From apparel to knitting, packaging, graphics, leather and textile industries, large manufacturing companies are using CNC knife cutting machines for all types of materials involving tasks like cutting, routing, creasing, scribing, plotting, hole punching and more.

Also known as a vinyl cutter or sign cutter, this machine's distinguishing feature is that it can cut material by pressing the tool into it.

Unlike other tools such as rotary tools, laser heat, or water jet cutters, CNC knife cutters transfer no heat as they cut material. Thus, the machine's knives and blades remain clean, simple and preserved in different environments.

Introduction to common knives:

CNC knife cutters, also known as digital cutters, are helpful in processing various materials with multiple cutting heads.

With multiple cutting heads, you can ensure that the machine is configured to meet your unique business needs.

When combined with different cutting techniques, the machine offers versatility by offering a milling spindle and two knives which can be tangential, oscillating drag, vinyl or a combination thereof.

Drag Knife: This knife is used to cut different materials with the speed and precision of a CNC router. Drag knife cuts a variety of materials to a depth of 1/4 inch. The tip of the blade is slightly offset from the center of the chuck so that the knife can rotate in the direction the CNC machine is moving.

From the utility knife blade in the block to the blade made of hardened alloy, this knife is custom-made. Drag knives can be easily installed and replaced, but the only trouble you may face is abrasive. More material is thicker; the blade may create more friction, pushing the material away from its position.

Oscillating Knife: This type of knife option is considered one of the most important options for businesses that help process flexible materials such as packaging foam, foam core, alligator foam, corrugated plastic, and cardboard.

The oscillating knife cuts through materials with ease, with clean, fine edges and virtually 0% chance of galling.

The oscillating knife system ensures accurate, even cuts on thicker materials without overcutting. Oscillating knives are versatile in nature, capable of cutting a variety of materials while maintaining minute details and curves.

Creasing wheel: used for creasing of carton packaging materials.

Due to its hardness, the creasing wheel resists abrasive compounds and reduces friction.

Serrated tools, on the other hand, add enough stress when cutting to cause deformations such as stretching and tearing.

Half cutting knife: The cutting knife is a special tool specially used for cutting vinyl and self-adhesive. The depth of cut of the tool is controlled by downward depth pressure. This type of knife can be easily installed without removing the spindle.

It is an efficient plotter for creating different patterns on materials. With the help of the Kiss Cutter, the cutting process becomes easier and more efficient.

What industries does CNC knife cutting machine serve?

Leather industry:

Processing leather is now economical. Unleash your creativity with a CNC knife cutter. This digital cutting system increases productivity and flexibility in the leather industry.

Now you can process leather, soles, linings and uppers with optimum precision.

Fashion and Apparel Industry:

Fabric cutting machines have been helping the world's leading apparel manufacturing companies maximize quality and profitability and bring products to market faster, smarter and better.

Graphics Industry:

Whether cutting complex graphics or banners, with the help of advanced digital cutting machines, cutting and routing is easier than traditional techniques.

Cutting solutions from CNC knife cutting machine technology are engineered to meet your needs and deliver the quality and productivity you expect.

Packaging Industry:

Packaging plays an important role in protecting products and ensuring their safe delivery. A good packaging carton, folding box, honeycomb box, cardboard folder, etc., is created with a versatile and easy-to-use digital CNC knife cutting, which helps to increase the company's productivity and efficiency while reducing production costs, downtime , and waste. CNC machines help to transform your ideas into reality and present proposed designs within seconds.

Textile industry:

No matter what type of textile you need to cut, a CNC knife cutting machine can help you do it faster and more efficiently.

Apparel, upholstery, airbags, flags, sunshades/umbrellas, automotive and aircraft seats are some of the applications in this industry.

