What is a drag knife and how does it work?

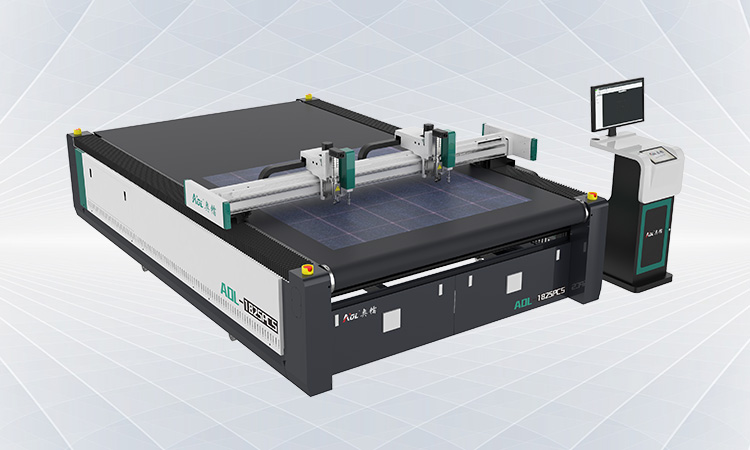

If you know anything about CNC machine tools, you may have heard of drag tools. A drag knife is a cutting tool that drags the blade across a flat surface or material. In this article, we’ll explore the concepts and functions of a drag knife, the types available on the market, and how to choose the right knife for your specific needs.

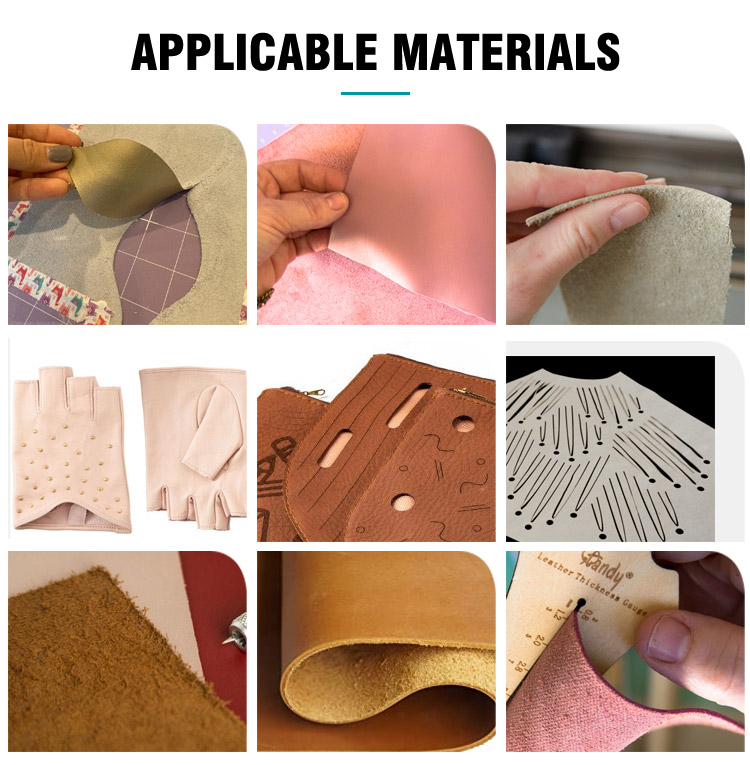

A drag knife is a cutting tool that operates by dragging the blade across a flat surface or material, unlike other types of knives that cut by rotating. Drag knives are typically used for cutting materials that require a sharper blade, such as vinyl, leather, fabric, and paper. The blade is mounted on the tool holder of the CNC machine and moves along the cut material in the designed shape.

