.

If you want to know more about performance issues, please leave a message , we will have a professional staff contact you.