Honeycomb Paperboard Industry:

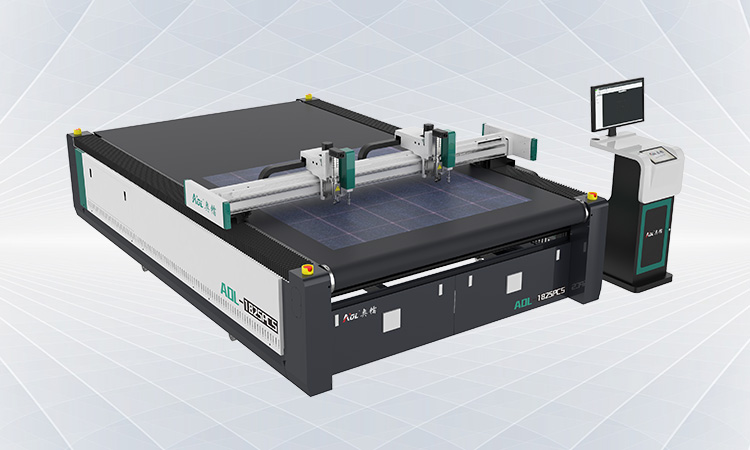

AOL CNC knife cutting machines help automate the design and cutting process to increase productivity and minimize labor.

CNC knife cutting machines can produce beautiful designs, maintaining the correspondence of designs with the highest precision.

Suitable for cutting complex patterns on honeycomb paperboard while maintaining high precision cutting. Compared with the laser cutter, the edge of the vibrating knife cutter is smooth and clean.

There is neither smoke nor any odor when cutting. User friendliness is one of the best features of this machine.

Composites industry:

Create perfect products with CNC knife cutting machines. This highly advanced machine gives you a modular, flexible, cost-effective and scalable cutting system for processing a wide variety of materials with impeccable precision.

It provides robust and tailor-made solutions for industrial applications such as defense, functional textiles, wind turbine rotor blades, aircraft and automotive components.

Advantages of CNC blade cutting machine:

High precision:

Imported accessories are used to ensure the cutting precision of the machine.

This advanced tool performs at a higher speed, cutting 5-8 times faster. Whether you're cutting composites, canvas, laminates, textiles, CNC cutting machines deliver unprecedented speed, consistency and reliability.

This model is widely used in clothing industry, shoemaking industry, clothing fashion fabric industry, automotive interior industry, luggage industry, packaging industry, decoration industry, electronics industry, composite material industry, etc.

The automatic features of this machine reduce the labor and time required to perform tasks. It also increases efficiency and simplifies tasks that once ran haphazardly.

Environmentally friendly:

Unlike CNC laser machines and milling machines, CNC knife cutting machines are environmentally friendly.

It cuts materials without diffusing harmful gases or transferring heat, whereas other tools use rotary tools, laser heat, or water jets to cut materials. Therefore, CNC tools are safe to use and easy to maintain in different environments.

This digital cutting machine operates according to a digitally programmed toolpath. It cuts material by moving only the knife and sticking the material to the machine or by moving the knife and material at the same time.

Perfect Cut Edges:

The CNC knife cutter produces smooth cut edges without any burrs. Unlike laser machines or milling machines, knife cutters cut through materials without burning effects or burnt yellow edges.

There is absolutely no need to polish the cut edges as every cut is perfect.

The machine also allows cutting square corners, beveled edges, half circles and segmented arcs with great precision. CNC knife cutting machines increase your ability to innovate and convince customers with extraordinary solutions.

It helps increase efficiency, shorten cycle times and reduce material waste.

Disadvantages of CNC blade cutting machine:

Not suitable for hard materials:

only suitable for soft to semi-hard materials, CNC knife cutting machines cannot process heavy materials.

Cutting low-ductility and high-toughness materials will mean compromising the smoothness of the oscillating blade.

The CNC knife cutting machine is also suitable for cutting large textiles. It can be equipped with a feeding rack and adopts automatic feeding without manual feeding.

This advanced machine comes in different sizes and types of knives to handle different materials and thicknesses.

AOL CNC Cutting Equipment will dramatically increase the demand for CNC machines in shorter lead times and higher productivity. CNC knife cutting machines exponentially increase your capabilities by automatically, precisely and efficiently processing a wide variety of flexible and foldable materials.

If you would like to learn more about our products and services, please don't hesitate to contact us. Our friendly customer service team is available to answer any questions you may have and provide you with more information. You can reach us by phone, email, or through our website. We look forward to hearing from you!