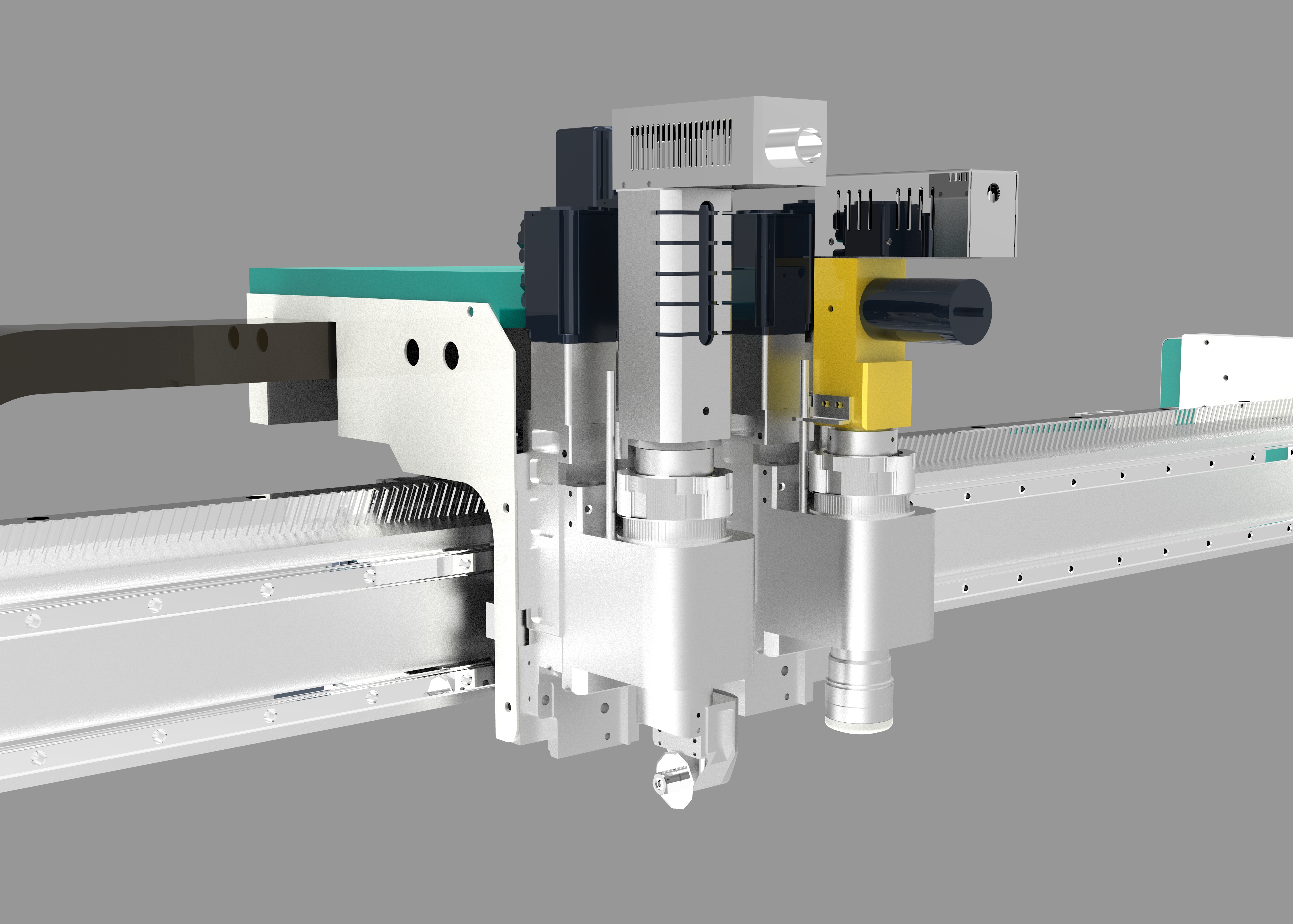

The blade is mounted on a swivel base and can swivel, tilt and pivot. As the edge moves along the material being cut, the rotating base will allow it to adjust the angle and depth of the cut, ensuring it maintains a consistent angle as it cuts through the material. The blade is usually spring-loaded so it can adjust to the thickness of the material, maintaining constant cutting pressure during processing.

Application of drag tool in CNC machine tools

Drag tools are widely used in CNC machine tools for a variety of applications. In the automotive industry, drag knives are used to cut gaskets, stickers, and seat leather coverings. In the apparel industry, drag knives are used to cut fabrics of different textures, such as denim and silk. In the sign industry, drag knives are used to cut vinyl to create signs and decals. Other applications for drag knives include cutting cardboard, paper, rubber, foam and other materials.

There are many types of drag knives on the market, each with unique features and benefits. The most common types are fixed blade knives, rotating blade knives, and oscillating blade knives. Fixed blade knives have a fixed blade that moves up and down and are best for cutting simple shapes. Rotary blade knives, on the other hand, have rotating blades that can move in any direction, making them ideal for intricate designs. Oscillating knives have a forward and backward motion that allows them to cut thicker materials such as foam, rubber, and plastic.

Choose the right drag tool for your CNC machine

When choosing a drag tool for your CNC machine, you need to consider factors such as the material you are cutting, the thickness of the material, and the complexity of the design. Additionally, it is crucial to choose cutting equipment that is easy to install and maintain. It is crucial to choose a reputable and reliable manufacturer or supplier to ensure you are getting a high-quality product that meets your needs and expectations.

Advantages of using a drag knife to cut materials

One of the main advantages of using a drag knife is its precision. The blade can cut complex patterns and shapes with high precision, making it an ideal tool for cutting designs for stickers, decals and other decorative applications. Drag knives are versatile and can easily cut through a variety of materials, both thick and thin.

Another benefit of using a drag knife is that it cuts quickly. The blade cuts extremely quickly, allowing for fast and efficient production runs. Additionally, drag knives produce clean cuts with smooth edges, reducing the need for post-processing and saving time during the production process.

Limitations and Challenges of Using a Drag Knife to Cut Materials

While drag knives offer many advantages, there are also limitations and challenges to their use. One of the biggest challenges is the need for a high-quality cutting mat. A good cutting mat is essential to ensure that the blade cuts the material cleanly and does not damage the surface underneath.

Another challenge is finding the correct depth and pressure settings to cut the material. This can be very time consuming and requires trial and error to get right. Drag knives are also not suitable for cutting thicker materials like wood or metal.

Common troubleshooting questions for drag knives

Some common troubleshooting issues with drag knives include worn blades, improper depth and pressure settings, and calibration issues. To resolve these issues, the blades must be checked regularly for signs of wear and depth and pressure settings adjusted as needed. Calibration issues can be resolved by resetting or recalibrating the drag blade according to the manufacturer's instructions.

Safety precautions when using a drag knife

Safety should be your top priority when using a drag knife. Always remember to unplug the machine when replacing blades or performing maintenance work. Never leave equipment unattended when using it and always wear appropriate safety equipment such as gloves and goggles. Never touch the blade while it is still moving or attempt to suddenly stop the machine's movement. It’s also crucial to keep your work area tidy and free of obstructions.

Tips for cutting different materials with a drag knife

Cut vinyl with a drag knife

Vinyl is a commonly used material used for signs, decals, and stickers. The drag knife is an excellent tool for cutting vinyl because of its precise and intricate cuts. For best results, set the blade depth to the thickness of the vinyl and adjust the cutting speed to match the density of the material. Use a lower cutting speed for thin vinyl and a higher cutting speed for thicker vinyl. It's also crucial to make sure the vinyl is firmly attached to the cutting mat to prevent it from moving during the cutting process.

Discover paper and board drag technology

Paper and cardboard are commonly used materials in crafts and printing. The drag cutter can precisely cut intricate designs and shapes on paper and cardboard. To achieve precise cuts, the blade angle must be adjusted to match the density of the material. A sharper angle is better for thinner materials like tissue paper, while a blunter tip is better for thicker cardboard. It is also important to use an appropriate cutting mat to adequately support the blade.

Use a drag knife to cut leather

Leather is a popular material in the fashion world, and drag knives can be used to create intricate designs on leather products such as bags, belts, and shoes. When cutting leather with a drag knife, it's best to use a thicker blade and adjust the cutting speed and depth to match the thickness of the material. It's also crucial to make sure the leather is evenly stretched and securely fastened to the cutting mat. This will provide stability and prevent the material from shifting during the cutting process.

Troubleshoot common problems with drag knife cutting:

While drag tools are a great addition to any CNC machine, they can also present some common problems that can frustrate operators. These problems can include curved cuts, uneven edges and premature wear of the blade. Fortunately, there are solutions to these problems. For example, if the blade cuts unevenly, the cause could be insufficient blade pressure or a dull knife. Cleaning the blade and holder and adjusting the blade angle can resolve these issues. These are just a few examples, and a thorough understanding of each problem and solution can save operators valuable time and money.

Use drag tools to improve the efficiency of CNC machines:

Drag tools can make CNC machines more efficient by reducing setup time, increasing versatility and reducing the risk of material waste. Drag knives enable precise cutting at high speeds, eliminating the need for additional machines and reducing setup time between operations. The drag knife can also cut a variety of materials, expanding the range of materials used by CNC machine tools. Finally, drag knives minimize material waste generated during production, saving costs and reducing environmental impact. By effectively using drag tools, CNC operators can achieve greater productivity.

The drag tool tool for CNC cutting machines is about to come to an end here. If you still want to know more, please click to contact us, and we will have professional staff to answer you in detail as soon as possible!

For more information, please consult:

Email: info@aolcnc.com

Phone: +86-531-88620680

WhatsApp/We Chat: 0086-18560162709

youtube: https://www.youtube.com/channel/UCDiNQSjBR5DsAX9QfkWF7AA

Website: https://www.aolcnc.com/